Compact type high-power hollow cathode discharge device

A technology of hollow cathode discharge and hollow cathode, which is applied in the field of plasma, can solve the problems of difficult plasma discharge power, difficulty in increasing plasma power, and low energy utilization efficiency, and achieves low processing cost, wide range of parameter options, and convenient The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

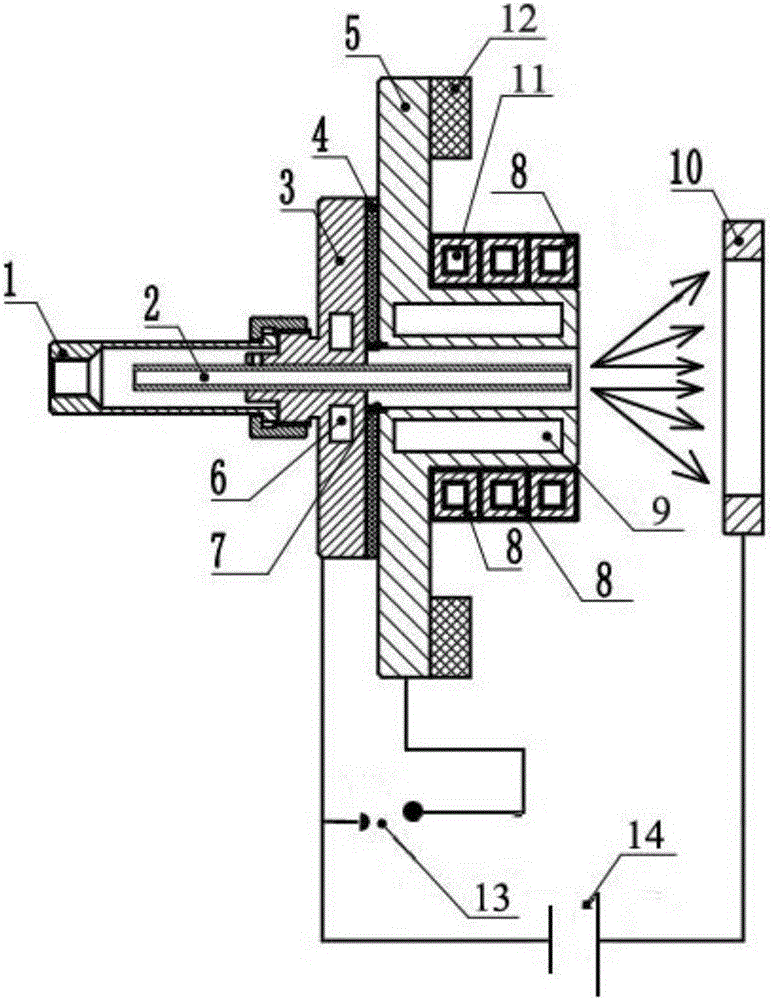

[0035] Such as figure 1 As shown, the present invention provides a high-power, compact plasma source based on hollow cathode discharge, which includes a sealed tube 1, a hollow cathode tube 2, a cathode plate 3, a first insulating plate 4, an auxiliary anode plate 5, An insulating tube 7, a permanent magnet 8, an annular anode plate 10, a third water cooling channel 11 and a control power supply. The hollow cathode tube 2 is installed on the cathode plate 3, which can be a tantalum tube or a tantalum alloy tube, and is locked on the central axis of the cathode plate 3 by screws. The sealed tube 1 is connected to the cathode plate 3, and the hollow cathode tube 2 is sleeved therein to realize the sealing of the hollow cathode tube. The top of the sealed tube is also provided with a gas (such as Ar, He, N2, H2, etc.) A variety of gases) are input to the gas inlet in the hollow cathode tube 2. In this embodiment, when in use, the hollow cathode tube 2 starts to be ablated from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com