Graphene-nanometer titanium dioxide composite fabric finishing catalyst and preparation method thereof

A technology of nano-titanium dioxide and graphene, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as difficult industrial production, low production efficiency, and long preparation time, and achieve easy operation, The effect of low preparation cost and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Fabric pretreatment process: at room temperature and under stirring conditions, firstly immerse the fabric in an aqueous solution containing 2.0g / L sodium carbonate and 2.0g / L soap powder, and stir at 95°C for 30 minutes, take it out, and then use Wash the fabric 5 times with distilled water, and finally dry it;

[0024] 2. Preparation of graphene oxide aqueous dispersion: put 0.50g graphene oxide powder and 99.5mL distilled water in a beaker, stir with a magnetic stirrer at room temperature for 10min, and then use an ultrasonic oscillator for 15min to make graphite oxide Graphene powder is evenly dispersed in water to obtain a brown-yellow graphene oxide aqueous dispersion;

[0025] 3. Graphene oxide finishing fabric process: immerse 1.0g of the pretreated fabric in 50mL of the above-mentioned graphene oxide aqueous dispersion for 20min, and use a padding machine to treat the impregnated fabric to remove excess water and keep rolling. The remaining rate is 75-80%. ...

Embodiment 2

[0030] 1. The process is the same as the 1-step process in Example 1.

[0031] 2. The process is the same as the 2-step process in Example 1.

[0032] 3. the number of repetitions is set as 2 times, and all the other are with the 3-step process in embodiment 1 to obtain the graphene oxide finishing fabric that the number of layers is 2.

[0033] 4. The process is the same as the 4-step process in Example 1.

[0034] 5. The process is the same as the 5-step process in Example 1.

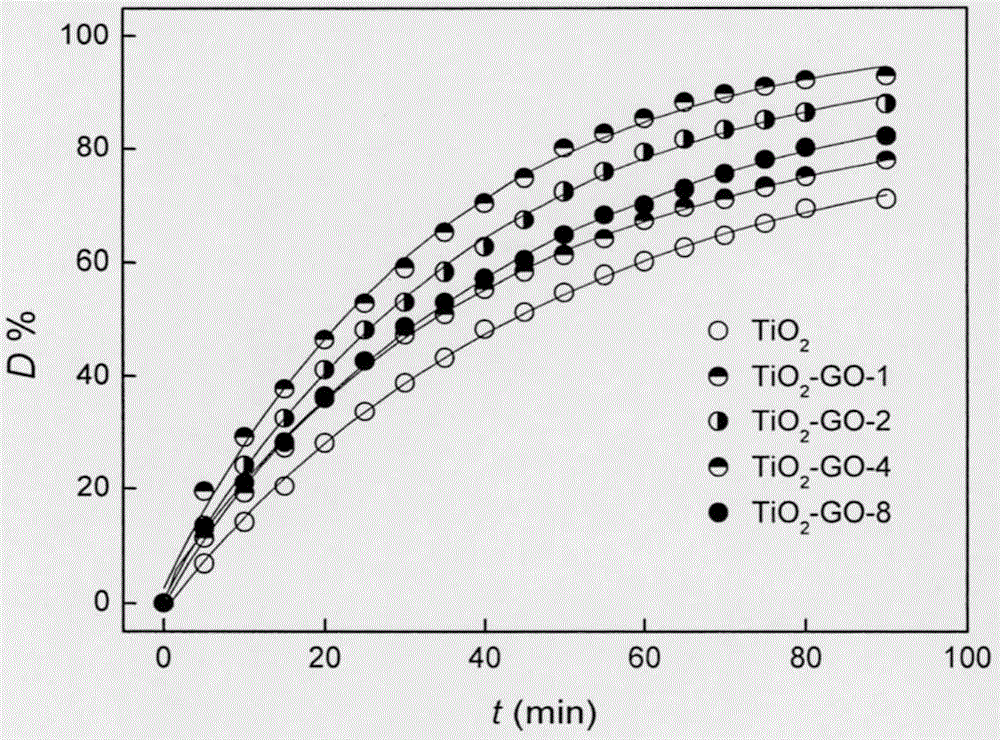

[0035] 6. process is identical with the 6 steps process in embodiment 1, obtains graphene-nano-titanium dioxide composite finishing fabric and is abbreviated as TiO 2 -GO-2.

Embodiment 3

[0037] 1. The process is the same as the 1-step process in Example 1.

[0038] 2. The process is the same as the 2-step process in Example 1.

[0039] 3. the number of repetitions is set to 8 times, and all the other are with the 3-step process in the embodiment 1 to obtain the graphene oxide finishing fabric that the number of layers is 8.

[0040] 4. The process is the same as the 4-step process in Example 1.

[0041] 5. The process is the same as the 5-step process in Example 1.

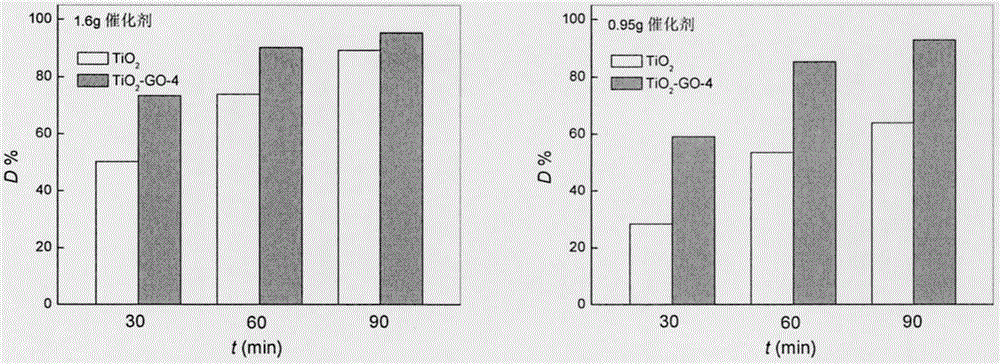

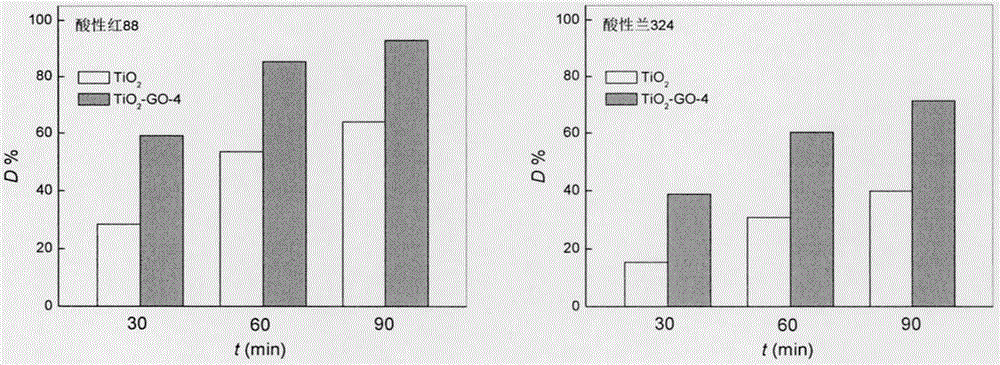

[0042] 6. process is identical with the 6 steps process in embodiment 1, obtains graphene-nano-titanium dioxide composite finishing fabric and is abbreviated as TiO 2 -GO-4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com