Overflow tilting novel microalgae culture system

A culture system and technology for microalgae cultivation, which is applied in the field of overflow tilting new microalgae cultivation system and microalgae cultivation, can solve the problems of increasing the light-receiving surface area, making full use of the space light level, low-cost construction and large-scale application , It is difficult to meet the problems of low cost, high density and high efficiency culture of microalgae, and achieve the effect of low cost production and operation cost, simple structure and increased light receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

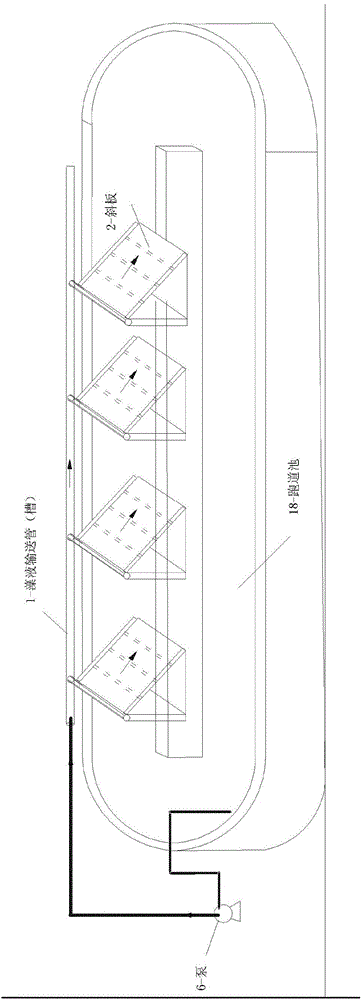

[0096] The invention designs a new culture system for microalgae culture. It should be understood that the "system" or "cultivation system" used in the present invention refers to a product, that is, a device or equipment. The new type of microalgae culture system takes the spatial three-dimensional component unit-inclined sloping plate as the main body, and transports the algae liquid in the storage tank to the liquid transportation method such as pump or air-lift or other algae liquid transportation methods. In the overflow tank at the top of the inclined plate, the algae liquid overflows from the overflow tank along the inclined plate into the algae accumulation tank by gravity, and the algae liquid flows back to the storage tank through the algae liquid collection tank.

[0097] When the algae fluid flows along the inclined plate, the sunlight irradiated on the inclined plate can be fully utilized, and the algae cells can fully receive the light. In terms of the light-receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com