Novel plank tenon processing method and related special equipment

A processing method and technology of special equipment, applied in the direction of wood processing appliances, dovetail processing, manufacturing tools, etc., can solve the problems of easy occurrence of defects, poor work efficiency and low accuracy of wood cutting, and prolong the service life and accuracy. , Avoid equipment repair and maintenance, and ensure the effect of service life and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] In order to understand the present invention more easily, the implementation manners of the present invention will be described in detail below with specific examples.

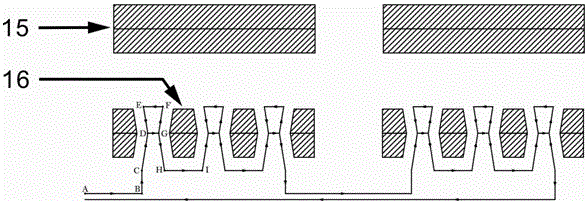

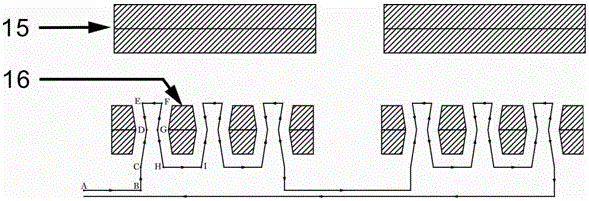

[0023] like figure 1 , figure 2 As shown, a novel tenon processing method of wood planks according to the present invention mainly includes superposition of planks and processing together, cutting tool cutting track, and is characterized in that:

[0024] Its specific embodiment one is as follows: first, place the plank 15 superimposed on the workbench, and then start the tool, from the starting point A to the tangent point B, from the tangent point B to the tangent point C, from the tangent point C to the tangent point D, from the tangent point D to point G, from point G to point F, from point F to point E, from point E to point D, from point D to point G, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com