Gravity refueling type multifunctional integrated aviation oil filling device

A filling device and multi-functional technology, which is applied in the direction of liquid conveying device, etc., can solve the problem that fuel trucks are not suitable for airports with small and medium flow, and achieve the effects of improving convenience, compact structure and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

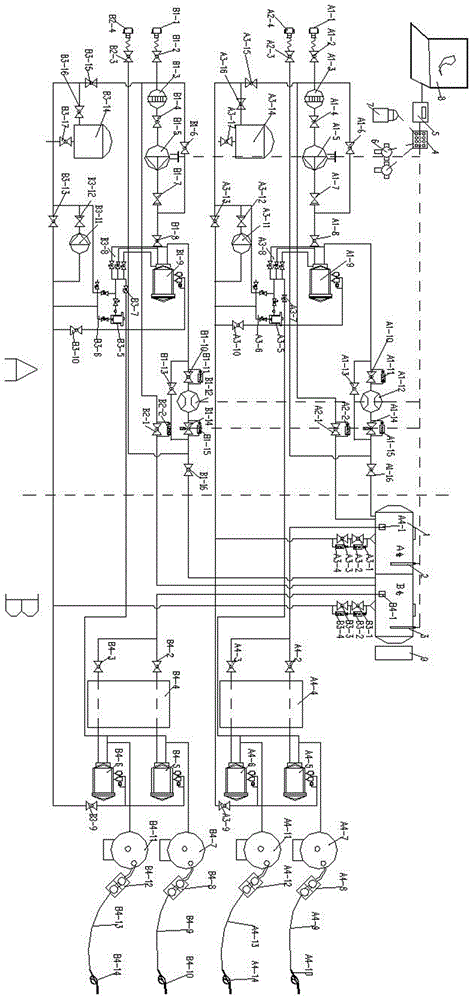

Image

Examples

Embodiment 1

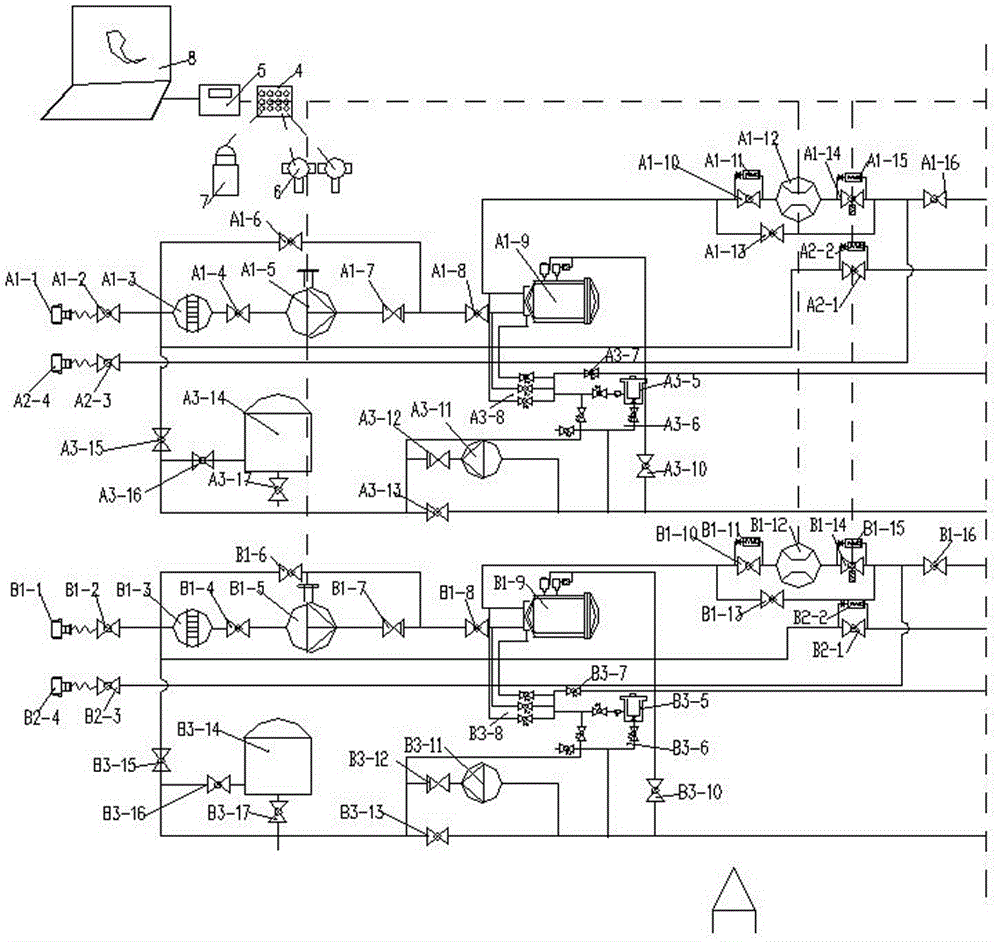

[0074] Implementation of embodiment one oil collection function:

[0075] 1. 1A warehouse oil collection (medium 1)

[0076] The first connection joint A1-1 is connected to the oil outlet of the tanker, the valves A1-2, A1-4, A1-8, A1-10, A1-14, A1-16 are opened, and the valves A2-1, A2-3, A3 -15 off,

[0077] Start the pump A1-5 to collect oil, and adjust the opening of the valve A1-6 to adjust the flow of the pump.

[0078] The medium 1 is transported by the pump A1-5, filtered and separated by the first filter separator A1-9, measured by the flow meter A1-12, and finally enters the storage tank A warehouse. It is not necessary to use a flow meter in the process of collecting oil in A warehouse.

[0079] 1. 2B warehouse oil collection (medium 2)

[0080] The first connection joint B1-1 is connected to the oil outlet of the tanker, the valves B1-2, B1-4, B1-8, B1-10, B1-14, B1-16 are opened, and the valves B2-1, B2-3, B3 -15 off,

[0081] Start the pump B1-5 to collect ...

Embodiment 2

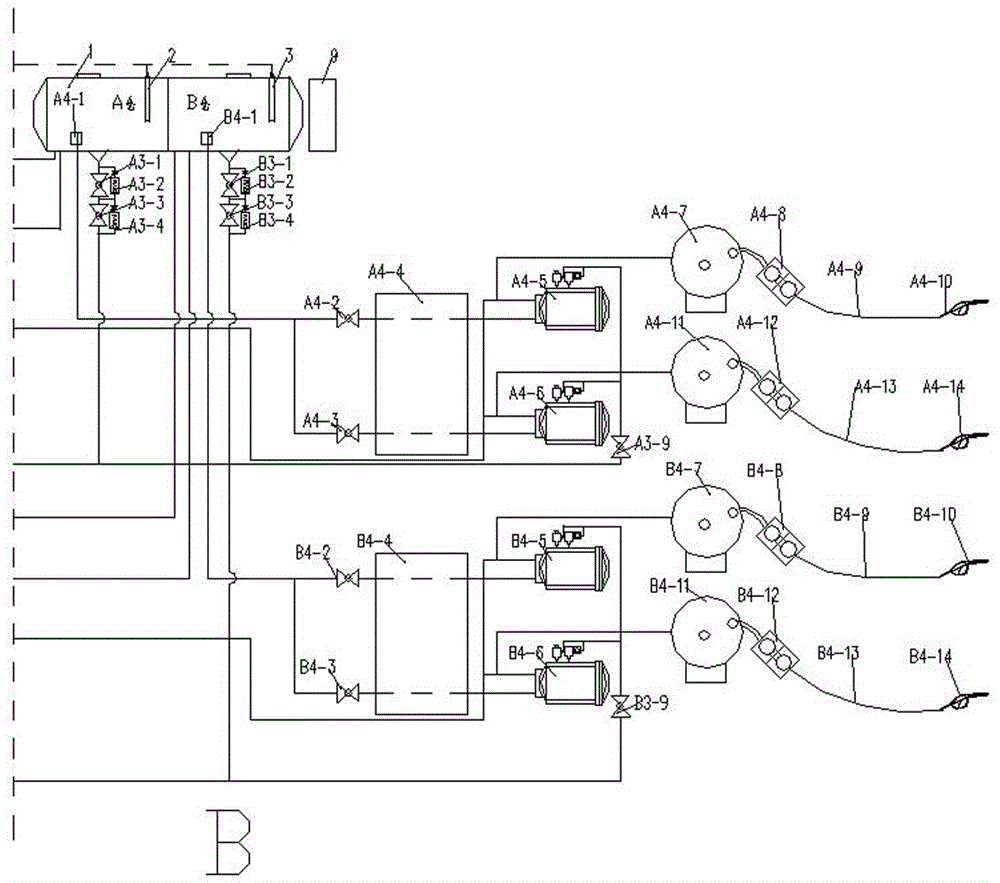

[0083] The realization of embodiment two refueling function:

[0084] 2.1 Refueling in tank A (medium 1)

[0085] The fueling gun A4-10 is connected with the oil receiving port of the oil receiving equipment, and the valve A4-2 is opened.

[0086] Dispenser A4-4 controls start-up pump A4-1 to transport medium 1, medium 1 is transported by fuel pump A4-1, is metered and displayed by dispenser A4-4, and is filtered and separated by second filter separator A4-5. Then it enters the oil receiving equipment through the refueling reel A4-7, the pull-off valve A4-8, the refueling hose A4-9, and the refueling gun A4-10. After the refueling is completed, the refueling gun is closed, and the signal is fed back to the refueling machine, and the refueling machine controls the pump A4-1 to stop.

[0087] The fueling gun A4-14 is connected with the oil receiving port of the oil receiving equipment, and the valve A4-3 is opened.

[0088] Dispenser A4-4 controls start-up pump A4-1 to transp...

Embodiment 3

[0097] Implementation of Embodiment Three Stirring Function

[0098] 3. 1A warehouse stirring function (medium 1)

[0099] Valves A3-1, A3-3, A3-13, A3-15, A1-4, A1-8, A1-10, A1-14, A1-16 open, valves A3-9, A3-10, A3-6 (valve group), A3-16, A1-2, A1-13 closed,

[0100]Start the pump A1-5 for medium delivery, and adjust the opening of the valve A1-6 to adjust the flow of the pump.

[0101] Medium 1 comes out of bin A, transported by pump A1-5, filtered and separated by oil collection filter separator A1-9, and measured by flow meter A1-12 (A1-10, A1-14 can also be closed, A1- 13 open, without flow meter A1-12 measurement), into the storage tank A warehouse.

[0102] 3. Stirring function of bin 2B (medium 2)

[0103] Valves B3-1, B3-3, B3-13, B3-15, B1-4, B1-8, B1-10, B1-14, B1-16 open, valves B3-9, B3-10, B3-6 (valve group), B3-16, B1-2, B1-13 closed,

[0104] Start the pump B1-5 for medium delivery, and adjust the opening of the valve B1-6 to adjust the flow of the pump....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com