Non-wood type paper pulp

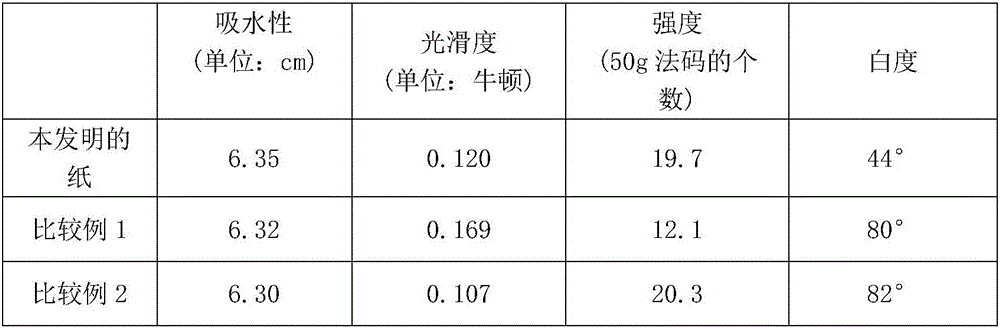

A non-wood and pulp technology, applied in non-woody plant/crop pulp, raw material separation, raw material pretreatment, etc., can solve the problems of stains, dust falling off, excessively white color, etc., to reduce temperature and steam pressure, improve Cellulose content, the effect of improving appearance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

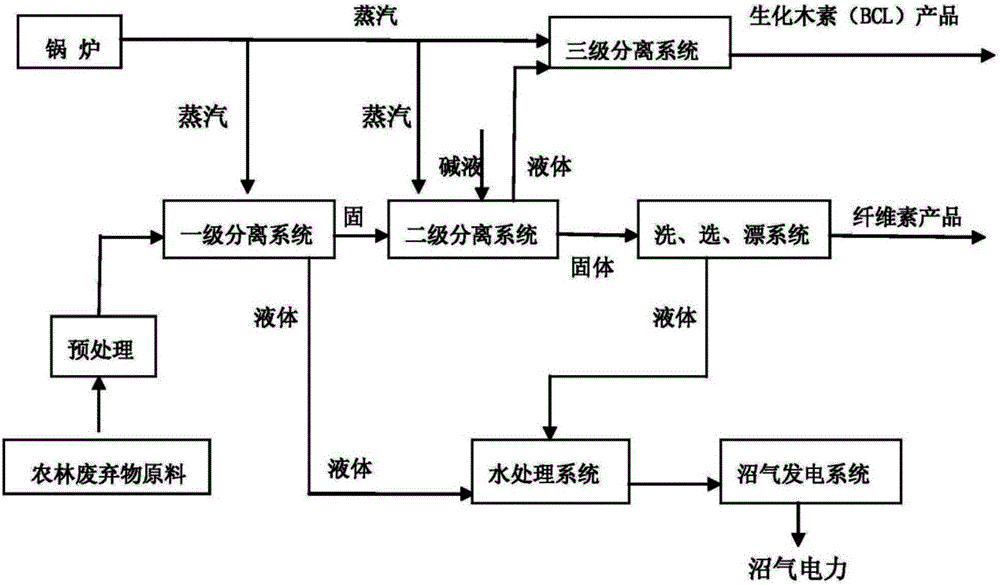

Method used

Image

Examples

Embodiment

[0054] Preparation of non-wood pulp 1:

[0055] 50 tons of wheat straw is used as raw material, and the raw material is pretreated by dust removal, cutting and crushing, and then sent to the cooking tank through the conveying equipment, and steamed with about 2.0MPa steam for about 5 minutes, after cooking, multi-stage cleaning with water is carried out, and passed Precipitation is used for solid-liquid separation, the upper liquid containing hemicellulose is separated, and the solid content of the lower layer after cooking is recovered.

[0056] Next, add 4.5% aqueous sodium hydroxide solution to the obtained cooked solids, cook at about 100°C for about 1 hour, precipitate after cooking, and recover the lower layer of solids, which is the cellulose product (this Invented non-wood pulp 1).

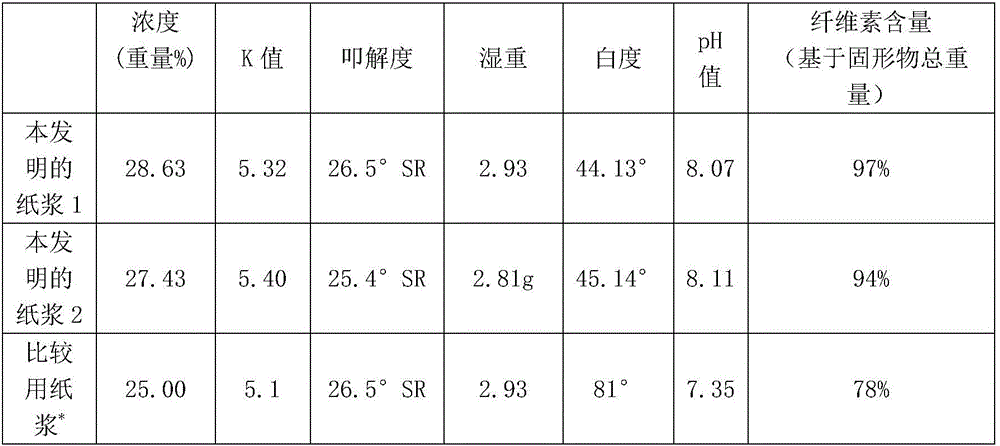

[0057] After analysis, the obtained cellulose product is about 13 tons, and its various indicators are: concentration 28.63%, K value 5.32, percussion degree SR 26.5°, wet weight 2.93g, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com