Ship steel plate curved surface dimension on-line measurement system and method

A measurement system and measurement method technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of inability to realize the surface fitting and detection of ship steel plates, and no online detection function, so as to improve the automation level and efficiency, reduce The effect of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

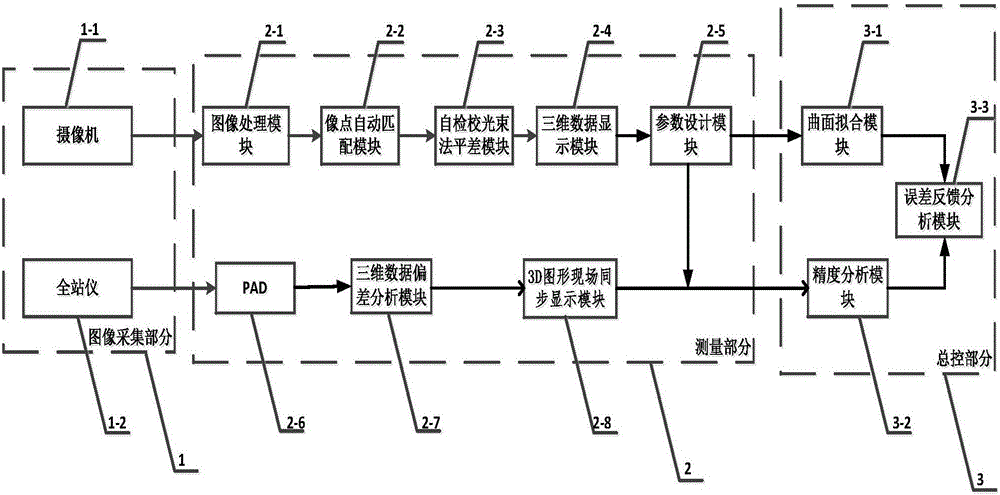

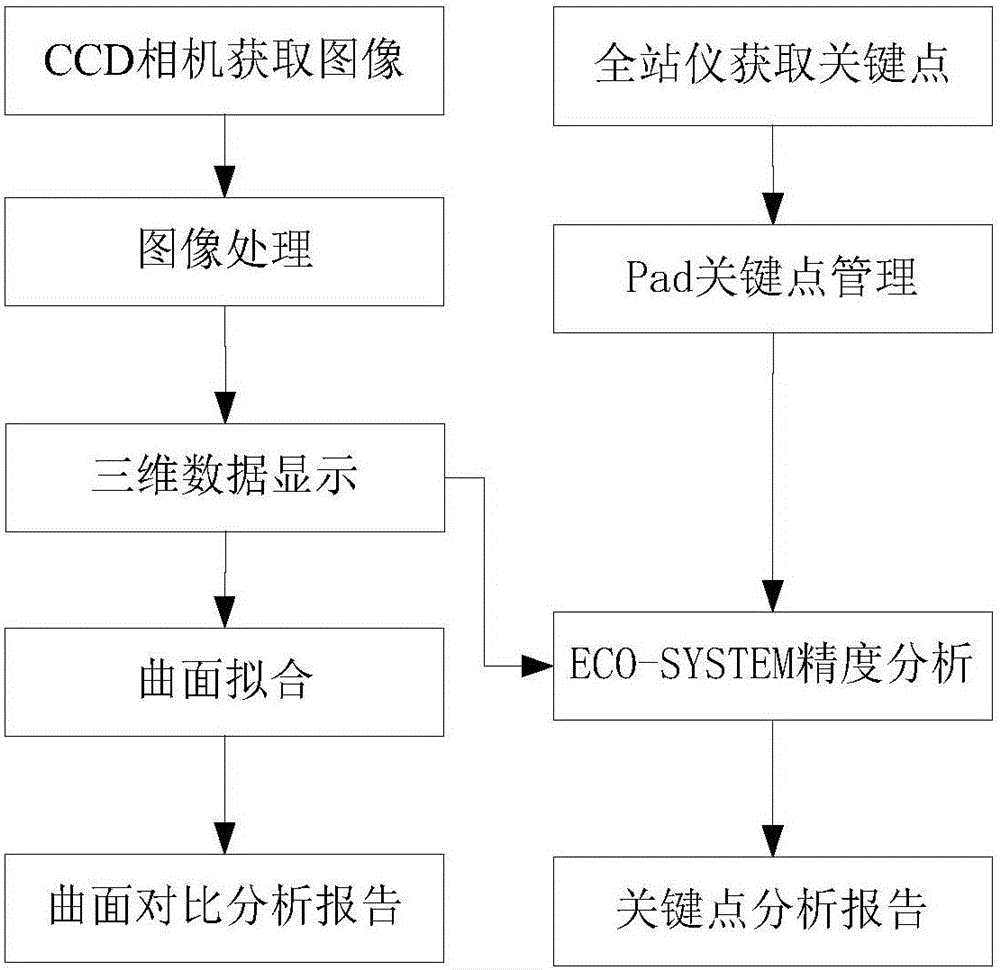

[0042] Such as figure 1Shown is a schematic diagram of the system structure of an embodiment of the present invention. Wherein, 1 is an image acquisition part, including a CCD camera 1-1 and a total station 1-2. Measurement part 2 includes: image processing module 2-1, image point automatic matching module 2-2, self-checking beam adjustment module 2-3, three-dimensional data display module 2-4, parameter design module 2-5, PAD2- 6. Three-dimensional data deviation analysis module 2-7, 3D graphic on-site synchronous display module 2-8. The general control part 3 includes: a surface fitting module 3-1, an accuracy analysis module 3-2, and an error feedback analysis module 3-3. The entire measurement system is a real-time online measurement system, which can realize the measurement of key points and curved surfaces on the curved surface of the ship's steel plate, greatly improving the measurement efficiency and accuracy of the ship's steel plate.

[0043] The above-mentioned C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com