γ dose rate meter automatic rotation verification device

A technology of automatic rotation and gamma dose rate, which is applied in the direction of instrumentation and radiation measurement, can solve the problems of low work efficiency and high risk of accidental exposure of personnel, so as to reduce the number of times of entering and exiting the irradiation room, reduce the risk of accidental exposure, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

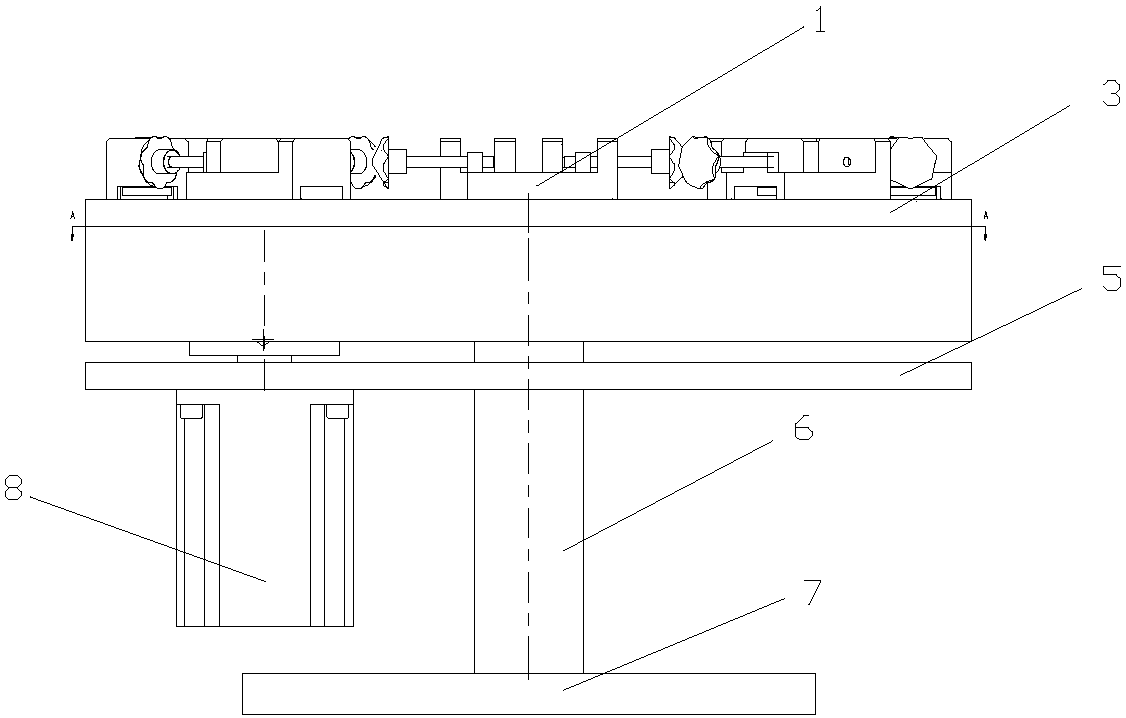

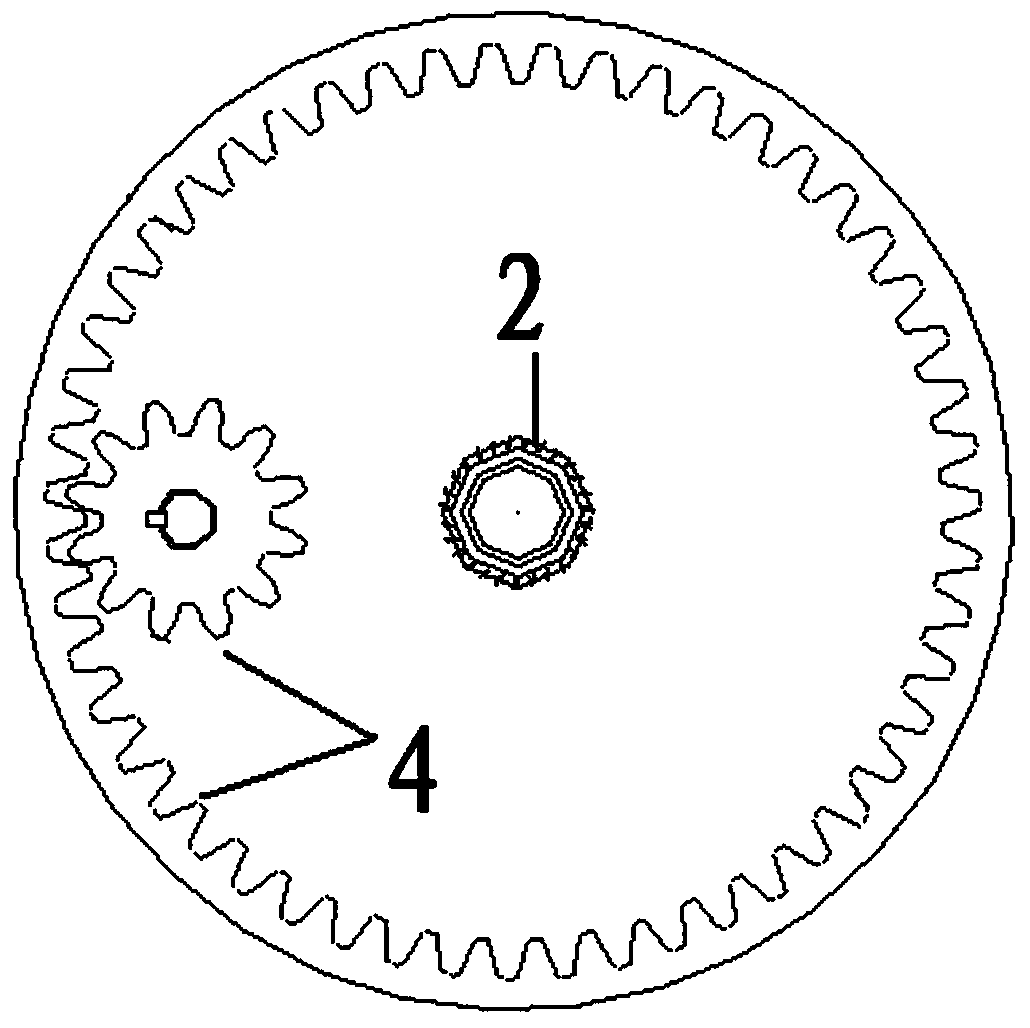

[0026] like figure 1 As shown, the gamma dose rate instrument automatic rotation verification device of the present invention includes an instrument clip, an instrument tray, and also includes a bearing, a main support rod, a gear, a motor, a motor fixing plate, and a verification platform; N instrument clips are evenly distributed and fixed on the instrument tray On the top, the gear is fixed under the instrument panel and on the motor, and the main support rod is connected to the instrument tray through bearings; N≥2; preferably N=8;

[0027] The instrument clamp is a vise-type fixture, one end of which is fixedly connected to the instrument tray, and the other end is a movable slider connected to the screw, which controls the forward and backward of the instrument clamp through the screw;

[0028] The instrument ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com