Seal, screw connection having the seal, and use thereof

A technology for seals and bolts, applied in the field of seals, can solve problems such as difficult-to-clean gaps and protrusions, seals that are difficult to reach, pollution, etc., and achieve the effect of reducing the risk of assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

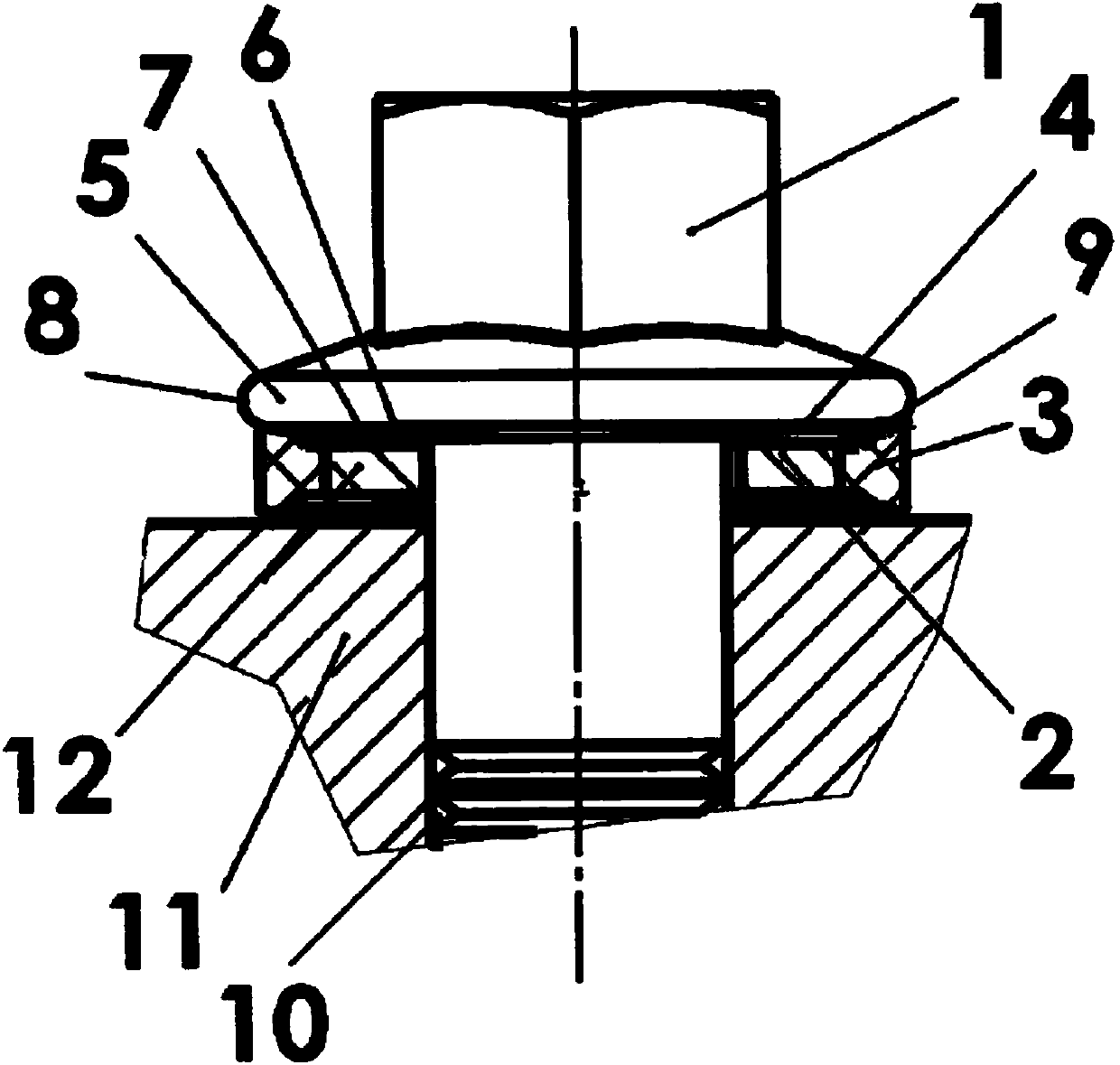

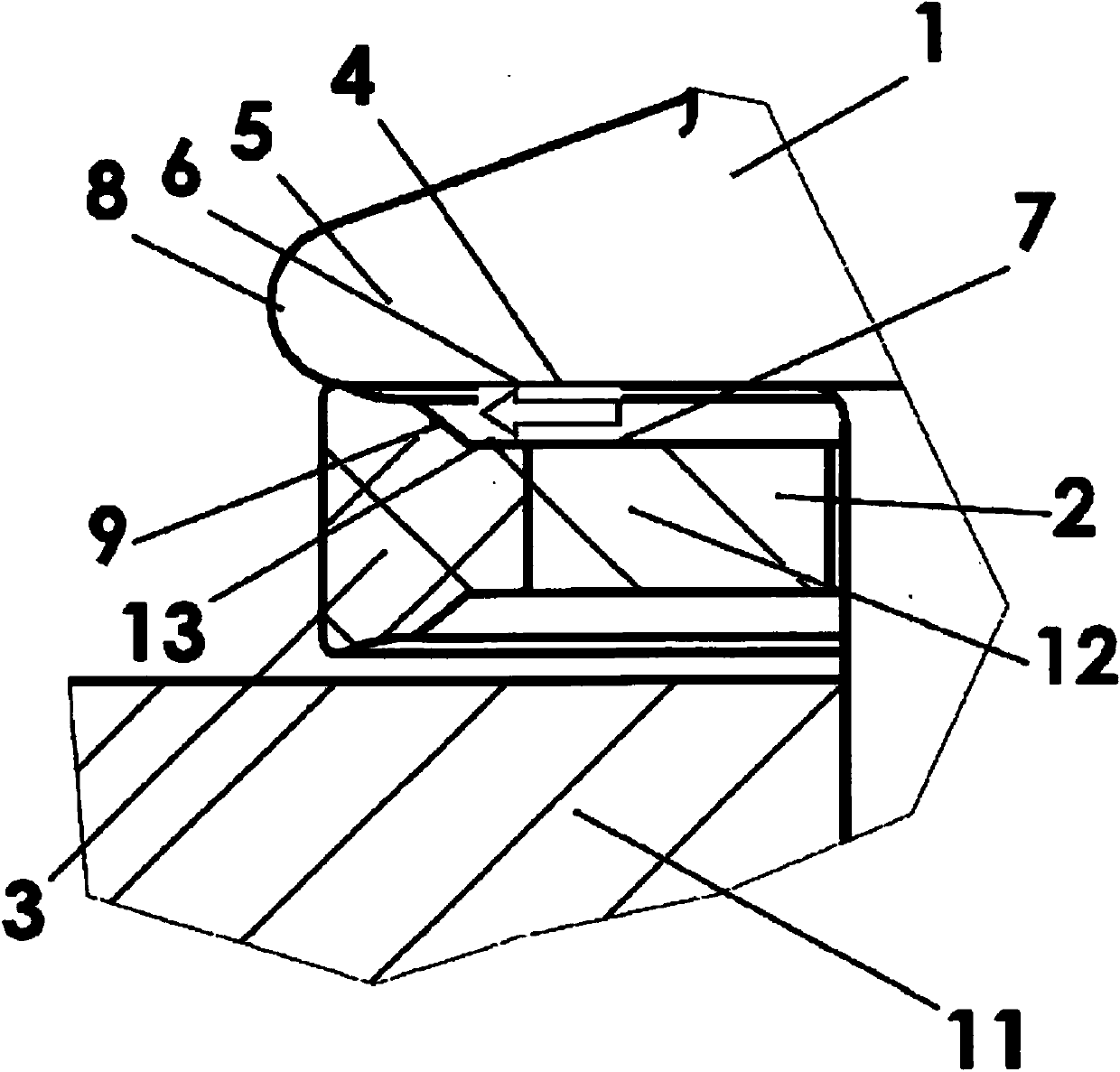

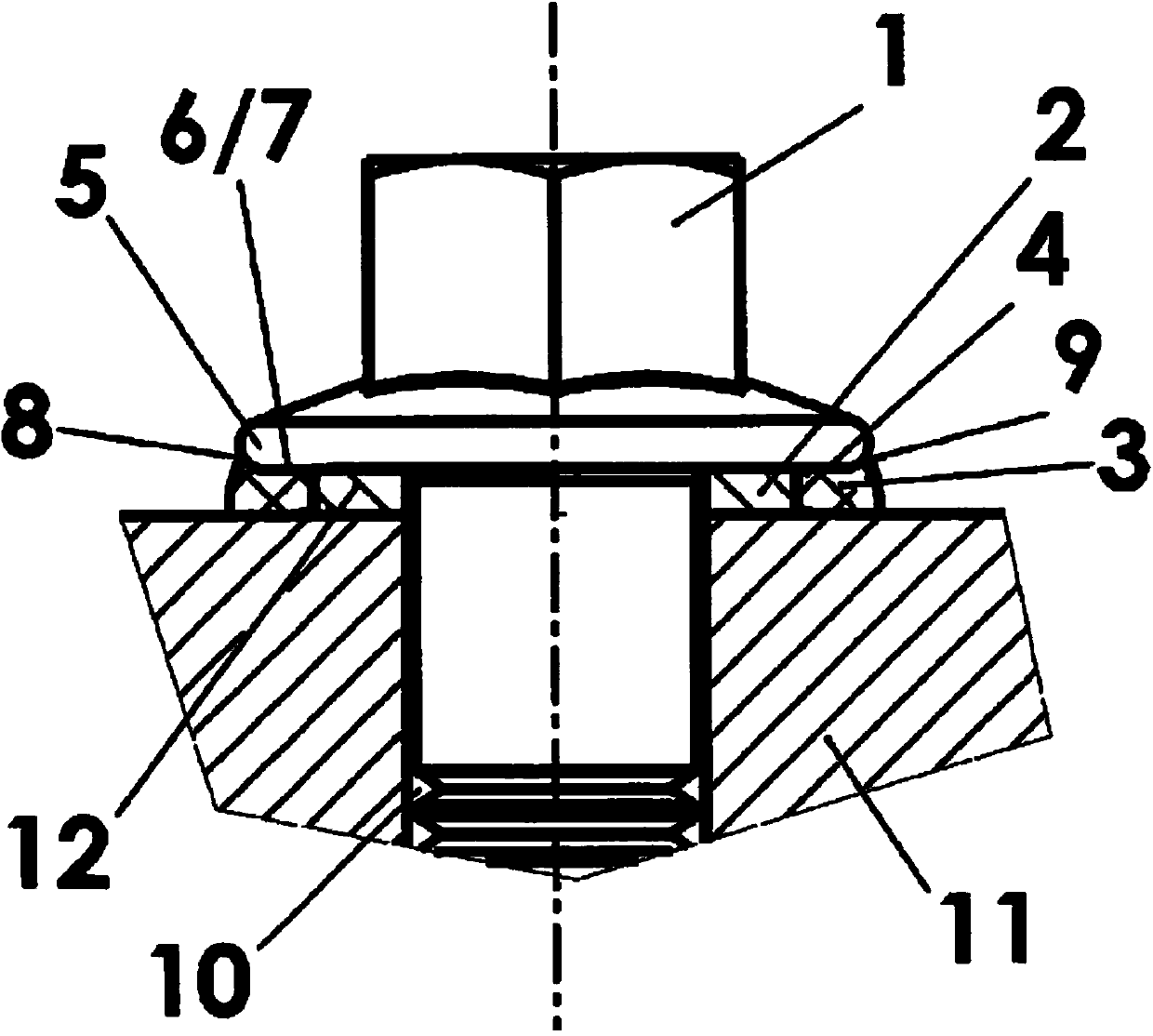

[0023] exist Figures 1 to 3 An example of a bolted connection including a seal is shown in .

[0024] In the present embodiment, the fastener 1 is configured as a bolt with a flange 5 , for example manufactured according to DIN EN1665. Furthermore, the seal comprises a gasket 2 for the fastener 1 located axially between the flange 5 of the fastener 1 and the machine element 11 . The gasket 2 comprises a centrally arranged metal flat ring 12 , the outer peripheral side of which is surrounded by a sealing lip 3 made of a rubber-elastic sealing material, such as NBR or FKM.

[0025] The fastener 1 comprises, on the side axially facing the washer 2 , a flange 5 with a bottom face 6 . In this way, the fastener 1 and the flange 5 are integrally made of the same material in such a way that they blend into each other. When the seal is used as intended, the bottom surface 6 of the flange 5 and the top surface 7 of the gasket 2 are in contact with each other in a hermetic manner, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com