Recycled concrete with highly effective damping property

A recycled concrete and damping technology, which is applied in the field of building materials, can solve the problems of poor bonding ability of fibers and cement, unfavorable social development, and affecting people's lives, etc., to improve strength and toughness, improve impregnation and permeability, and increase specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing recycled concrete with high-efficiency damping performance, comprising the following steps:

[0030] The first step: screening of fine aggregate

[0031] According to the requirements of the standard JGJ52-2006 on the gradation of fine aggregate particles, the fine aggregate that meets the requirements of concrete preparation is screened out.

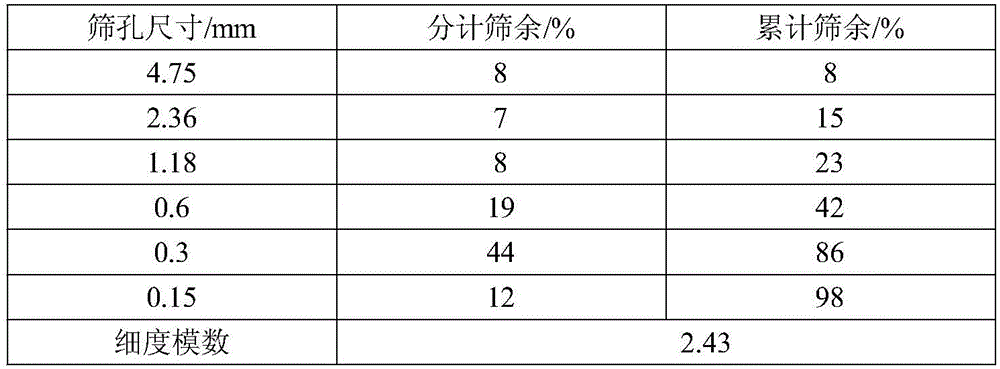

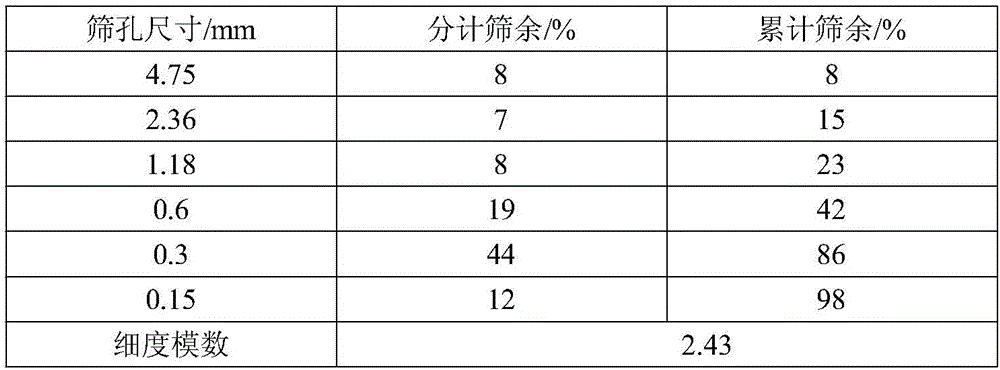

[0032]

[0033] Table 1 Results of fine aggregate particle grading test

[0034] The analysis results are shown in Table 1. It can be seen that the particle size distribution of the fine aggregate is good, so the fine aggregate is used to prepare recycled concrete.

[0035] Step 2: Pretreatment of Coarse Aggregate

[0036] The gravel is used as the coarse aggregate, and the coarse aggregate is mechanically crushed, impurity removed, cleaned, dried, and screened according to the requirements of the "General Concrete Sand and Stone Quality and Testing Method Standard" for coarse aggregate to ensure Coar...

Embodiment 2

[0049] A method for preparing recycled concrete with high-efficiency damping performance, comprising the following steps:

[0050] The first step: screening of fine aggregate

[0051] According to the requirements of the standard JGJ52-2006 on the gradation of fine aggregate particles, the fine aggregate that meets the requirements of concrete preparation is screened out.

[0052]

[0053] Table 1 Results of fine aggregate particle grading test

[0054] The analysis results are shown in Table 1. It can be seen that the particle size distribution of the fine aggregate is good, so the fine aggregate is used to prepare recycled concrete.

[0055] Step 2: Pretreatment of Coarse Aggregate

[0056] Mix gravel and waste concrete in any ratio to form coarse aggregate, and then mechanically crush and remove impurities according to the requirements for coarse aggregate in the Standards for the Quality and Testing Methods of Sand and Stone for Ordinary Concrete , cleaning, drying, ...

Embodiment 3

[0069] A method for preparing recycled concrete with high-efficiency damping performance, comprising the following steps:

[0070] The first step: screening of fine aggregate

[0071] According to the requirements of the standard JGJ52-2006 on the gradation of fine aggregate particles, the fine aggregate that meets the requirements of concrete preparation is screened out.

[0072]

[0073] Table 1 Results of fine aggregate particle grading test

[0074] The analysis results are shown in Table 1. It can be seen that the particle size distribution of the fine aggregate is good, so the fine aggregate is used to prepare recycled concrete.

[0075] Step 2: Pretreatment of Coarse Aggregate

[0076] Mix gravel and waste concrete in any ratio to form coarse aggregate, and then mechanically crush and remove impurities according to the requirements for coarse aggregate in the Standards for the Quality and Testing Methods of Sand and Stone for Ordinary Concrete , cleaning, drying, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com