Three-phase current transformer model prediction control method free from voltage sensor

A model predictive control and voltage-free sensor technology, which is applied to AC networks, electrical components, and circuit devices with the same frequency from different sources, can solve problems such as the influence of electromotive force harmonics, lower system reliability, and small system sampling periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

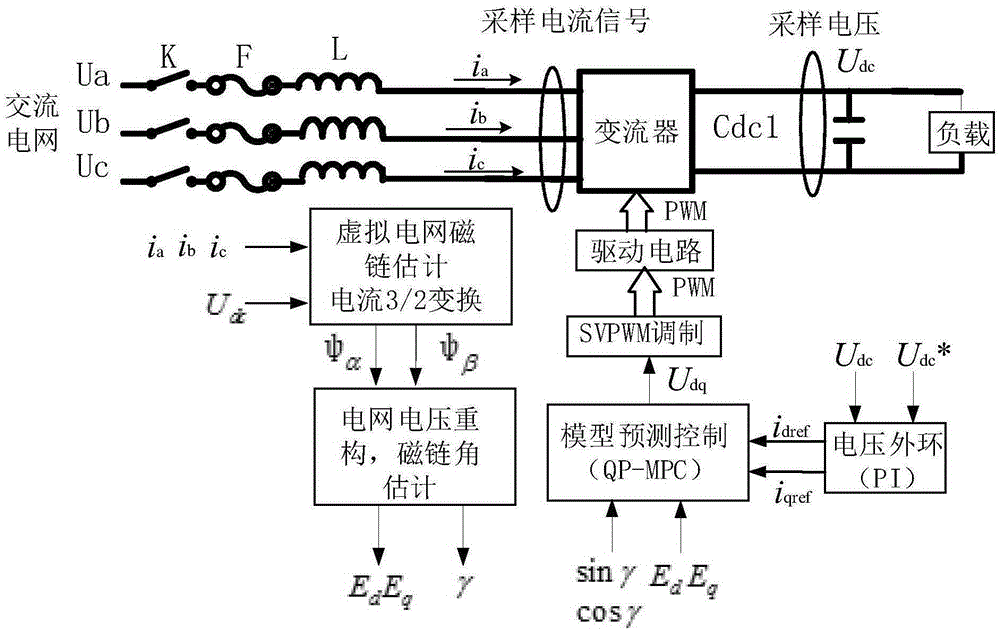

[0035] Refer to attached figure 1 , a control structure block diagram of a voltage sensorless converter model predictive control method provided by the present invention. attached by figure 1 It is known that the control method includes grid voltage and angle reconstruction links, QP-MPC and SVPWM modulation links.

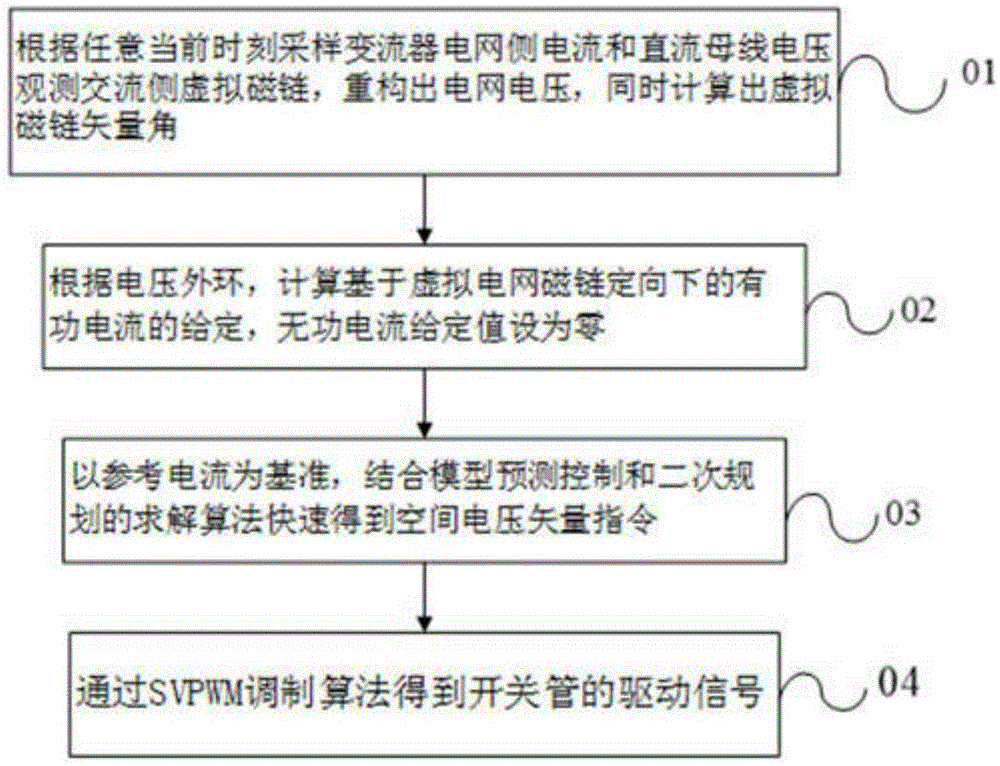

[0036] Refer to attached figure 2 , the converter model predictive control method without voltage sensor comprises:

[0037] Step 01: Observing the virtual flux linkage on the AC side by sampling the grid side current and DC bus voltage of the converter at any current time, reconstructing the grid voltage, and calculating the virtual flux linkage vector angle.

[0038] Step 02: According to the voltage outer loop, calculate the given active current under the no-voltage sensor, and set the given value of reactive current to zero.

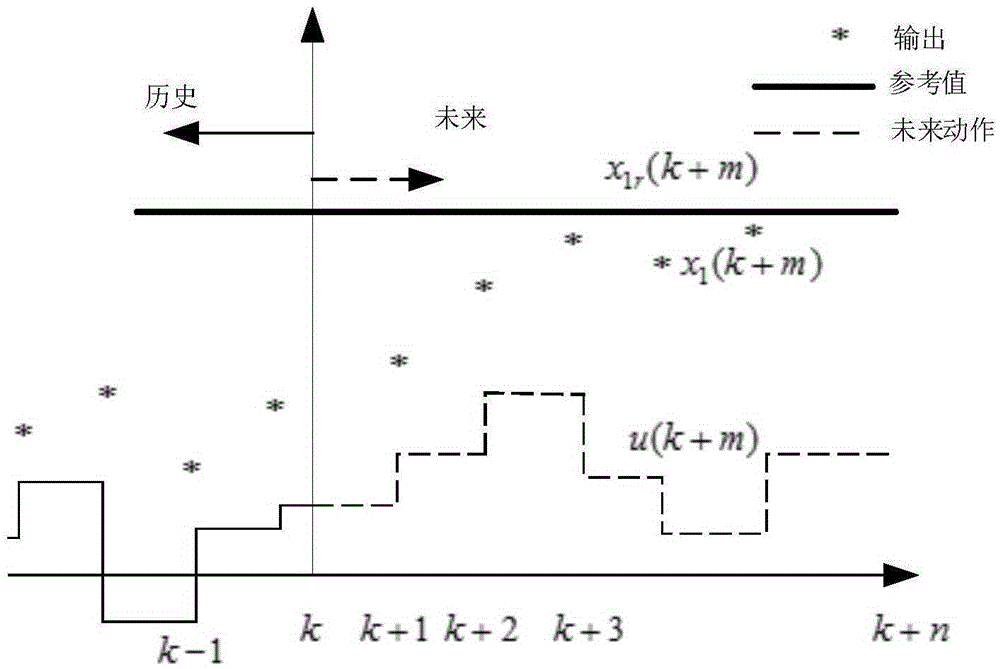

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com