Method for detecting trace amount of nitrogen in gray pig iron

A gray cast iron, trace technology, applied in the field of detection of metal materials, can solve the problems of restricting the progress of the analysis process, long analysis cycle, high cost, etc., and achieve the effect of reasonable method, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

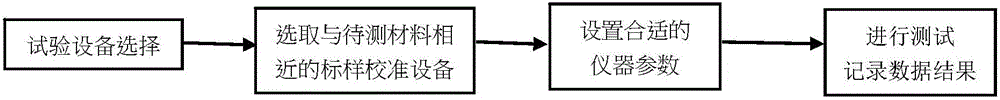

[0014] A method for detecting trace amounts of nitrogen in gray cast iron, the steps of which are:

[0015] a. Sample preparation: First, quench the gray cast iron sample: heat it to 750°C, heat it for 3 hours and then take it out of the furnace to cool it in water to change the surface structure of the sample to a semi-white state, then cut and polish the sample and flatten it;

[0016] b. Immediately use the spark source atomic emission spectrometer for spectral analysis. The instrument parameters are selected as follows: the wavelength of the nitrogen analysis line is 149.270nm, the argon flushing time is 2s, the pre-combustion time is 10s, and the integration time is 13s; detect the content of trace nitrogen.

[0017] Therefore, the content of trace nitrogen elements in gray cast iron can be determined quickly and accurately.

[0018] The above is only a specific embodiment of the present invention, but the scope of protection of the present invention is not limited theret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com