Tuner components for antenna isolators that ensure the quality of high-frequency signal transmission

A high-frequency head and isolator technology, applied in color TV parts, TV system parts, electrical components, etc., can solve the problems of low mass production efficiency, poor product consistency, unfavorable TV sets, etc. High chemical production efficiency, low cost, good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

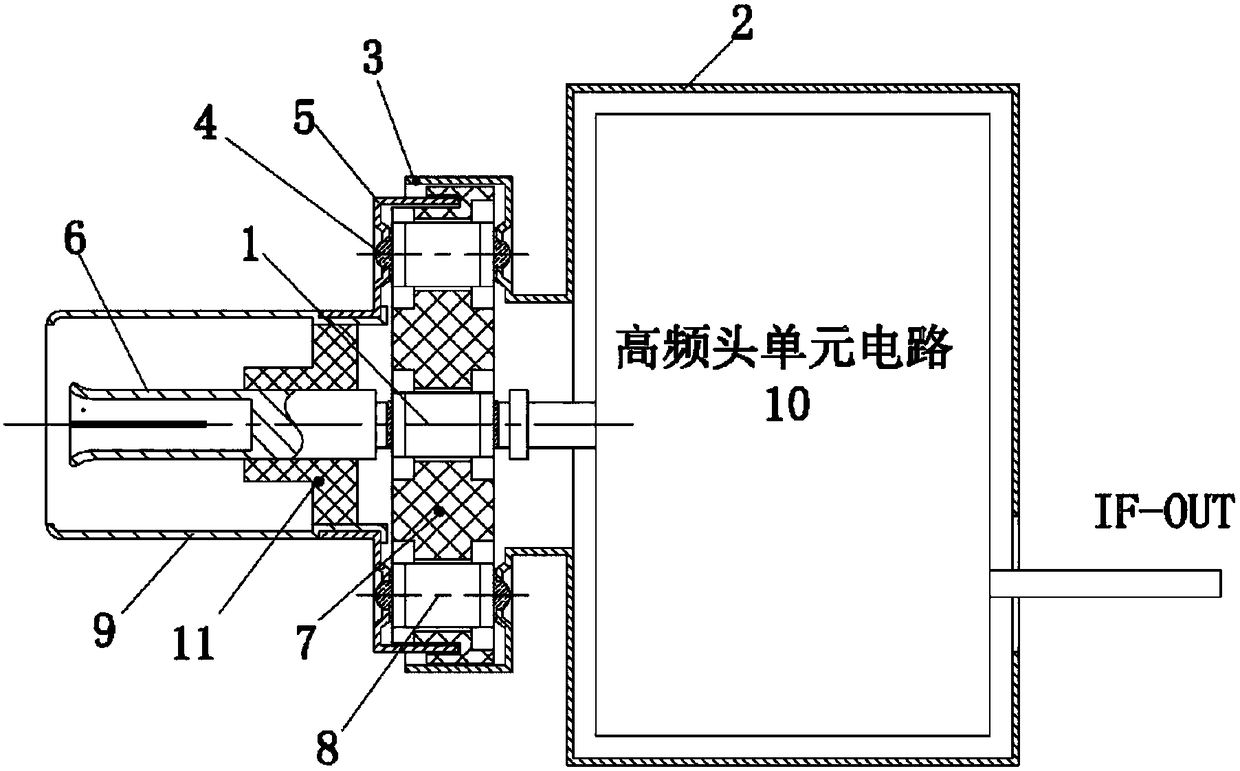

[0028] Such as figure 1 , the tuner assembly for television of the present embodiment comprises: an outer shield 2, a tuner unit circuit 10 located in the outer shield 2; the signal input end of the tuner unit circuit 10 is isolated from an antenna The signal output terminal of the antenna isolator is connected; the antenna isolator includes: large and small shielding covers with opposite openings, the opening end of the small shielding cover 5 extends into the opening of the large shielding cover 3; the outer side of the small shielding cover 5 is provided There is a shielding layer joint 9, and the core wire joint 6 of coaxial distribution is fixedly arranged in the shielding layer joint 9, and the rear port of the large shielding cover 3 is connected with the front opening of the outer shielding cover 2; There are 4, 5 or 6 ground wire DC blocking capacitors 8 and a signal DC blocking capacitor 1; a plurality of through holes are symmetrically arranged on the large and smal...

Embodiment 2

[0034] The production method of the antenna isolator in the tuner assembly of above-mentioned embodiment 1, it comprises the steps:

[0035] A. Fix solder paste on the two electrodes of each capacitor, or on the large and small shields;

[0036] B. The core wire joint is fixed in the shielding layer joint through the insulating block 11, and at the same time, the inner side end of the shielding layer joint is fixedly fitted in the installation hole of the large shielding case or the small shielding case;

[0037] C. The large and small shielding covers are arranged horizontally opposite each other, and the shielding layer connectors are set downwards, and the DC blocking capacitors for each line are respectively arranged between multiple sets of relative through holes on the large and small shielding covers Between, the signal DC blocking capacitor is set on the inner end of the shielding layer connector;

[0038] D. Send it to the reflow soldering device to complete the solder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com