A wheel hub motor device with high output torque and automobile

An in-wheel motor and high-torque technology, which is used in power units, control devices, transportation and packaging, etc., can solve the problems of small changes in space size, integration, and large size, and achieve simplified vehicle structure and easy technical implementation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

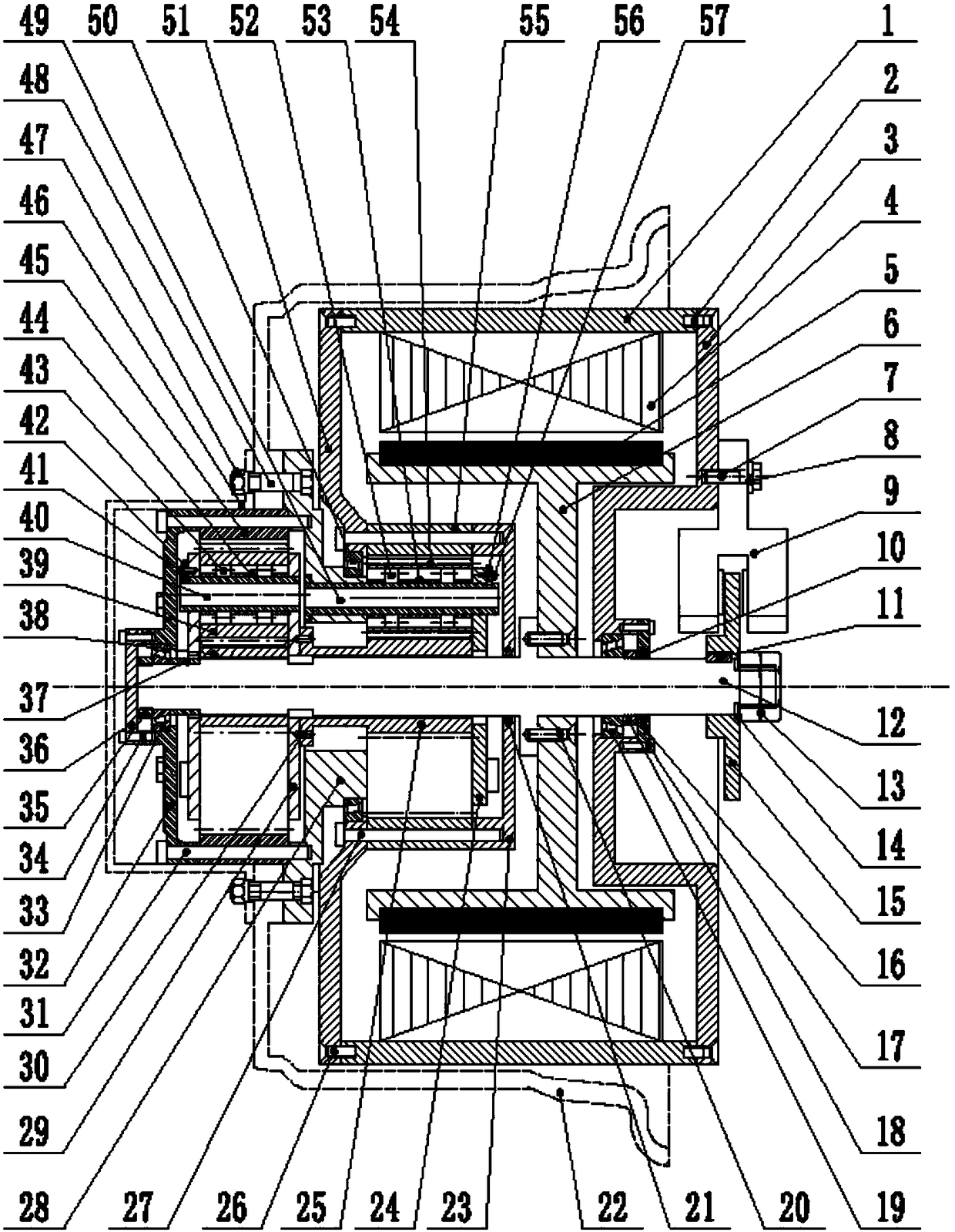

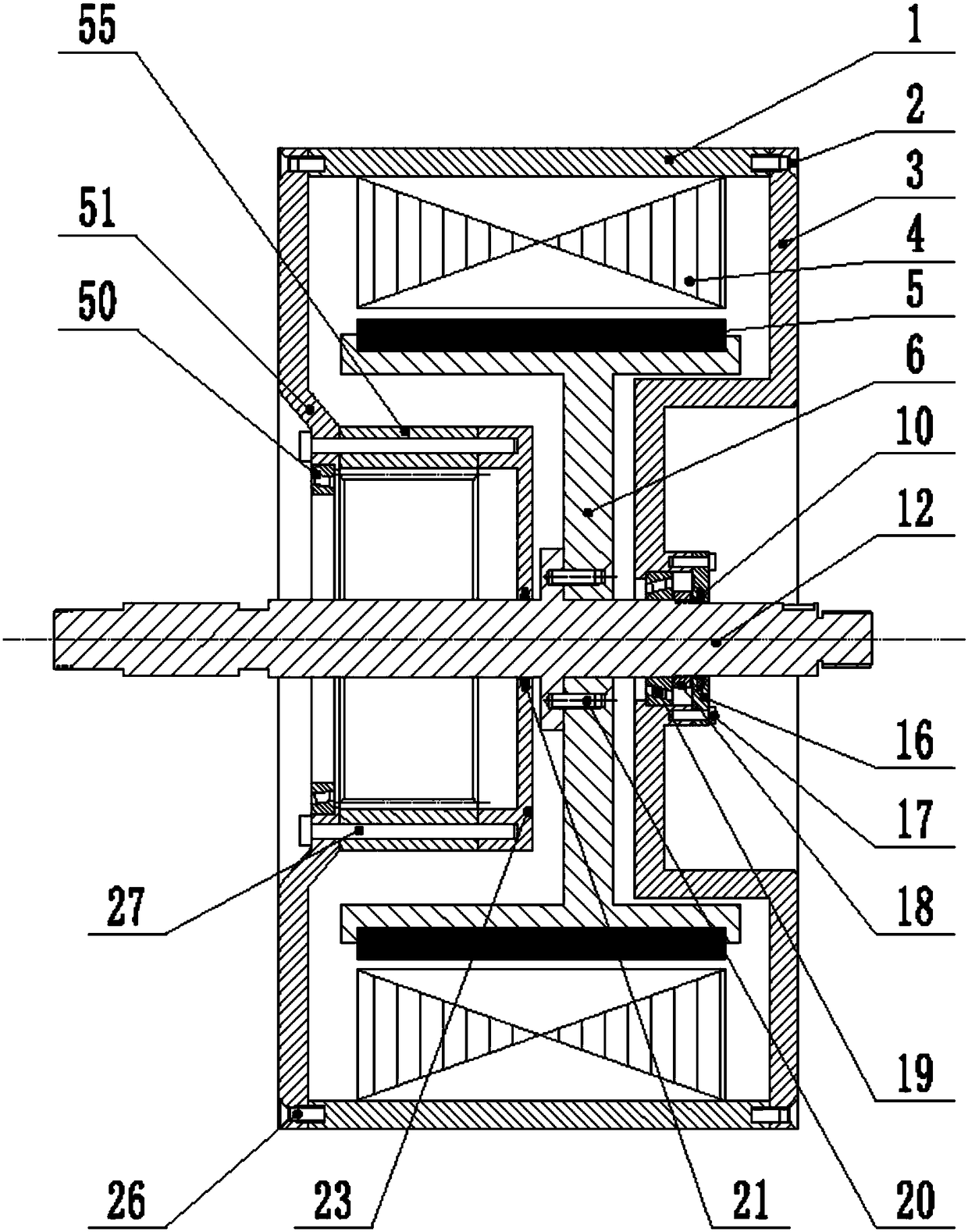

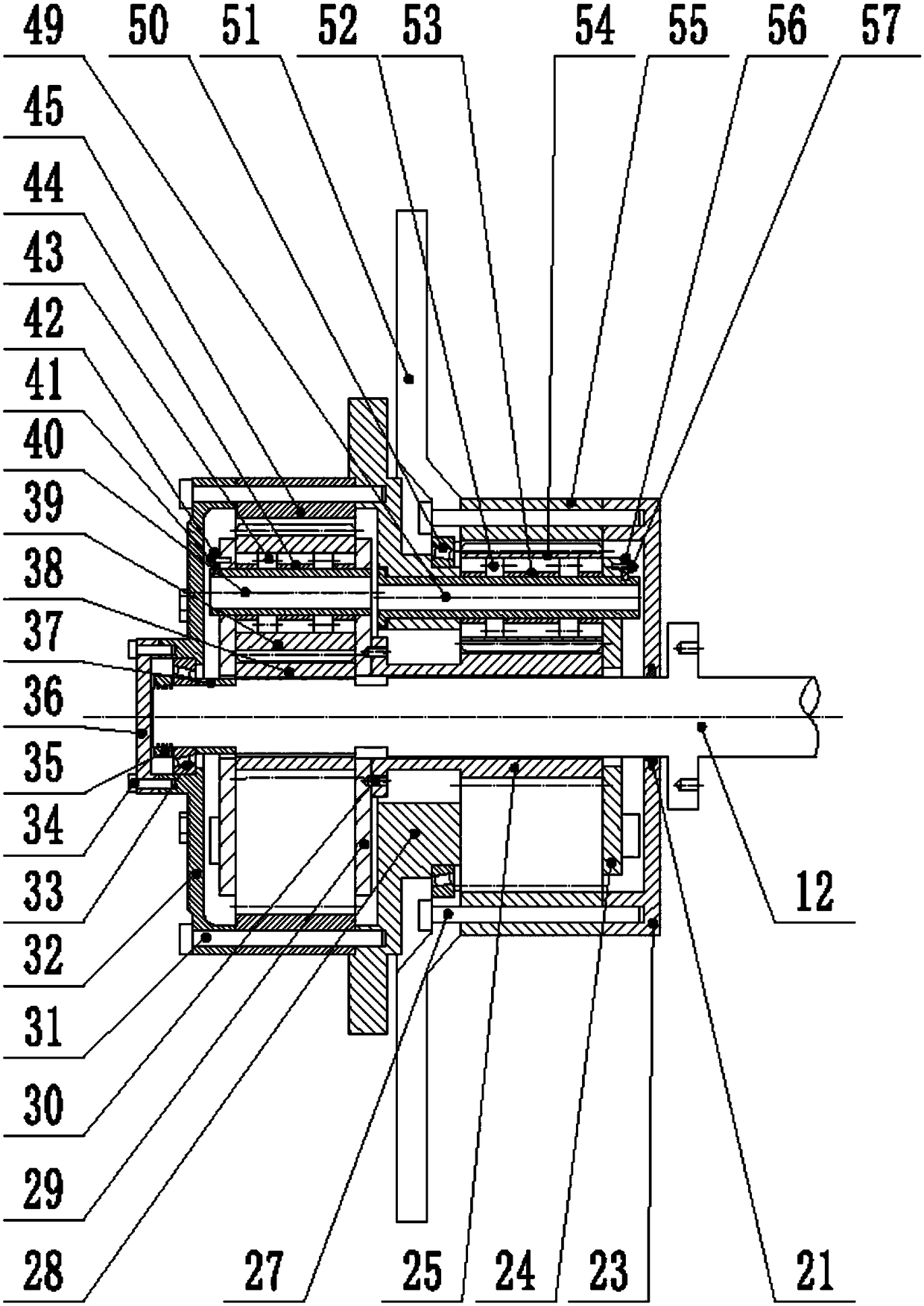

[0065] Attached below figure 1 ~9 further describe the present invention in detail, so that those skilled in the art can implement it according to the text of the description.

[0066] as attached figure 1 Shown is the hub motor assembly structure of the present invention with integrated double-stage reducer, Figure 9a , Figure 9b Shown is the snap ring structure of the planetary wheel shaft according to the present invention, the motor shaft 12 is connected to the first sun gear 38 through a spline, the first planetary wheel 39 is supported on the first planetary wheel shaft 40 through the first planetary wheel bearing 43, the second A planet wheel bearing 43 is positioned through the first planet wheel bearing positioning sleeve 44, the first planet wheel shaft 40 is connected with the first planet carrier 29 through the first planet wheel shaft snap ring 42, and the first planet wheel shaft snap ring 42 is connected with the first planet wheel shaft snap ring 42. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com