Clutch of a single engine washing and sweeping vehicle and its working method

A technology for clutch and vehicle cleaning, applied in the field of clutches, can solve the problems of the clutch being unable to be engaged at high speed, not being able to be combined at high speed, and the volume of the friction clutch being large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

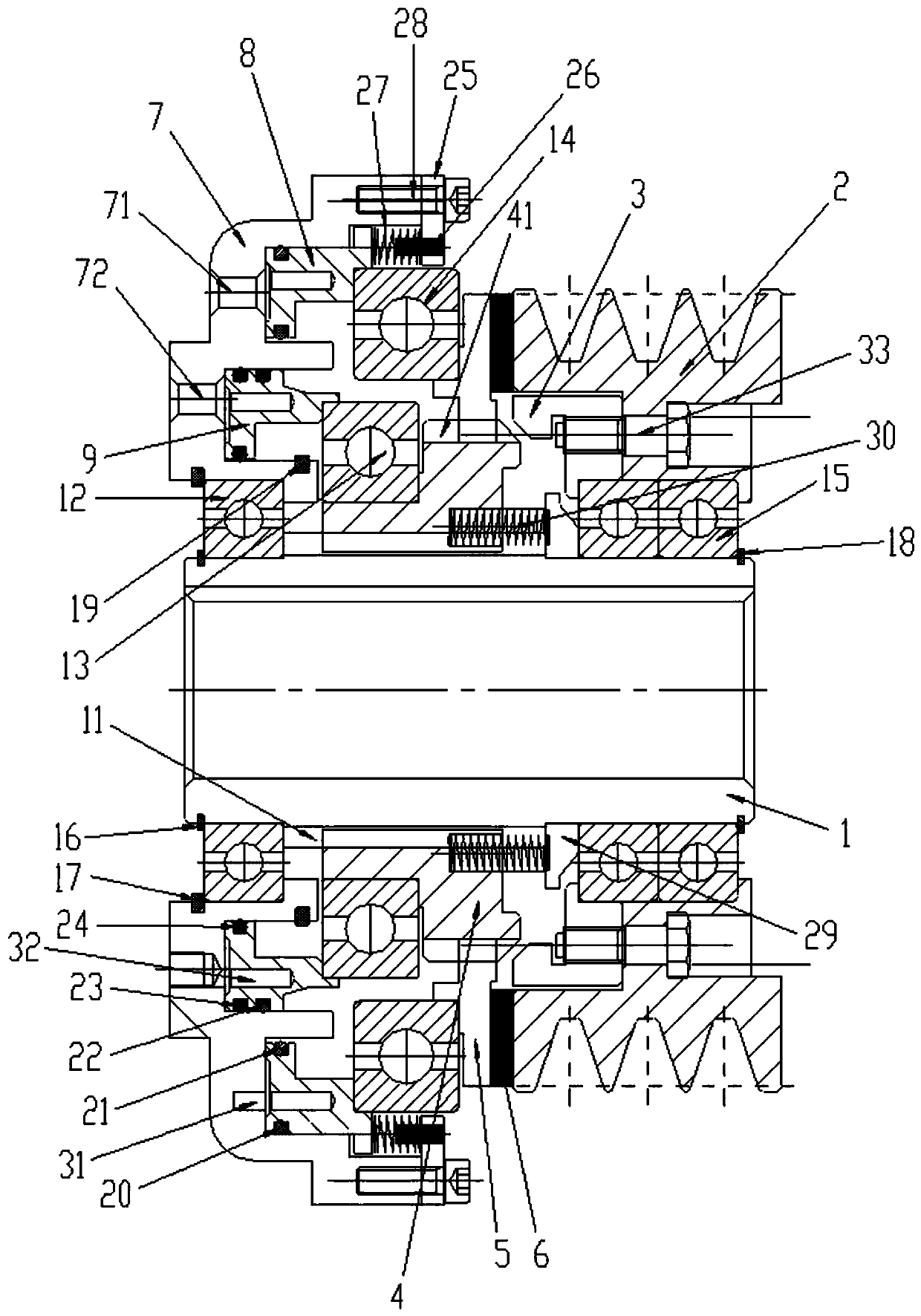

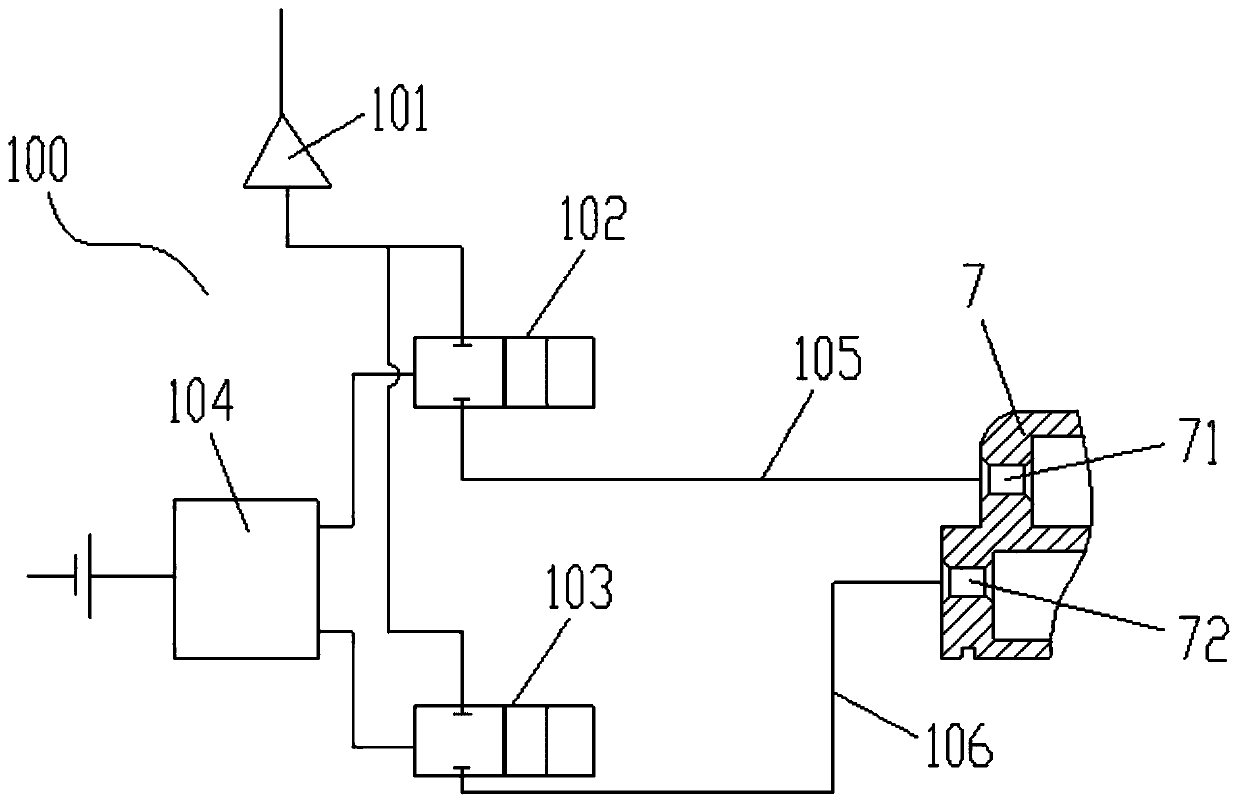

[0026] Such as figure 1 Shown, a kind of clutch of single engine washing and sweeping car, comprises:

[0027] A shaft sleeve 1 for connecting the power input end;

[0028] A pulley 2 is used to connect the power output end; the pulley 2 is rotatably mounted on the outer periphery of the bushing 1, and the rear side of the pulley 2 is provided with an inner ring gear 3;

[0029] A transmission disc 4 is used to transmit the rotational movement of the shaft sleeve 1 to the pulley 2; The shaft sleeve 1 rotates synchronously, and the outer periphery of the front part of the transmission disc 4 is provided with an external tooth 41 capable of engaging and separating from the inner ring gear 3;

[0030] A pressure plate 5 is used to transmit the rotational mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com