Laser output device and 3D printer

A laser output device and laser beam technology, applied in the field of 3D printing, can solve problems such as splashing, inability to guarantee part contour accuracy, and gasification of powder to be formed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

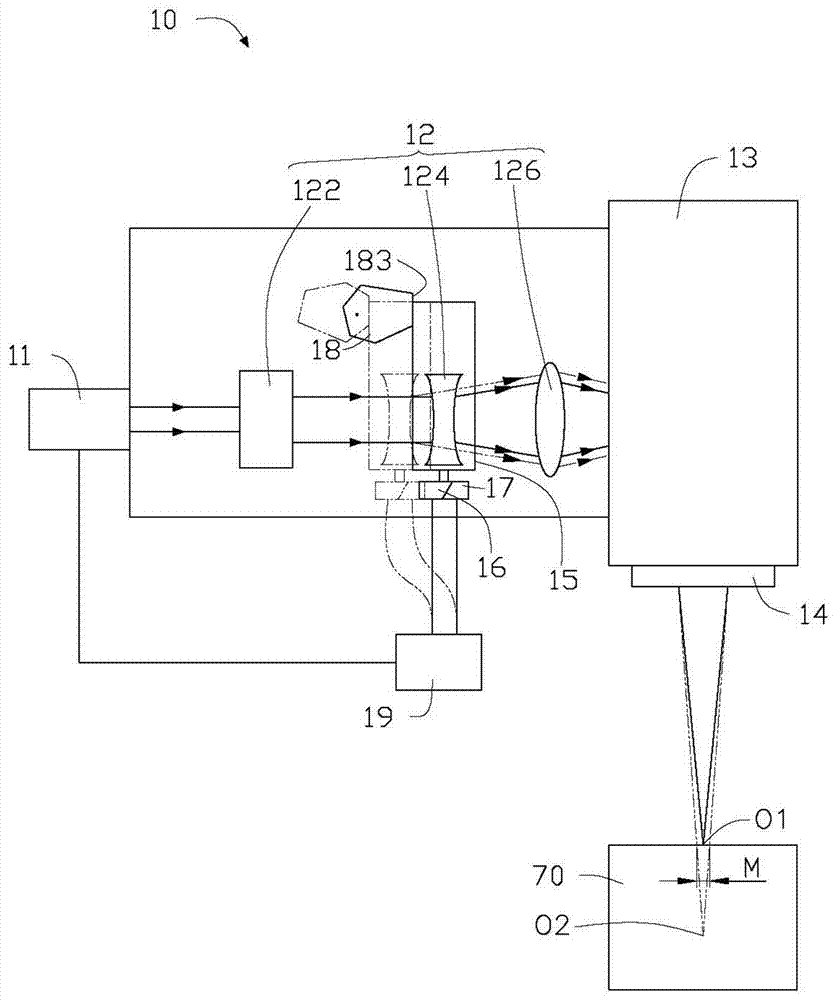

[0027] see figure 1 , is the laser output device 10 provided in the first embodiment of the present invention. The laser output device 10 includes a laser 11 , an optical element 12 , a laser scanning galvanometer 13 , a focusing lens 14 , a storage device 15 , a translation device 16 , a position sensing device 17 , a stopper device 18 , and a controller 19 .

[0028] The laser 11 is used to generate a laser beam. The optical element 12 includes a laser beam expander 122 , a concave lens 124 and a convex lens 126 . The laser beam expander 122 is used to expand the laser beam generated from the laser 11 . The concave lens 124 is used to diverge the laser beam from the laser beam expander 122 . The convex lens 126 is used to converge the laser beam from the concave lens 124 . The laser scanning galvanometer 13 is used to deflect the laser beam from the convex lens 126 at a certain angle and output it to a region to be printed. The focusing lens 14 is arranged at the front ...

no. 2 approach

[0036] see image 3 , is the laser output device 20 provided in the second embodiment of the present invention. The laser output device 20 includes a laser 21 , an optical element 22 , a laser scanning galvanometer 23 , a focusing lens 24 , a storage device 25 , a translation device 26 , a position sensing device 27 , a stopper device 28 , and a controller 29 .

[0037] The laser 21 is used to generate a laser beam. The optical element 22 includes a laser beam expander 222 , a concave lens 224 and a convex lens 226 . The laser beam expander 222 is used to expand the laser beam generated from the laser 21 . The concave lens 224 is used to diverge the laser beam from the laser beam expander 222 . The convex lens 226 is used to converge the laser beam from the concave lens 224 . The laser scanning galvanometer 23 is used to deflect the laser beam from the convex lens 226 at a certain angle and output it to a region to be printed. The focusing lens 24 is arranged at the front...

no. 3 approach

[0045] see Figure 4 , is the laser output device 30 provided in the third embodiment of the present invention. The laser output device 30 includes a laser 31 , an optical element 32 , a laser scanning galvanometer 33 , a focusing lens 34 , a storage device 35 , a translation device 36 , a position sensing device 37 , a stopper device 38 , and a controller 39 .

[0046] The laser 31 is used to generate a laser beam. The optical element 32 includes a laser beam expander 322 , a concave lens 324 and a convex lens 326 . The laser beam expander 322 is used to expand the laser beam generated from the laser 31 . The concave lens 324 is used to diverge the laser beam from the laser beam expander 322 . The convex lens 326 is used to converge the laser beam from the concave lens 324 . The laser scanning galvanometer 33 is used to deflect the laser beam from the convex lens 326 at a certain angle and output it to an area to be printed. The focusing lens 34 is arranged on the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com