Heat pump-type vermicelli drying equipment

A technology of drying equipment and heat pump, applied in lighting and heating equipment, drying gas arrangement, progressive dryer, etc., which can solve the problems of low energy efficiency, waste of heat, weakening of energy saving advantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

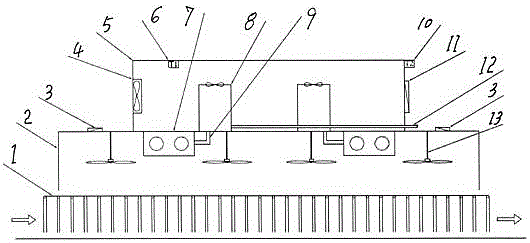

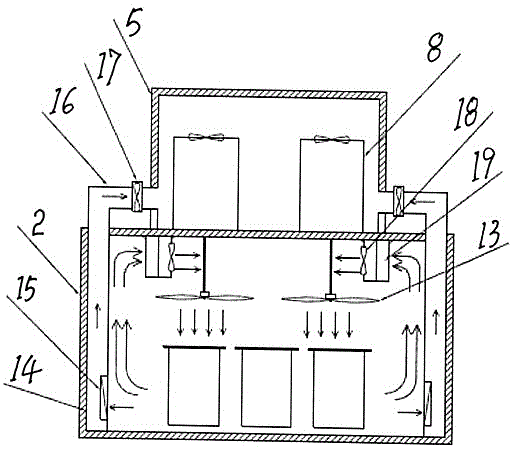

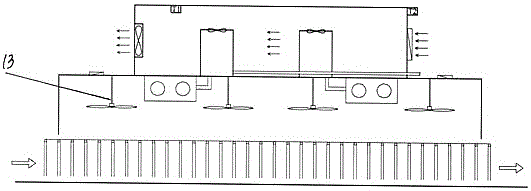

[0009] Embodiments are described in detail in conjunction with the above accompanying drawings, as figure 1 with figure 2 As shown, the drying equipment is mainly composed of a drying chamber 2, a noodle conveying line 1, a hot air blower 7, a dehumidification system 14, a heat pump host 8, a heat pump host room 5, a fresh air damper 3 and a drainage system 12. 2 is located in the lower part of the heat pump host room 5, one end of the drying room is provided with the entrance of the noodle conveying line 1, and the other end is the outlet, and the hot air blower 7 is suspended on the top of the drying room, and the hot air blower 7 includes the condenser of the heat pump 19 and circulation fan 18, the ceiling fan 13 is suspended on the top of the drying room, the dehumidification system 14 is located at the bottom of the drying room, and the dehumidification system is placed at the bottom of the drying room by one end of the dehumidification air pipe, and the other end is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com