Semi-continuous microwave catalytic thermal cracking reactor

A microwave catalysis, semi-continuous technology, applied in the detailed information of chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical processes, etc., to achieve full reaction, solve the problem of material accumulation, and increase the distance of material movement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

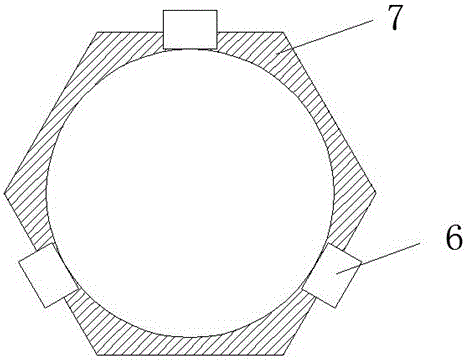

[0022] Such as figure 1 The shown semi-continuous microwave catalytic thermal cracking reactor includes a heating chamber 7 and a microwave heating source 6; wherein the heating chamber 7 is provided with a gas inlet 5, a gas outlet 1, a feed port 2, a feed port 8 and Two temperature measuring ports 4; the feed port 2 is equipped with a feed regulating device 3 to control the feed speed. The microwave heating source 6 outside the heating chamber is adjusted by the control panel 9. The axis of the heating chamber 7 extends in the vertical direction, and a plurality of groups of microwave heating sources 6 are arranged outside of the heating chamber 7, and each group is composed of three microwave heating sources, and they are on the same vertical axis.

[0023] Such as figure 2 The schematic diagram of the top view of the heating chamber shown, the heating chamber 7 has a regular hexagonal structure; the gas inlet 5 is used to pass nitrogen in the experiment to ensure that the e...

Embodiment 2

[0028] Such as Figure 5 As shown, an umbrella-shaped partition is placed in the heating chamber, and the partition is composed of two umbrella-shaped structures. After the material enters the heating chamber through the inlet, it slides down through the outer surface of the umbrella structure. The diameter of the first umbrella structure is 3 to 4 cm smaller than the diameter of the heating chamber; the material falls into the second through the first umbrella edge Inside an inverted umbrella-shaped structure, the diameter of the umbrella-shaped structure is only slightly smaller than the diameter of the heating chamber; the material passes through the umbrella-shaped place a, and drops downward into the second group of umbrella-shaped structures.

[0029] Image 6 It is an enlarged view at a. In this figure, a1 is a pole, which supports the inverted umbrella structure, and a2 is the main pole, which supports the entire structure. The bottom of the inverted umbrella-shaped struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com