Handheld Portable Fabric Density Detection System

A technology of fabric density and detection system, applied in the field of fabric optical detection system, can solve the problems of reducing the production efficiency of the fabric process, unable to achieve online automatic measurement, large error of weft density value, etc., and achieves the realization of online automatic measurement and compact structure. , easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

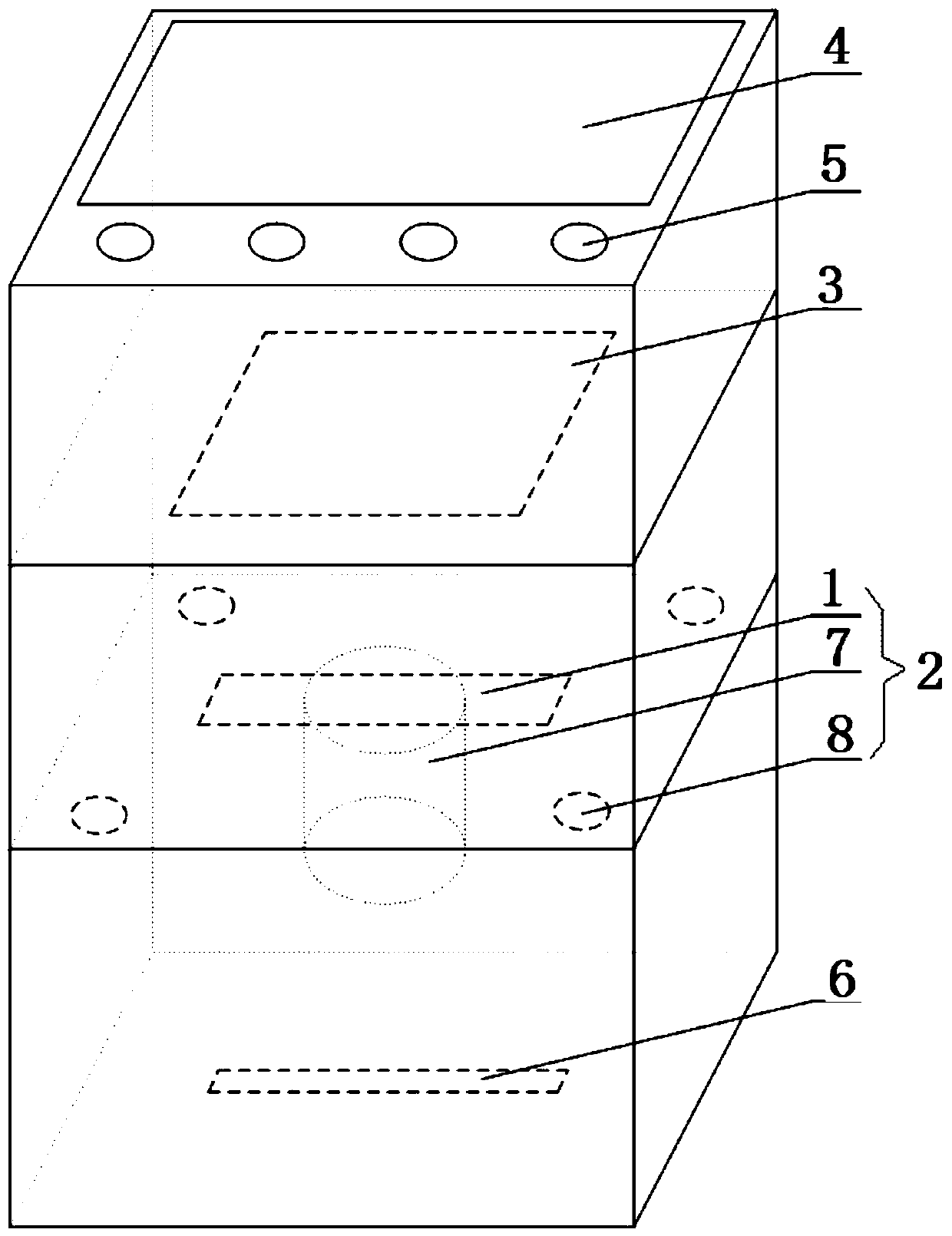

[0027] In this example, see figure 1 and figure 2 , a hand-held portable fabric density detection system, mainly includes a sample carrying platform and a sample optical recognition system 2 arranged in the equipment box, the sample to be tested is fixedly arranged on the sample carrying platform, and an image acquisition system is arranged above the front of the sample carrying platform Port 6, the sample carrying platform is equipped with a sample installation port device, through which the sample to be tested can be fixed on the sample carrying platform. The sample to be tested includes the fabric to be tested and the reference test object. The sample optical recognition system 2 mainly It is composed of an image sensor 1, a micro optical lens 7 and an optical path compensation system 8. The micro optical lens 7 is arranged directly above the image collection port 6, and the image sensor 1 uses the micro optical lens 7 to pass through the image collection port 6 to collect...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

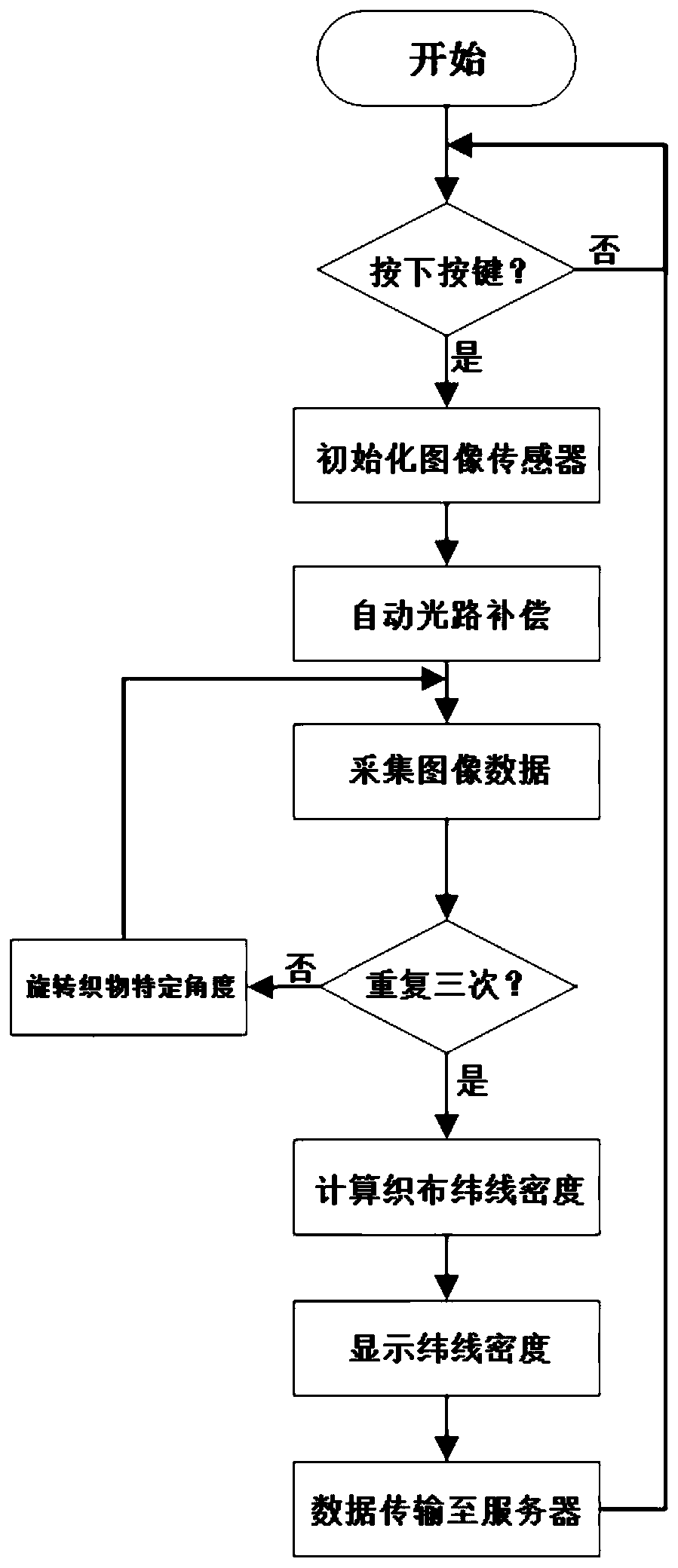

[0045] In this embodiment, the sample carrying platform can also perform horizontal rotation at a set angle, and the orientation of the sample to be tested can be adjusted as required. When the processor 3 controls the optical recognition system 2 to collect the image of the fabric sample to be tested, each acquisition After an image of the fabric sample to be tested, the sample carrying platform is rotated by a specific angle by driving the actuator to adjust the orientation of the sample to be tested, and then the image of the fabric sample to be tested is collected, and the orientation adjustment steps of the sample to be tested and the corresponding image acquisition are repeated Step three times, the processor 3 calculates the weft thread density of the fabric according to the rotation angle of the fabric sample to be tested and the image data of the fabric sample to be tested. In this emb...

Embodiment 3

[0047] This embodiment is basically the same as the previous embodiment, and the special features are:

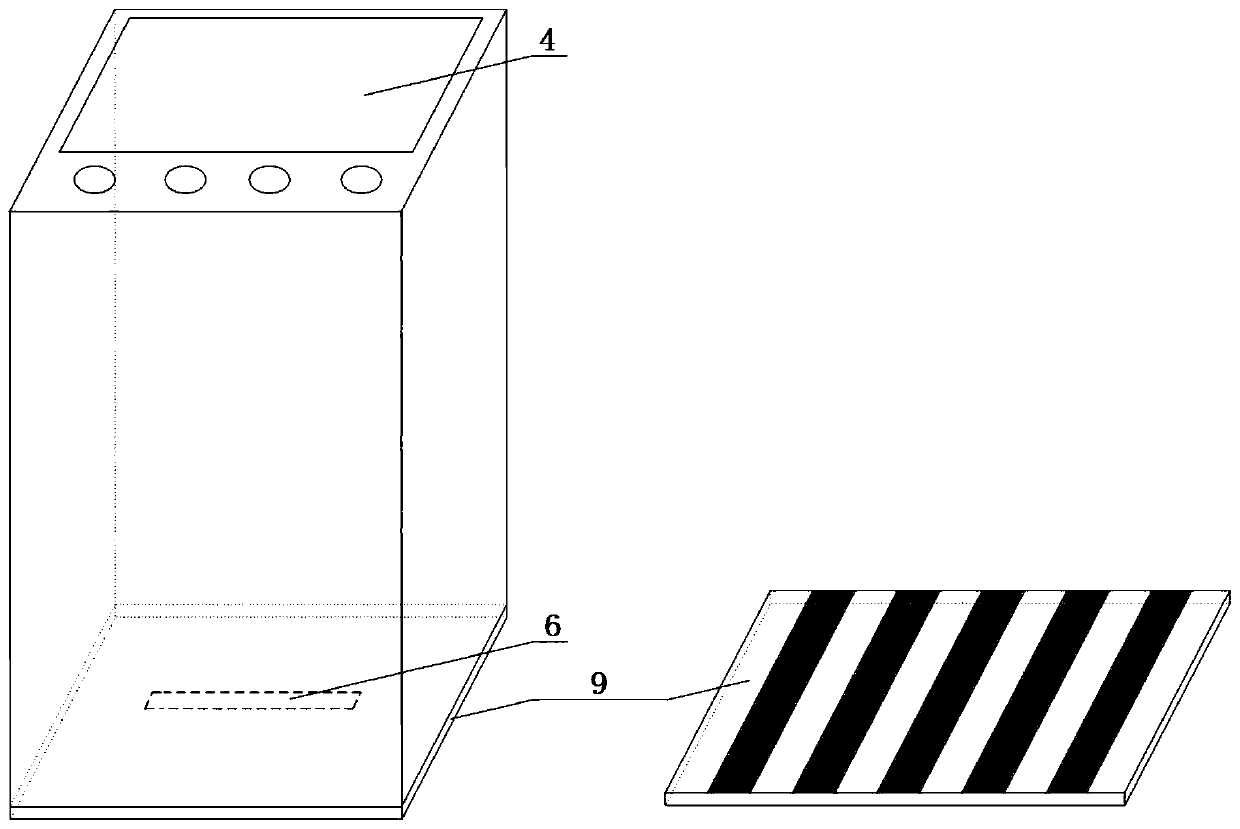

[0048] In this example, see image 3 and Figure 4 , the sample optical recognition system 2 is manually focused to adjust the focus of the optical recognition system 2, using the black and white stripe test plate 9 as a reference test object for focusing, and fixing the reference test object to be tested on the sample carrying platform through the sample installation port device Above, after the user presses the focus button in the pair button panel 5, the sample optical recognition system 2 enters the focus mode after the pre-program of initializing the image sensor 1 runs, and uses the image sensor 1 to collect the image of the reference test object , and calculate the image contrast data, the processor 3 converts the image contrast data provided by the image sensor 1 into focus accuracy, provides an input and output device for display output, and prompts the tester to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com