A flow distribution mixer for high viscosity medium

A high-viscosity, mixer technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of complex process flow, poor mixing effect of thin and heavy oil, and large flow resistance of mixers, etc., to achieve The additional resistance is small, the uniformity is easy to ensure, and the arrangement density is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

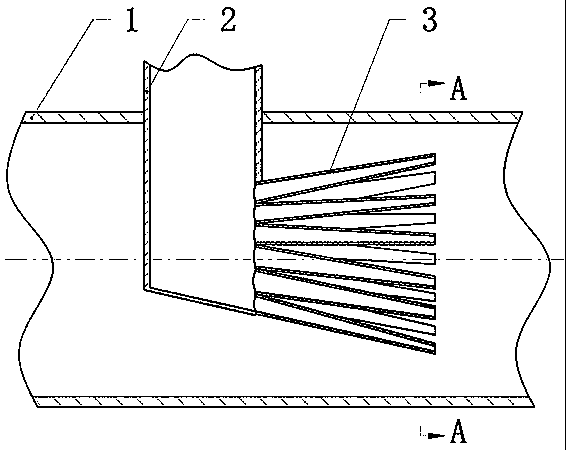

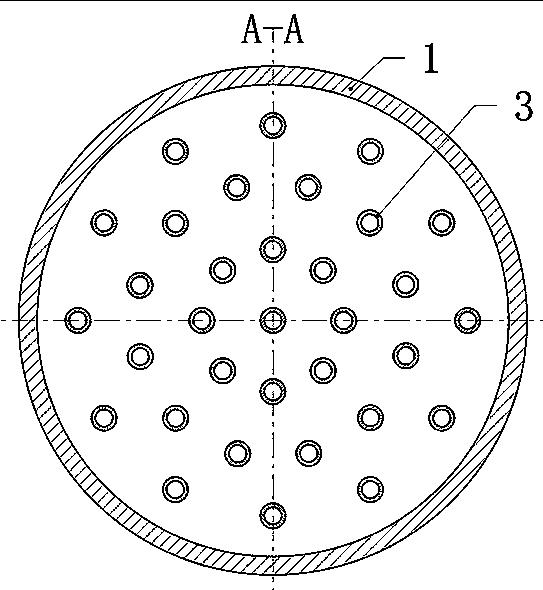

[0015] Combine below figure 1 , figure 2 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

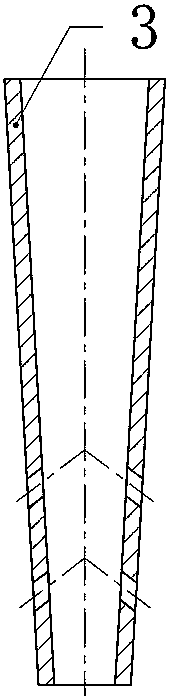

[0016] The branch pipe 2 extends into the pipe body 1 from the side of the pipe body 1, and the pipe body 1 is a high-viscosity medium pipe or a short connection or other partial pipe sections. The finger tubes 3 are tapered cylinders, and the large ends of the finger tubes 3 are welded together and welded to the branch pipe 2; along the fluid flow direction in the tube body 1, a plurality of finger tubes 3 are radially expanded, and the finger tubes 3 The tip spreads out to the entire cross-section of the tube body 1. On the cross-section of the tube body 1 corresponding to the tip of the finger tube 3, the arrangement density of the finger tubes 3 at the center of the tube body 1 is greater than that of the 3 rows of finger tubes at the edge of the tube body 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com