Electronic component transparent medium turntable bearing testing and automatic wiping method

A technology of electronic components and transparent media, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems that components cannot be tested, debugged, difficult to operate, and probe life is short , achieve the effect of shortening the test action time, compact structure and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

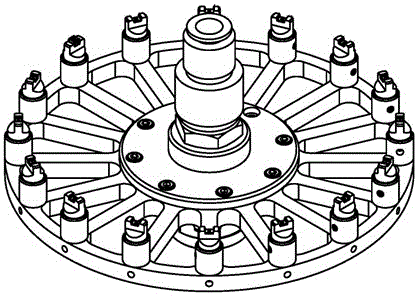

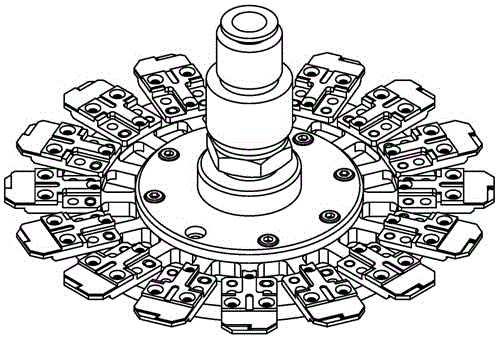

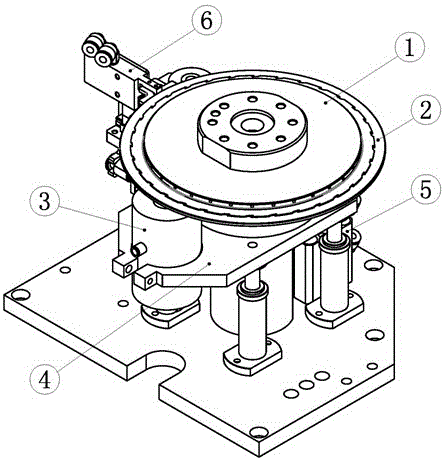

[0019] Such as image 3 As shown, a method for bearing test and automatic wiping of a transparent medium turntable for electronic components in the present invention includes a positioning turntable 1, a transparent medium turntable 2, a test probe 3, a turntable fixing seat 4, a cylinder 5, and an automatic wiping device 6, wherein the transparent medium The turntable 2 and the test probe 3 are fixed on the turntable fixing seat 4; wherein the turntable fixing seat 4 is connected with the cylinder 5, and the cylinder 5 drives the turntable fixing seat to move downward, thereby driving the transparent medium turntable 2 and the test probe 3 to separate from the positioning turntable 1; The automatic wiping transparent medium turntable device 6 automatically cleans the transparent medium turntable 2 after the transparent medium turntable 2 is separated from the positioning turntable 1; after the cleaning is completed, the cylinder 5 drives the turntable fixing seat 4, the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com