A Measuring Device for Average Corrosion Depth in X-ray Stress Test

A stress test and corrosion depth technology, applied in mechanical depth measurement and other directions, can solve the problems of affecting the accuracy of residual stress on the surface of objects, uneven corrosion pits, large measurement errors, etc., to improve test stability, improve work efficiency, and ensure self-balancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the present invention, the present invention will be further described below with reference to the accompanying drawings and embodiments.

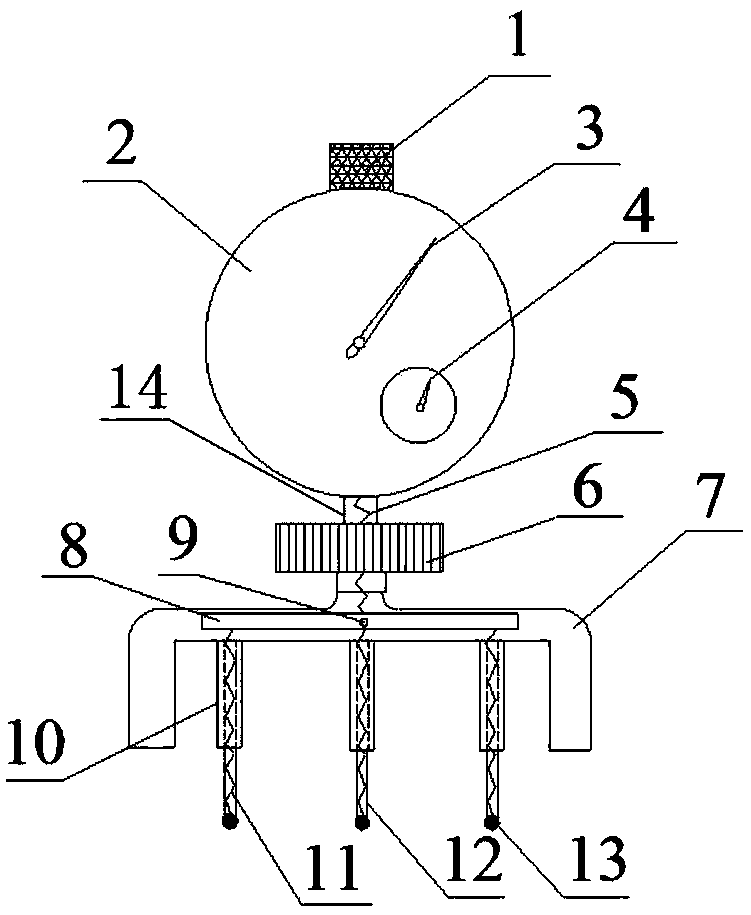

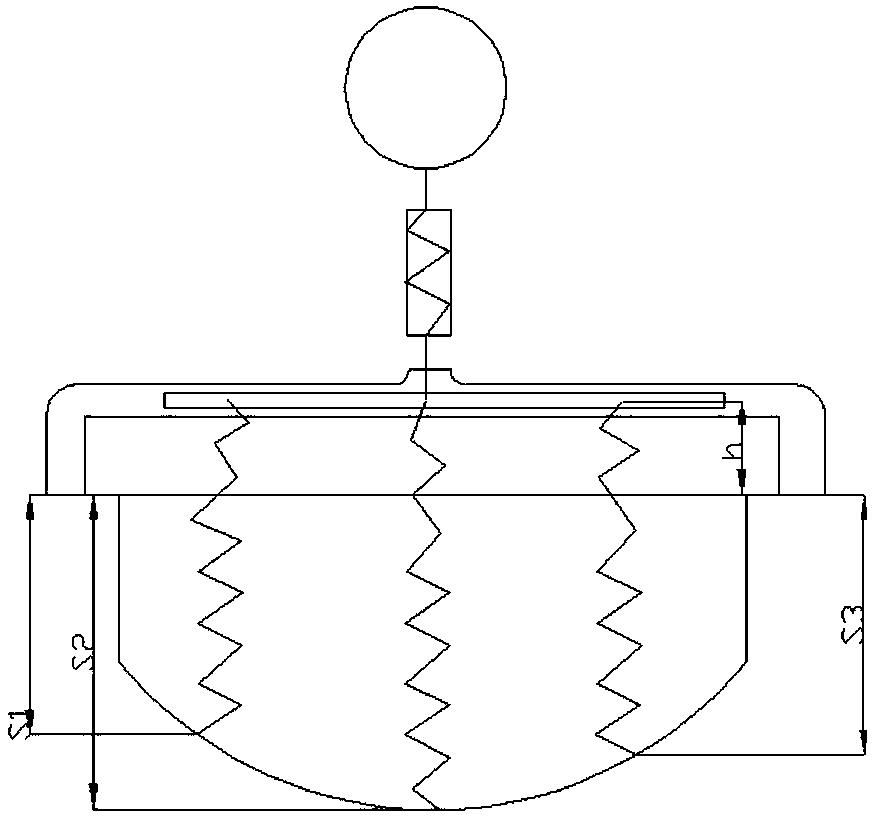

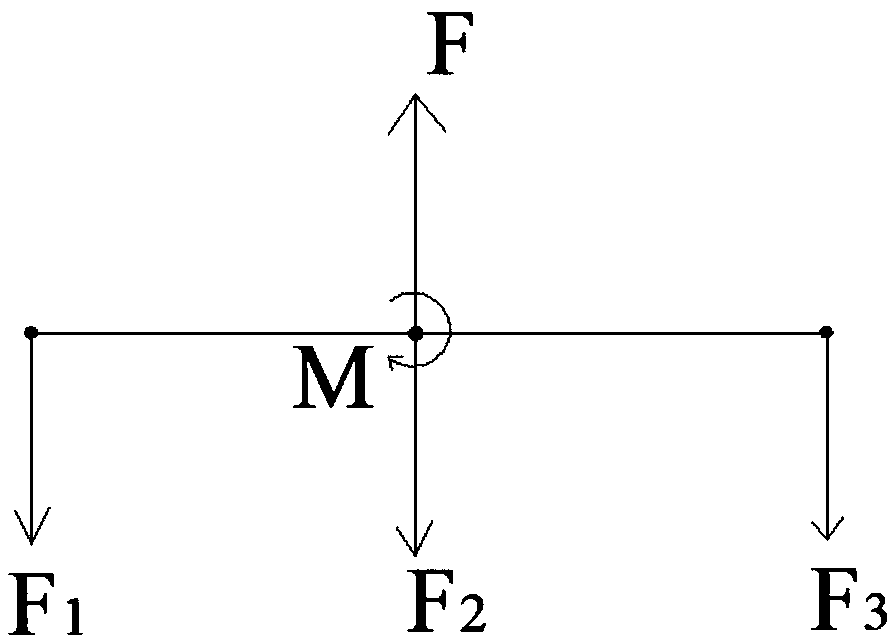

[0015] Such as figure 1 As shown, a measuring device for the average corrosion depth in an X-ray stress test includes a support 7, a support rod 14, and a dial gauge 2. The support is a "U"-shaped hollow bending piece with an opening facing down, which can be A support is formed on the horizontal surface around the corrosion pit of the test object. The support rod is a hollow straight rod. The upper and lower ends of the support rod are respectively connected to the center of the top of the support and the center of the bottom of the dial indicator. A balance plate 8 is horizontally arranged in the cavity on the top of the support. , The center of the balance board is connected to the support through the pin 9; the balance board is provided with a rotating spring, and the bottom surface of the support is ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com