Single-head swing type striking-off machine

A head swinging and scraping machine technology, applied in the field of single-head swinging scraping machine, can solve the problems of poor heat resistance, increased production cost, easy carbonization, etc., to increase the heat dissipation area, increase the service life, and improve the sharpness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

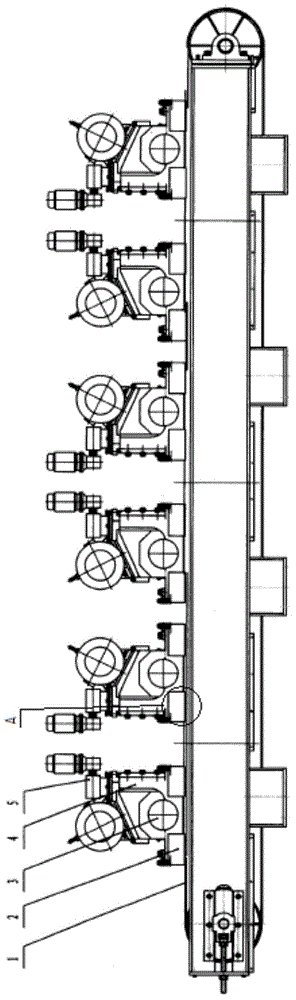

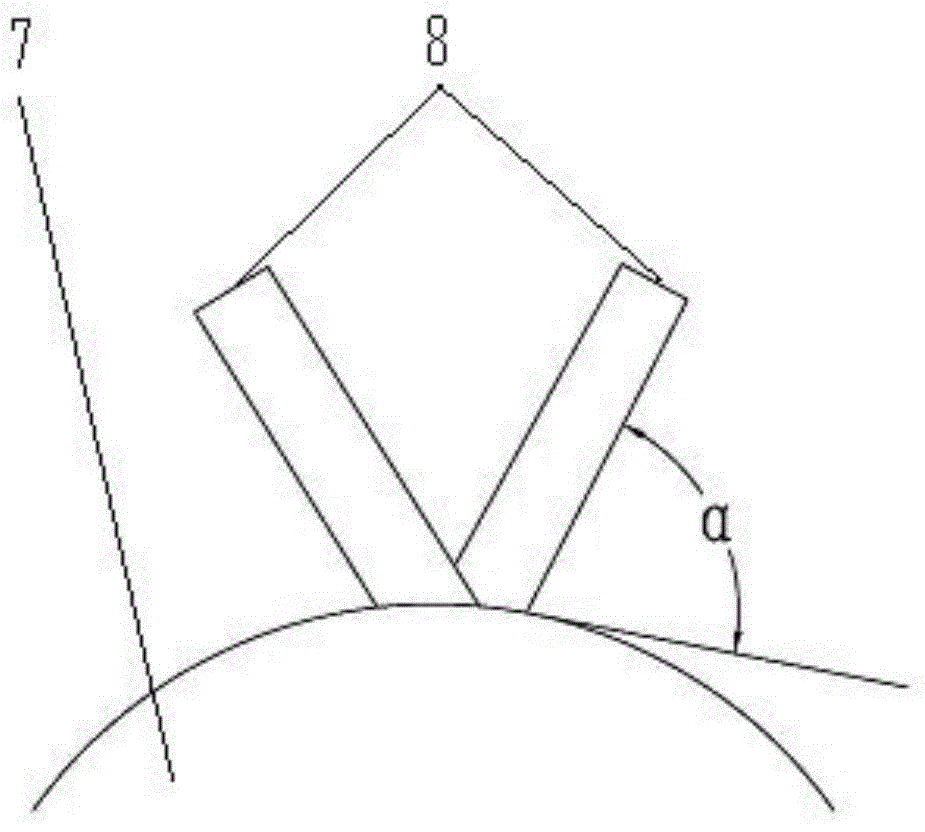

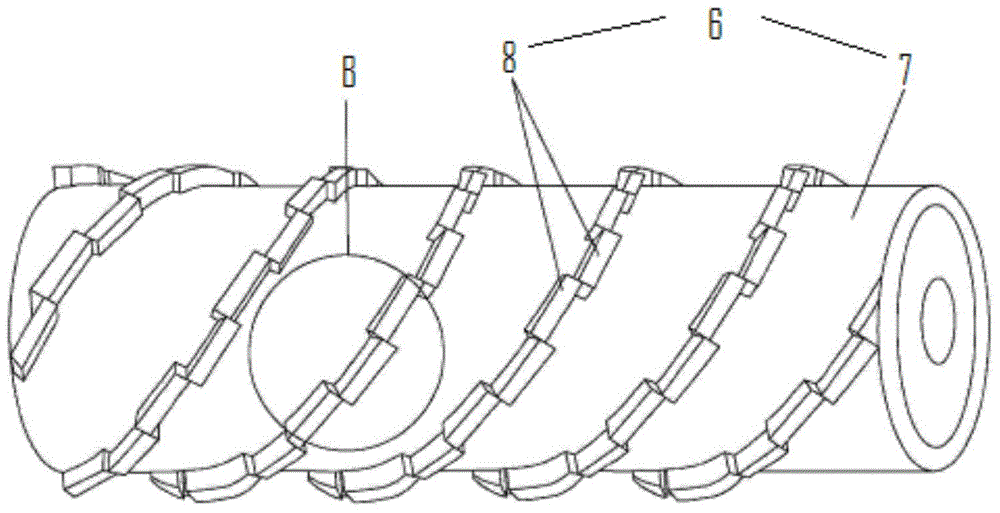

[0024] Below in conjunction with accompanying drawing, the present invention is described in detail, as figure 1 As shown, the prior art provides a single-head swing type scraper, including a frame, a transmission device with a conveyor belt 1, a hob frame with a diamond hob 6 built in, a swing device and six independent Single-head swing bracket assembly, each single-head swing bracket assembly is composed of single-head swing bracket 4 and sliding device 2, each single-head swing bracket assembly is not connected with other single-head swing brackets; a single independent Single-head swing bracket assembly, the bracket is equipped with a scraper frame, the scraper 3 in the scraper frame is driven by a motor to rotate at high speed, and the scraper frame can be lifted up and down and horizontally adjusted by the adjustment device 5 installed on the bracket; single-head swing The bracket assembly is composed of a single-head swing bracket and a sliding device. It is driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com