A kind of chemical copper plating agent and preparation method thereof

A technology of electroless copper plating and copper sulfate, applied in liquid chemical plating, metal material coating process, coating and other directions, it can solve problems such as physical injury, non-compliance, and high toxicity of employees, and achieve adhesion and resistance to humidity and heat. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] ① Add 30% deionized water to the container;

[0019] ② When stirring, add 0.04% EDTA-2Na (disodium ethylenediaminetetraacetic acid) according to the proportion, and stir for 25-30 minutes;

[0020] ③ While stirring, add 0.007% copper sulfate according to the ratio, and continue stirring for 25-30 minutes;

[0021] ④ When stirring, add 0.007% sodium hydroxide according to the proportion, and continue stirring for 25-30 minutes;

[0022] ⑤ When stirring, add 0.005% EDTP (tetrahydroxypropylethylenediamine) according to the proportion, and continue stirring for 25-30 minutes;

[0023] ⑥ When stirring, add 0.004% formaldehyde, 0.005% methanol, 0.05% adipic acid and 0.01% succinic acid according to the proportion, and continue stirring for 25-30 minutes;

[0024] ⑦Add water to the required amount, and stir well after completion.

Embodiment 2-5

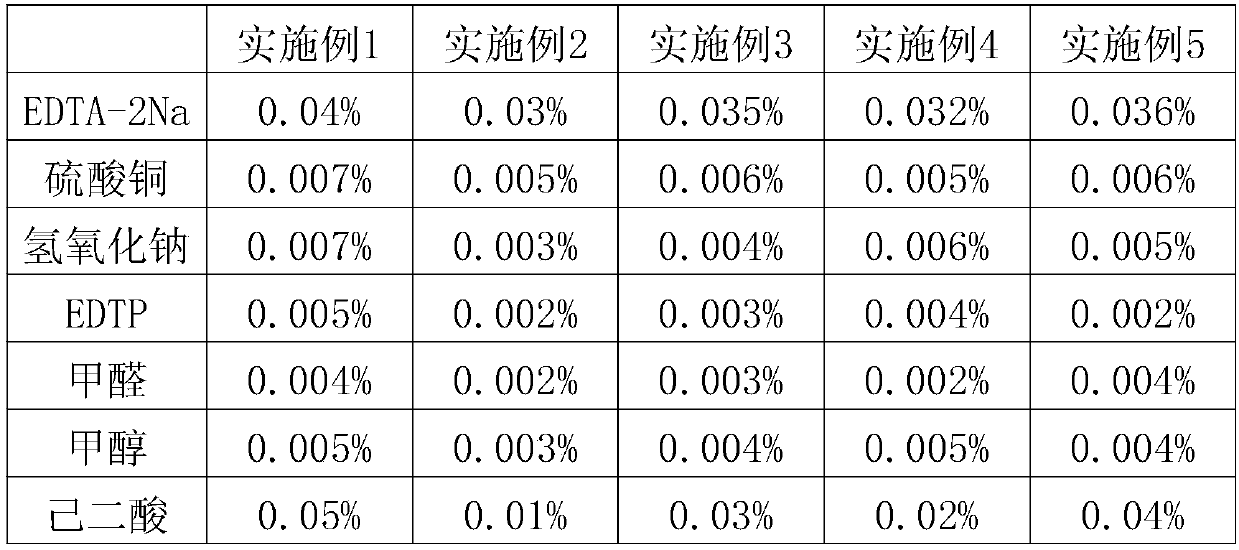

[0026] Repeat the method of Experimental Example 1 by the content of each component specified in Table 1 to obtain different proportioning chemical copper plating agents (omitting deionized water), and the gained chemical copper plating agents are tested according to RoHS requirements.

[0027] Table 1:

[0028]

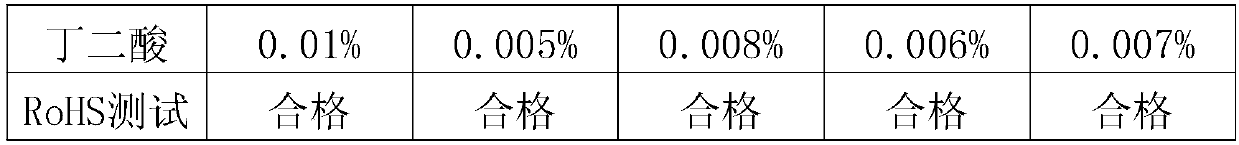

[0029]

[0030] The whole product to be plated is immersed in the middle of the electroless copper plating agent that embodiment 1-5 makes 30min, takes out and dries, and adopts CuCl 2 The system copper plating agent was used as a control example for testing.

[0031] The detection method is:

[0032] ①Adhesion test: Repeat the 3M tensile test of Baige 3 times to observe whether the coating has fallen off;

[0033] ②Double 85 test: place it in an environment with a temperature of 85°C and a humidity of 85%, and observe when the coating changes.

[0034] Table 2:

[0035]

[0036] As can be seen from Table 2, compared to CuCl 2 System copper plati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com