Beating type vacuum leakage preventing apparatus with crawler type vacuum pumping filter

A vacuum filtration, crawler-type technology, used in filtration separation, moving filter element filters, separation methods, etc., can solve the problems of air leakage, poor vacuuming effect, insufficient solid-liquid separation of materials, etc., to ensure dehydration. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

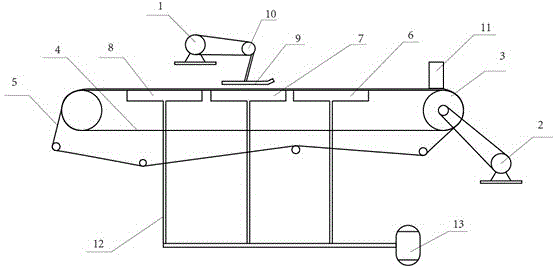

[0010] A slapping vacuum leakage prevention device for a crawler-type vacuum filter, comprising a vacuum filter, the vacuum filter includes a frame, a motor, a roller, and a crawler, the frame is equipped with a roller 3, and the roller is provided with a crawler 4. Filter cloth 5 is provided on the outer layer of the crawler belt, and a distributor 11 is provided at one end of the upper side of the crawler belt. Link to each other; the top of the second stage vacuum box 7 and the third stage vacuum box 8 is provided with a beating device, and the beating device includes a beater 9 and a vibrating motor 1, and the beating device 9 is connected with the vibrating motor 1 by a transmission mechanism 10; The flapper 9 bottom surfaces are horizontal, and the edge of the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com