Special polishing device for polishing wheel arc finishing and having automatic dust-absorbing function

An automatic vacuuming and polishing wheel technology, which is applied in the field of polishing machines, can solve the problems of high operating speed of the needle bar, time-consuming and labor-intensive manual trimming, and poor processing quality. It achieves good consistency, simple structure, and convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

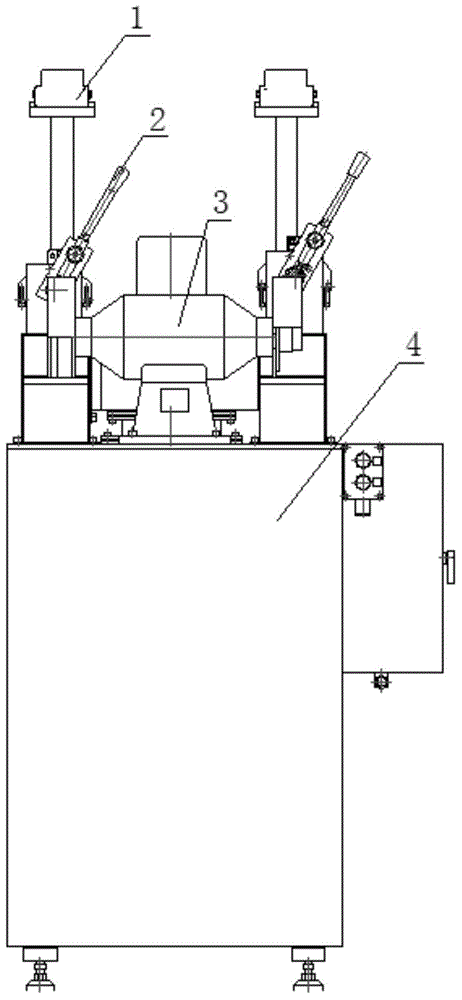

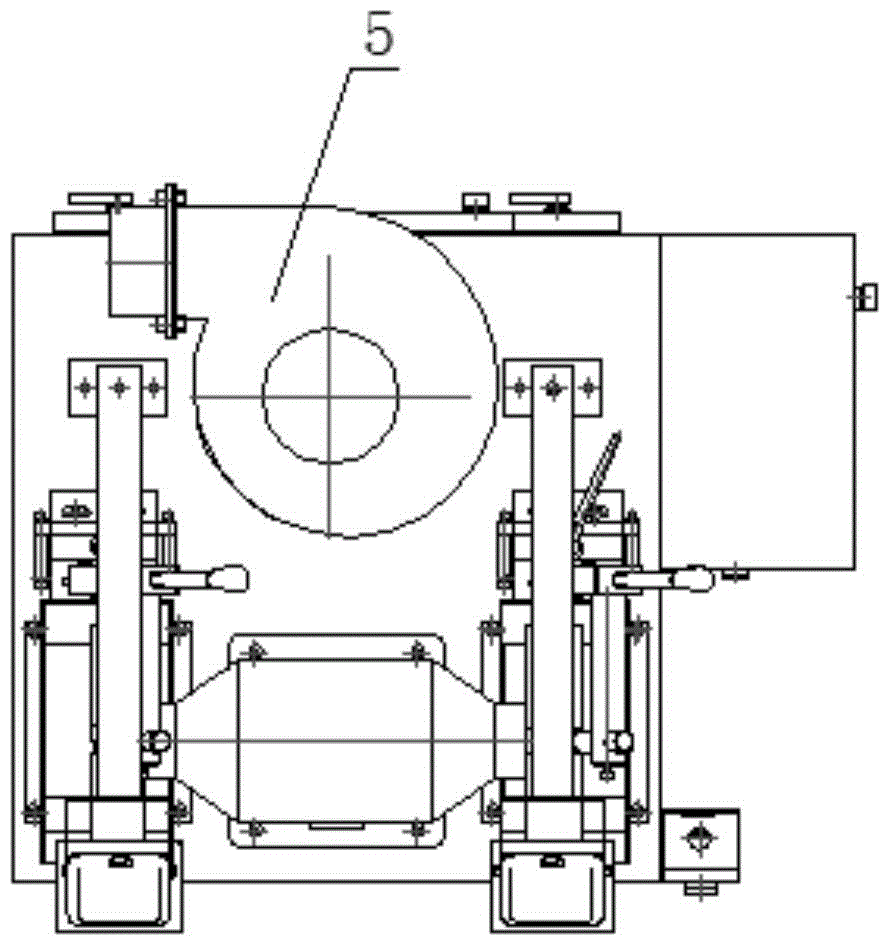

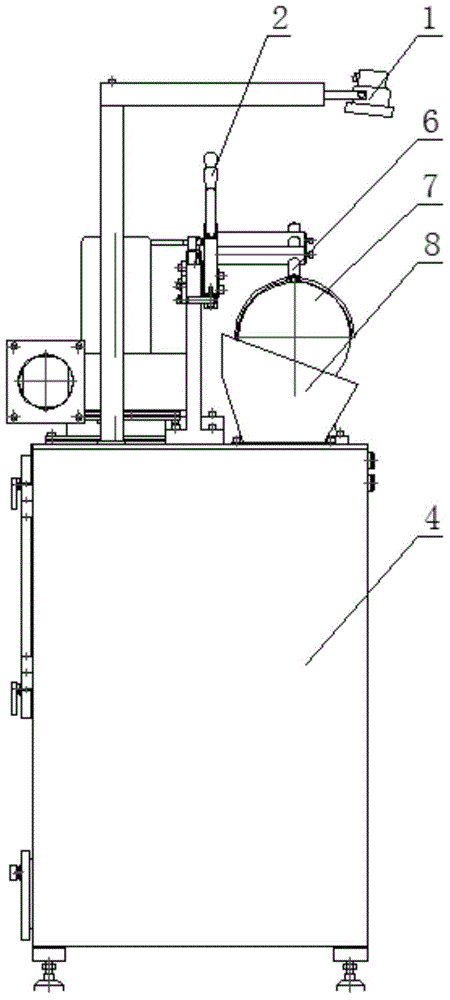

[0020] A special polishing equipment for automatic vacuuming and polishing wheel trimming arc, including a base 4, a motor 3 and a sponge wheel 7, a motor is installed on the upper surface of the base, the motor is connected to and drives the sponge wheel, on the base behind the sponge wheel A vertical plate 9 is installed, and a sponge wheel finisher is installed on this vertical plate, and this sponge wheel finisher includes fork 2 and finishing head 6. Make a vertical long hole 11 on the vertical plate, the lower end of fork is installed on this long hole by bolt. A limit rod 10 is installed on the left and right sides of the vertical plate top, and the fork is positioned between the two limit rods. The fork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com