Forged type pull plate and manufacturing method thereof

A manufacturing method and a technology of drawing plates, which are applied in metal processing equipment, cranes, etc., can solve problems such as difficult shaping, low fatigue resistance, and low utilization rate of raw materials, so as to improve safety performance, increase service life, and be beneficial to paint The effect of attachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

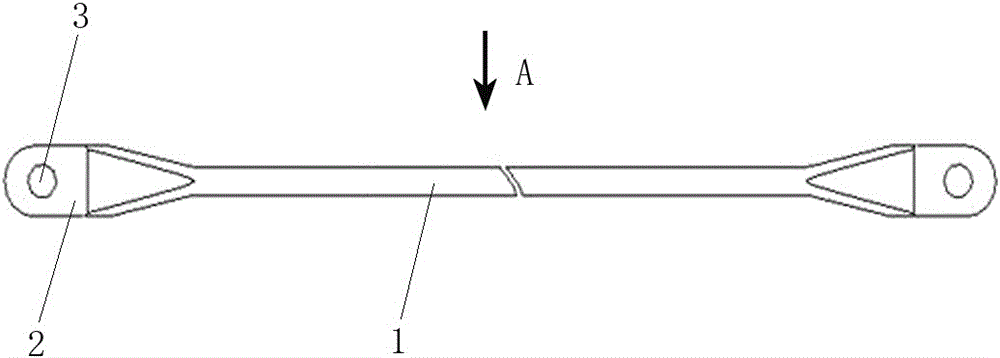

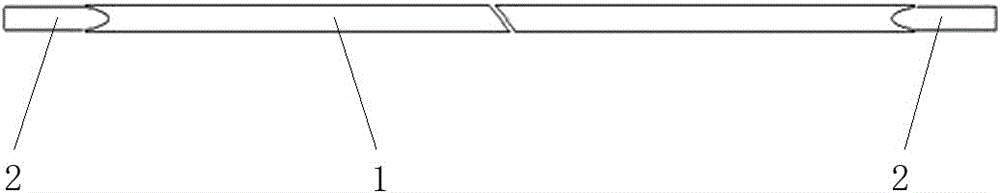

[0030] Such as figure 1 , figure 2 As shown, the forged pull plate includes a round steel main body 1, and the cross-sectional diameter of the round steel main body 1 is not less than 30 mm. Both ends of the round steel body 1 are respectively forged with pull plate joints 2 . A joint hole 3 is opened on the draw plate joint 2 . The pull plates can be connected by pin shafts.

[0031] The present invention also discloses a method for manufacturing a forged pull plate, which is suitable for the above-mentioned forged pull plate, and specifically includes the following steps:

[0032] Step 1: Take the round steel as the raw material, and cut the material to the required size;

[0033] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com