A finishing tappet hole honing tool and processing method

A processing method and tappet hole technology, which are applied in the field of tools for finishing tappet holes, can solve the problems that the tool rigidity and structural strength are difficult to meet, the coaxiality cannot meet the requirements, and the center position cannot be guaranteed, and achieve automatic The effect of adjusting the knife, easy to operate, and preventing eccentric grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

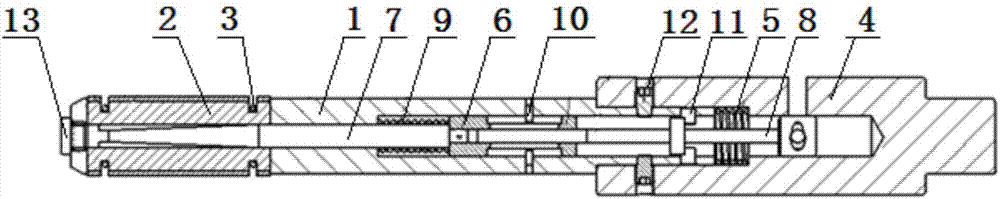

[0030] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

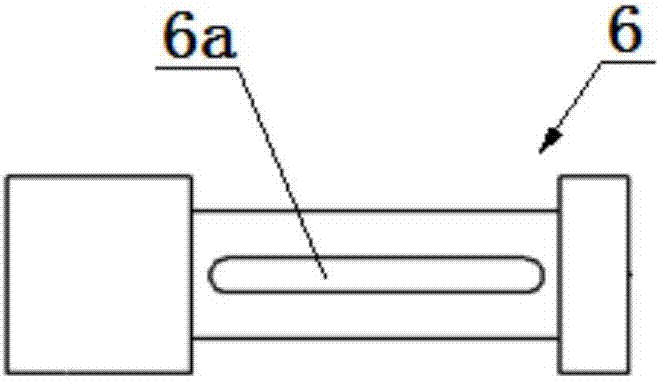

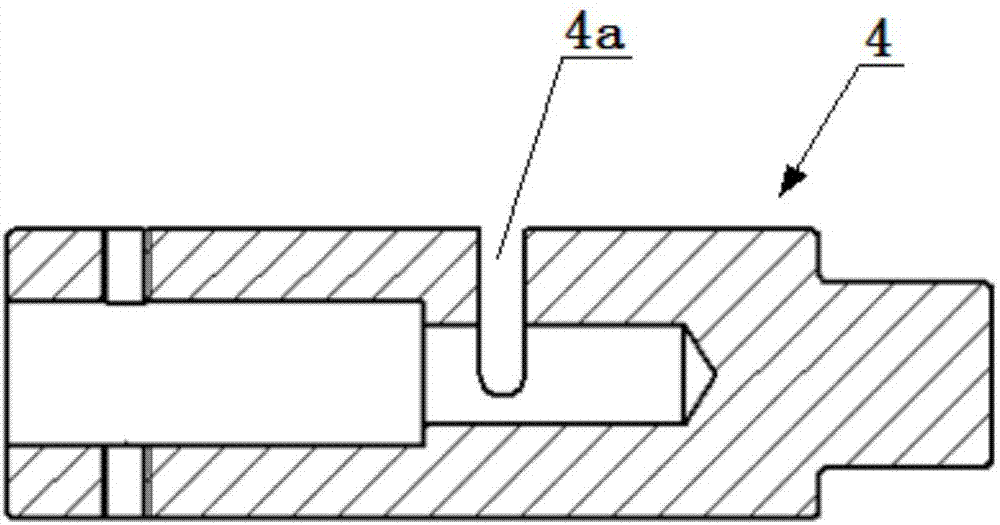

[0031] refer to Figure 1-4 As shown, a honing tool for finishing tappet holes of the present invention includes a honing rod 1 of hollow structure, the inner cavity of the honing rod 1 is a stepped structure, and correspondingly, the outer surface of the honing rod 1 is also a stepped structure. One end of the honing rod 1 is provided with a blade mounting seat, and a chamfer suitable for the tappet hole is provided at the end, which is beneficial to correct the coaxiality of the tool and the tappet hole. Grooves are provided at both ends of the mounting seat. One end of the honing rod 1 is provided with a honing base 2 corresponding to the blade mounting seat and welded with a honing rod. The diameter of the honing rod can be divided into five equal parts starting from the cutter head, which are D1, D2, D3, D4, D5, its size relationship i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com