Efficient organic recovered solvent purification device and process

A technology for recovering solvents and purification devices, which is applied in the field of high-efficiency organic solvent recovery and purification devices, can solve the problems of insufficient processing efficiency, discontinuous processing, waste of resources, etc., and achieve obvious economic and environmental benefits, high material utilization efficiency, The effect of saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Describe embodiment in detail in conjunction with accompanying drawing,

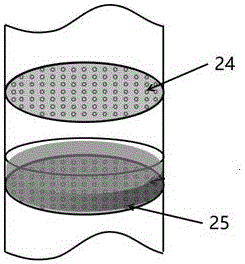

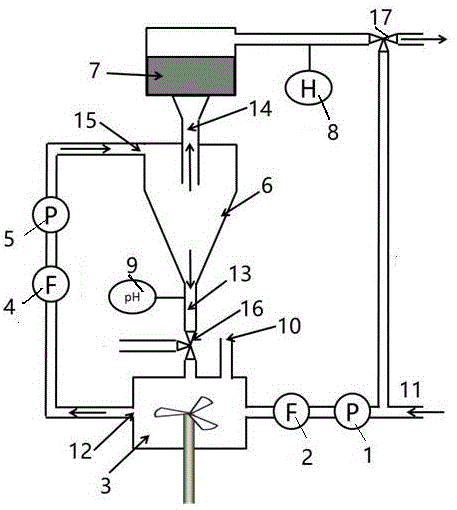

[0014] An embodiment of the present invention is a high-efficiency organic recovery solvent purification device and process, which is characterized in that: the feed port of the mixing reactor 3 is provided with a feed pump 1, a feed-liquid flow meter 2, and a liquid at the outlet of the mixing reactor Port 12 is communicated with a pipeline, and the pipeline is connected in series with a reaction mixture flowmeter 4, a reaction mixture circulation pump 5, and the other end of the pipeline is communicated with the hydrocyclone inlet 15 of the hydrocyclone 6, and in the mixed reaction The top of the device is provided with a reaction port, the reaction port is provided with a three-way valve, one passage is the vent passage, and the other passage is connected with the heavy phase circulating liquid outlet 13 of the hydrocyclone, and a pH monitoring instrument is installed at the heavy phase circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com