On-line measuring structure for speed and abrasion of traction roller

A traction roller and speed technology, applied in the field of glass plate production, can solve the problems of inability to measure the linear speed and wear of the traction roller, and achieve the effects of high degree of automation, increased service life, improved quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

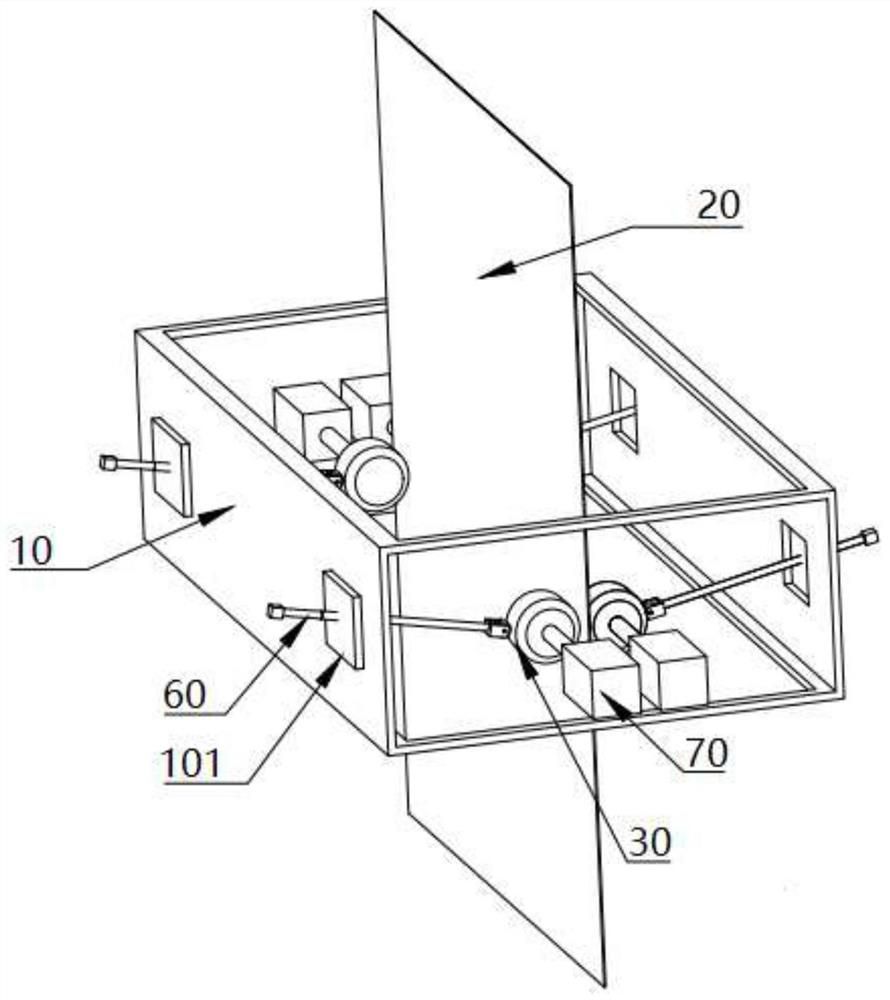

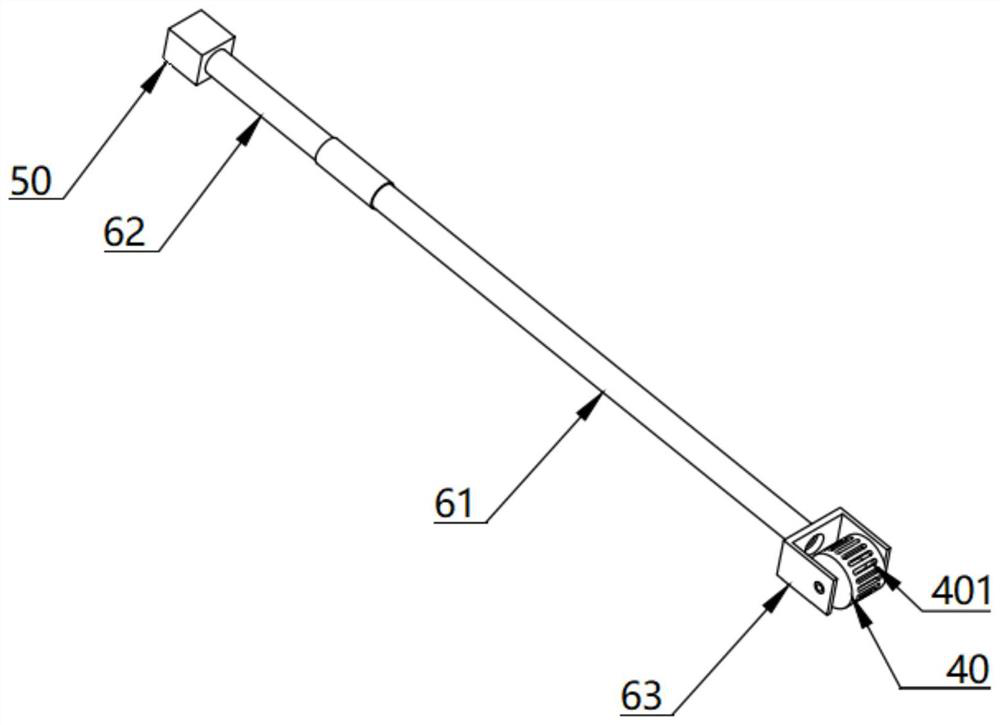

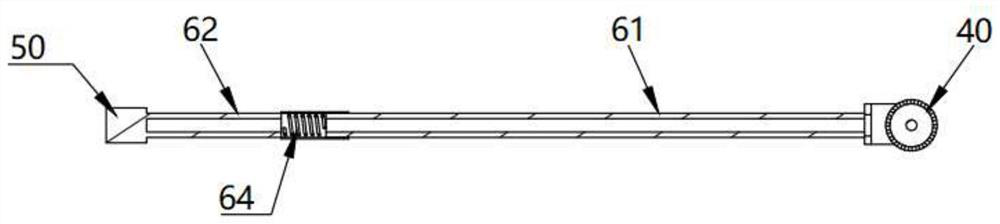

[0026] refer to figure 1 with figure 2 , the preferred embodiment of the present invention provides an on-line measurement structure for the speed and wear of the traction roller, comprising: a furnace body 10, a traction roller 30 for pulling the glass plate 20 to run in the furnace body 10, and a traction roller 30 for online measurement On-line measuring device for speed and wear. The traction roller 30 is rotatably installed on the furnace body 10 and extends into the furnace body 10 . The online measuring device is installed on the furnace body 10, and its detection end extends into the furnace body 10 and is provided with a speed measuring roller 40. The speed measuring roller 40 abuts against the traction roller 30 so as to rotate synchronously under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com