Robot-assisted visual assembly system for PCB (Printed Circuit Board)

A robot-assisted, PCB board technology, applied in electrical components, electrical components and other directions, can solve the problems of waste of human resources, low production efficiency, uneven product quality, etc., to ensure product quality and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

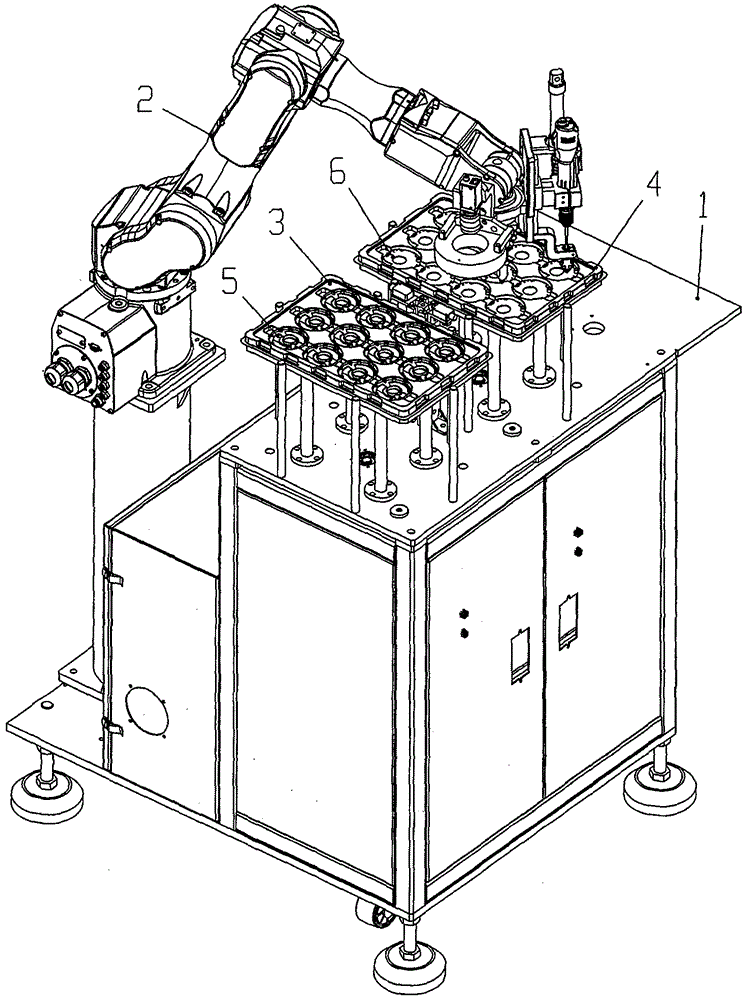

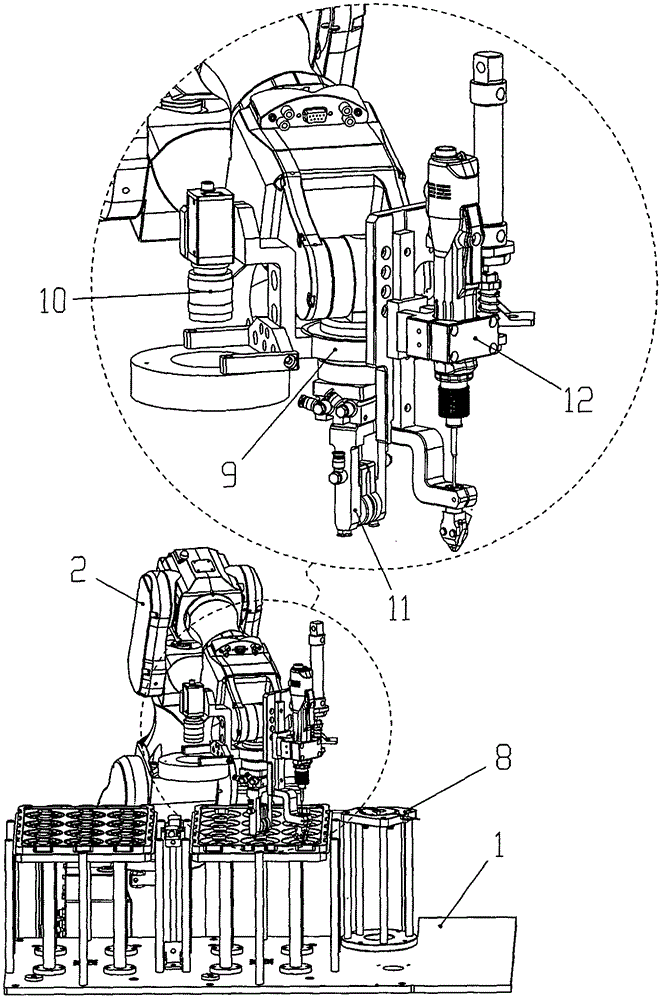

[0029] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a robot-assisted visual assembly system for PCB boards, which is used to fasten the PCB boards to the brackets with screws, rely on machine vision to determine the positions of the PCB boards and the brackets, and use the locking screw mechanism to realize the assembly of the PCB boards. The connection with the bracket is fully automatic, realizing unmanned operation, accurate action and reliable connection.

[0030] figure 1 It is a structural schematic diagram of a specific embodiment of the robot-assisted vision assembly system for PCB boards of the present invention, figure 2 , 3 It is a structural schematic diagram of the robot-assisted visual assembly system of the PCB board of the present invention in another perspective, Figure 4 It is a structural schematic di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com