Lignocellulose raw material dilute acid steam explosion pretreatment method

A technology of lignocellulosic raw materials and lignocellulose, which is applied in the direction of fiber raw material treatment, raw material pretreatment, fiber raw materials, etc., can solve the problems of cumbersome operation, high cost, and inability to use slag fermentation, etc., so as to improve acidolysis efficiency and improve Effects of enzymatic hydrolysis and fermentability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

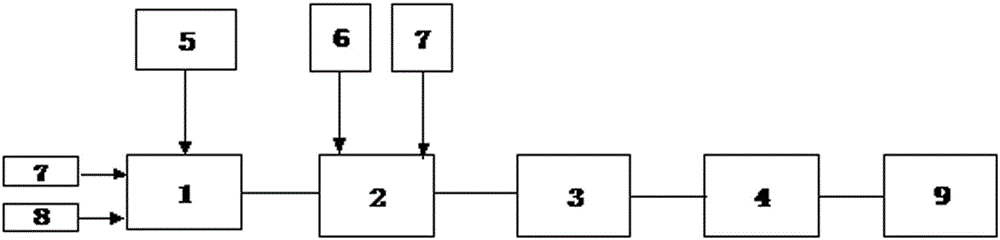

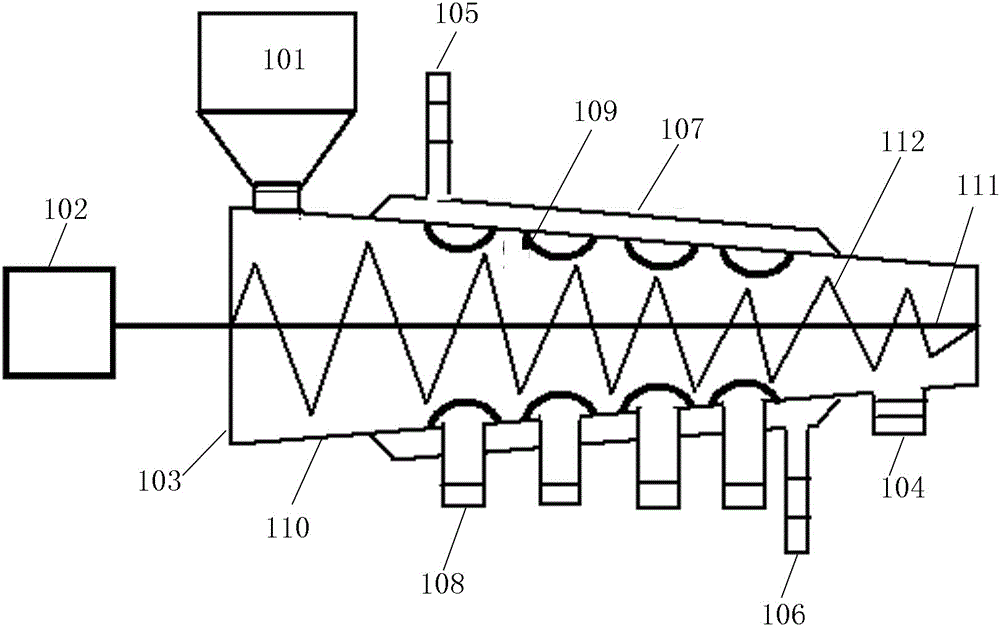

[0035] Using the present invention figure 1 The process flow shown. An inhibitor eluent was prepared to elute the lignocellulose raw material, and the inhibitor eluent included dilute sulfuric acid at a concentration of 1wt%, 0.5wt% NaCl, 0.01wt% SDS and 0.2wt% ammonium oxalate. The prepared inhibitor eluent was preheated to 90°C in a storage tank. Turn on the screw motor of the impregnation detoxification feeder and digester, start the belt conveying system, and the heated inhibitor eluent is continuously added to the impregnation detoxification feeder at the same time as the liquid-solid ratio of 5:1 through the conveying pump. in the hopper of the machine. By adjusting the frequency of the dipping detoxification feeder and the screw motor of the digester, the residence time of corn stalks in the dipping detoxification feeder was 6 minutes, and the residence time in the digester was 8 minutes. The temperature control in the immersion feeder was 120°C, and the temperature ...

Embodiment 2

[0038] Using the same conditions as in Example 1, the difference is that: the inhibitor acid eluent includes a concentration of 0.5wt% dilute sulfuric acid, 1.0wt% NaCl, 0.05wt% SDS and 0.6wt% ammonium oxalate, The residence time of the corn stalk raw material in the dipping detoxification feeder is 8 minutes; the second difference is that the concentration of sulfuric acid in the digester is 1.5%, and the temperature of the digester is controlled at 190°C. The dry matter concentration of the pretreated corn stalks was 31.5%, the proportion of insoluble dry matter was 66.9%, the cellulose content in the dry matter was 38.3%, and the hemifiber content was 8.8%. The concentration of xylose in the extruded liquid was 4.9%, the concentration of glucose was 0.6%, the concentration of xylooligosaccharide was 0.4%, the concentration of oligoglucose was 0.2%, the concentration of acetic acid was 0.4%, and the concentration of total phenol was 39.2mg / L. The enzymatic hydrolysis and fer...

Embodiment 3

[0045] The inventive method comprises the steps:

[0046] Step 1, crushing: crushing the lignocellulosic raw material corn stalks into 0.1mm particles;

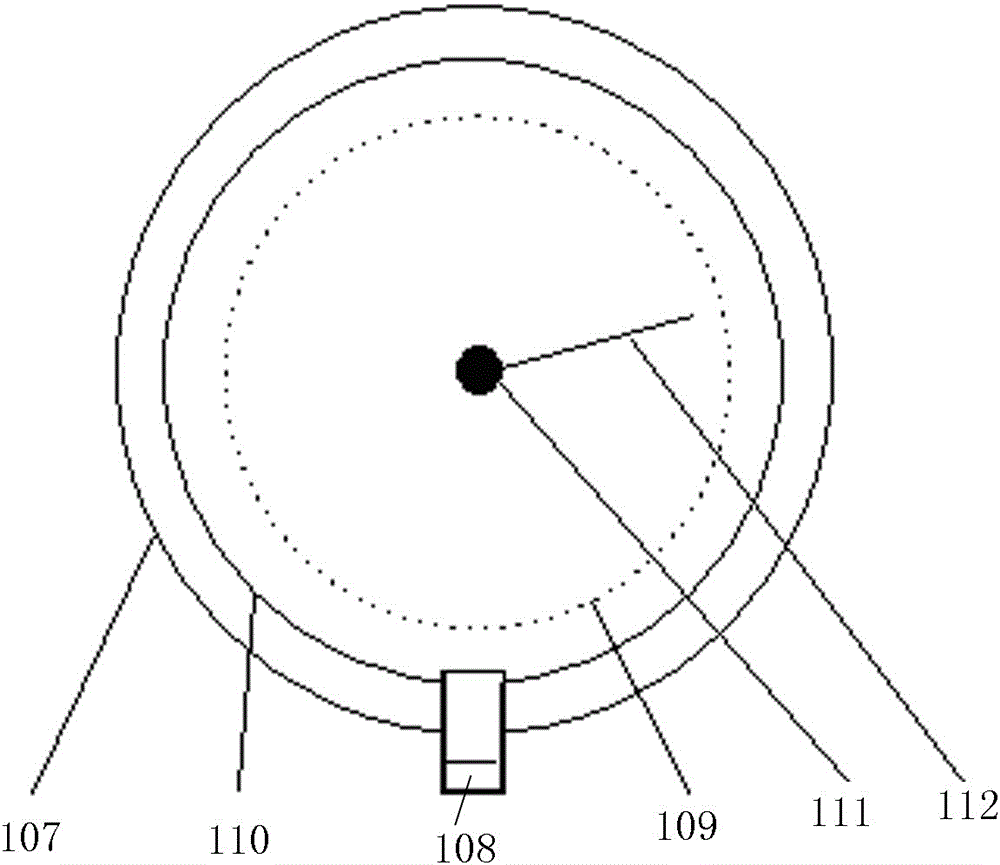

[0047] Step 2, impregnation, detoxification and feeding: prepare the inhibitor eluent and place it in the inhibitor eluent storage tank, and heat it to 60°C in the storage tank, the heated inhibitor eluent and the crushed wood The fiber raw material is continuously added to the hopper of the dipping detoxification feeder at a mass ratio of 10:1, and the inhibitor eluent and lignocellulosic raw material added to the hopper of the dipping detoxification feeder fall freely from the hopper to the conical screw device In the conical screw device, the temperature of the liquid-solid mixed phase in the screw sleeve is controlled by passing steam into the interlayer to 105°C, the residence time is 20min, and the thrust and Kneading, dipping, detoxification, extrusion and dehydration are realized under the resistance of the annular m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com