Novel vacuum concentrator

A vacuum concentrator, a new type of technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of environmental hazards, waste of energy, low pollutant concentration, etc., and achieve low maintenance, fast assembly, The effect of high desorption temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

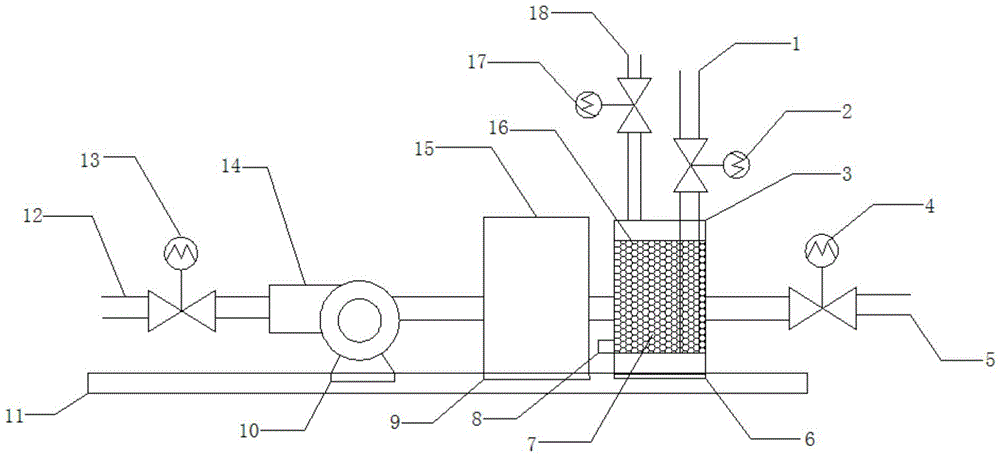

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, a rotary concentrator of the present invention includes a desorption hot air pipeline 1, a desorption air pipeline solenoid valve 2, an adsorption rotor fixing device 3, an adsorption rotor 16, a rotor driving device 8, an adsorption carrier 7, and treated air Pipeline 18, treated air pipeline solenoid valve 17, concentrated desorption exhaust gas pipeline 5, concentrated exhaust gas pipeline solenoid valve 4, fan 14, exhaust gas inlet 12, exhaust gas pipeline solenoid valve 13, fixing plate 11, fan fixing tank 10, pre-filter 15 , pre-filter fixing groove 9 and adsorption rotor fixing device fixing groove 6, fan fixing groove 10, pre-filter fixing groove 9 and adsorption rotor fixing device fixing groove 6 are respectively opened on the fixing plate 11, fan fixing groove 10 is equipped with fan 14. The exhaust gas inlet 12 is on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com