A low-voltage power supply generating circuit, method and integrated circuit

A low-voltage power supply and circuit generation technology, which is applied in the direction of adjusting electrical variables, instruments, control/regulation systems, etc., can solve the problems of inaccurate output, unstable low-voltage power supply, and increased circuit cost, and achieve the effect of solving interdependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

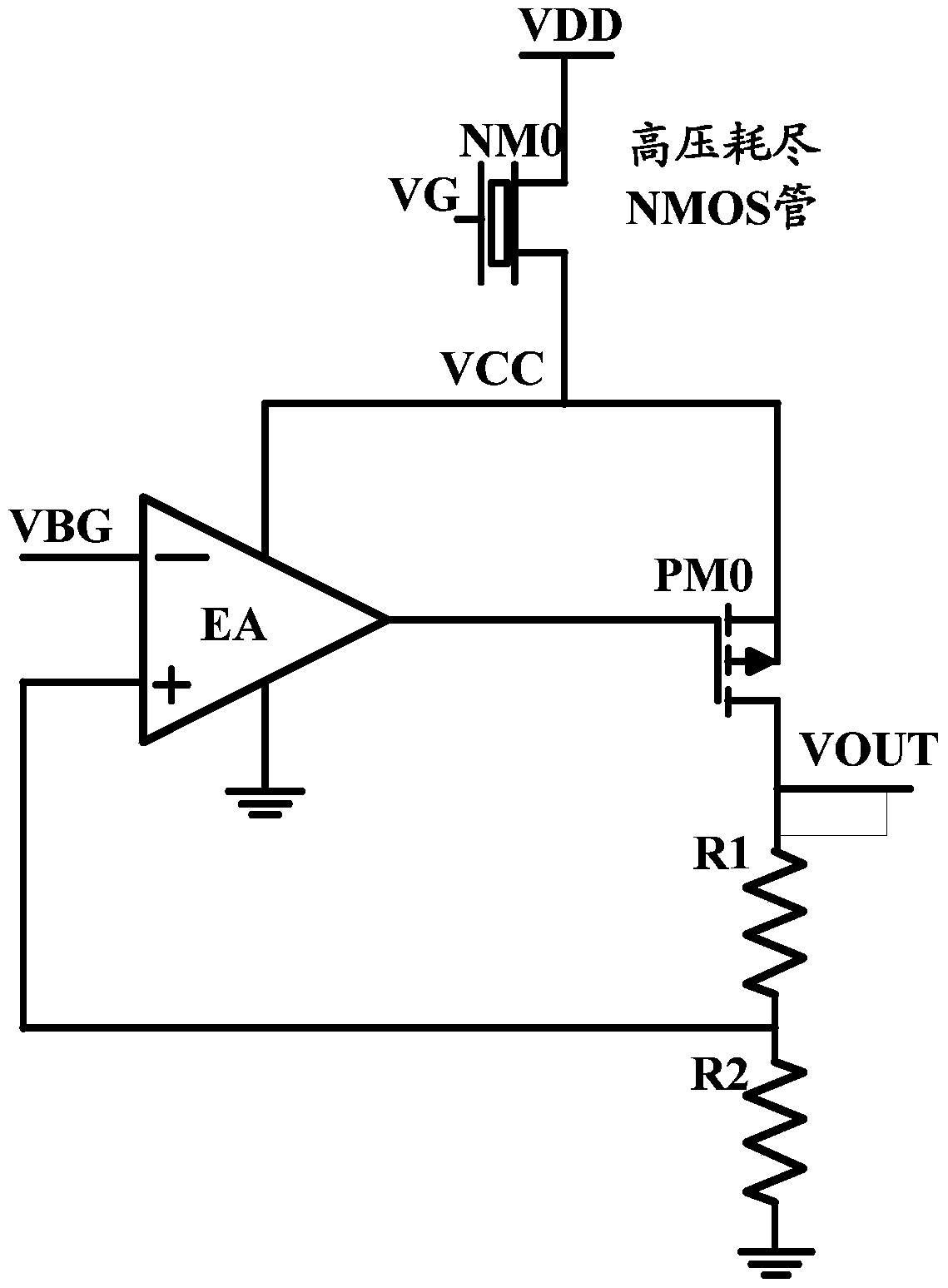

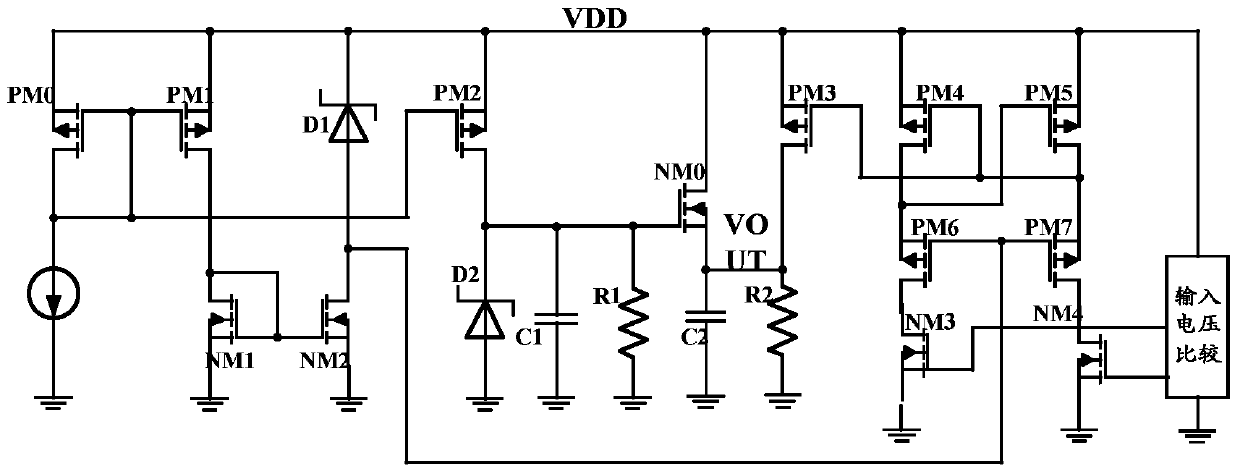

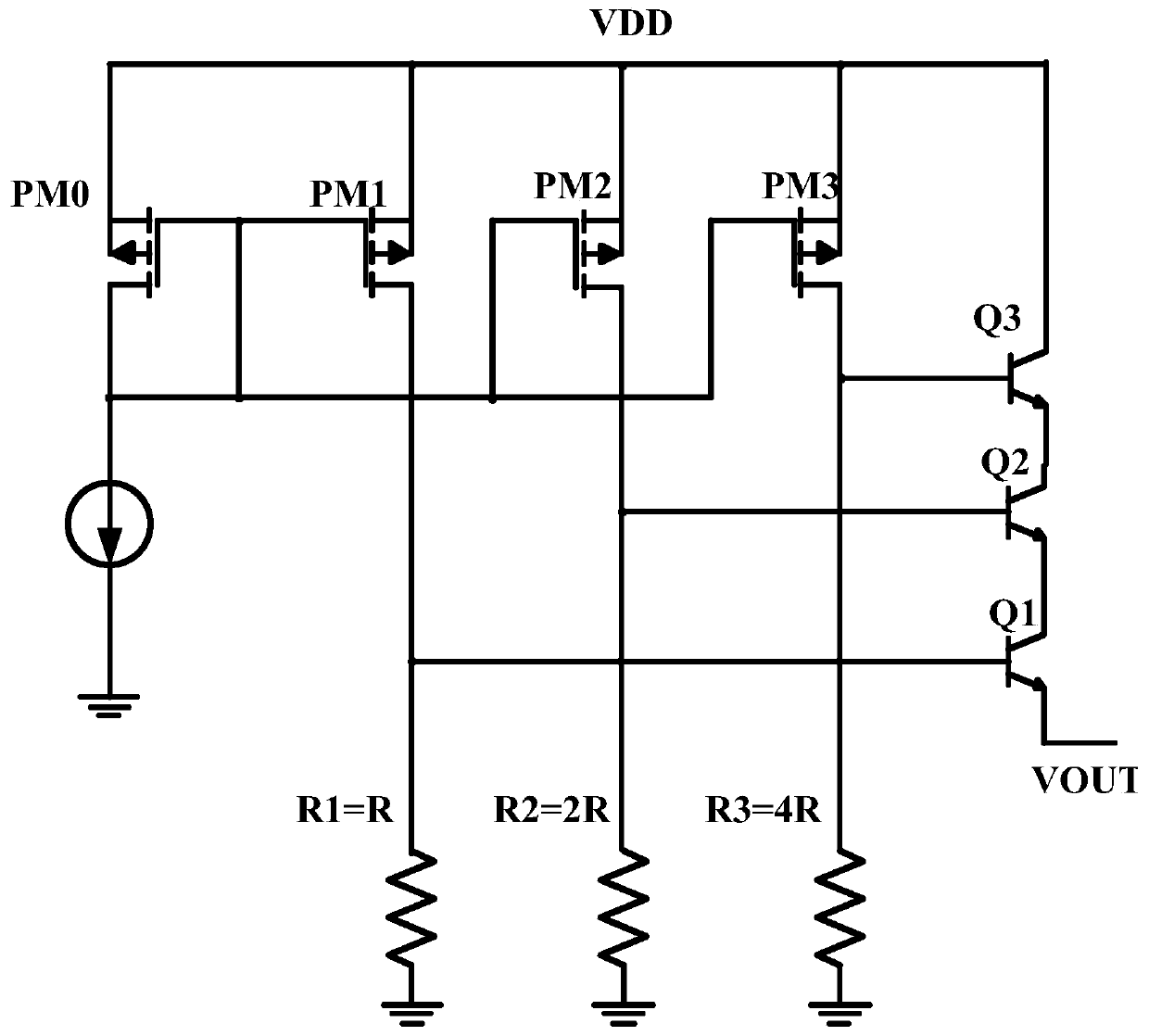

[0040] At present, the realization method of converting high-voltage power supply into low-voltage power supply is generally to directly convert high-voltage power supply to obtain low-voltage power supply, such as figure 2 , 3 , The circuit shown in 4, although this kind of scheme can transform the high-voltage power supply into a low-voltage power supply, the low-voltage power supply generated is not stable enough and will change with the change of the load current; at the same time, the output also depends on the characteristics of the device such as the Zener tube The stable voltage value and the threshold value of the N tube, etc., the output is not accurate, so it cannot be applied to power chips with higher requirements. specifically, figure 2 In the circuit shown, the output voltage depends on the clamp value of Zener tube D2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com