Matching structure for ensuring reliable contact of head portion of sleeve and carrying current

A matching structure and current-carrying technology, which is applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of affecting the operation safety, accelerating the aging of transformer oil and insulation, and increasing the contact resistance between threads, etc. The effects of overheating of the tube head, high structural reliability and reliable current carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

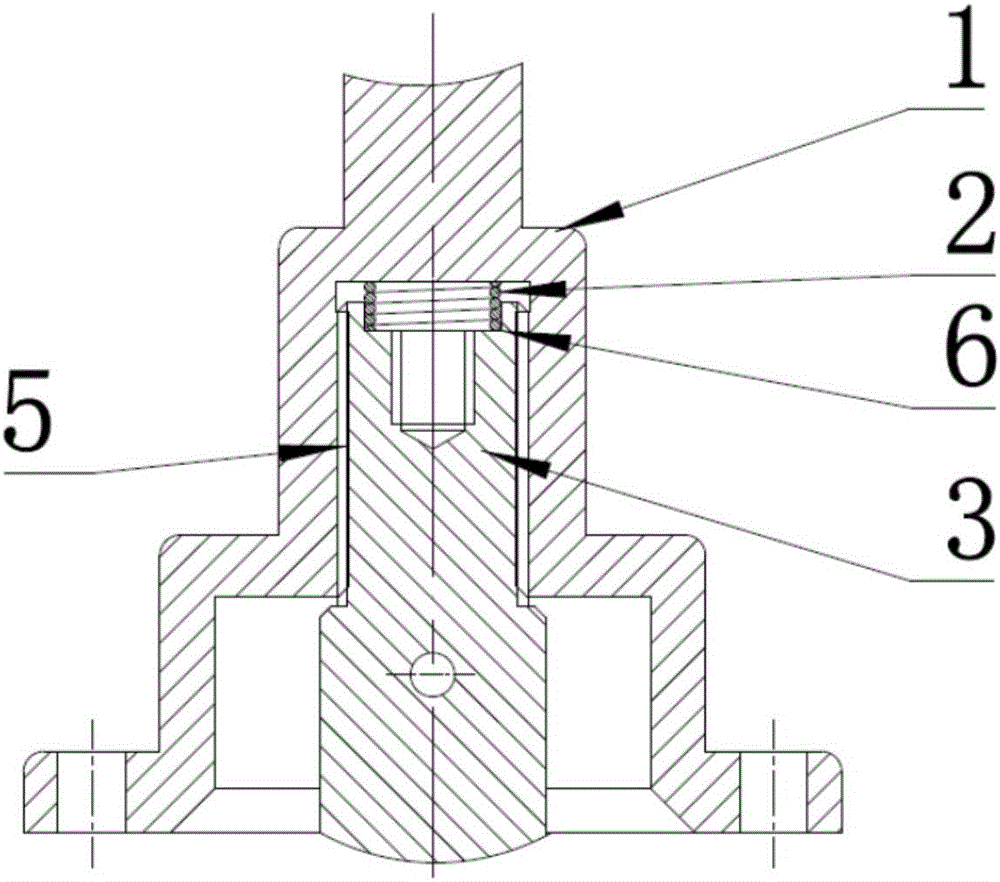

[0017] Such as figure 1 A matching structure to ensure reliable contact of the casing head with current carrying is shown, including a conductive head 1, a spring structure 2 and a lead joint 3, the lead joint 3 and the conductive head 1 are connected and carry current through a thread 5, and the spring structure 2 is For a single spring, a limiting groove 6 is provided on the upper part of the lead connector 3 , and the spring structure 2 is movably placed between the conductive head 1 and the lead connector 3 , and is limited by the limiting groove 6 . When the lead joint 3 is screwed into the conductive head 1 , the spring structure 2 is compressed, and the lead joint 3 and the conductive head 1 are tightly engaged by the force of the spring structure 2 at the thread 5 .

[0018] In the matching structure of this embodiment, both ends of the spring structure 2 are in conflicting contact, and the position is limited only by the limit groove 6. The advantage is that the struc...

Embodiment 2

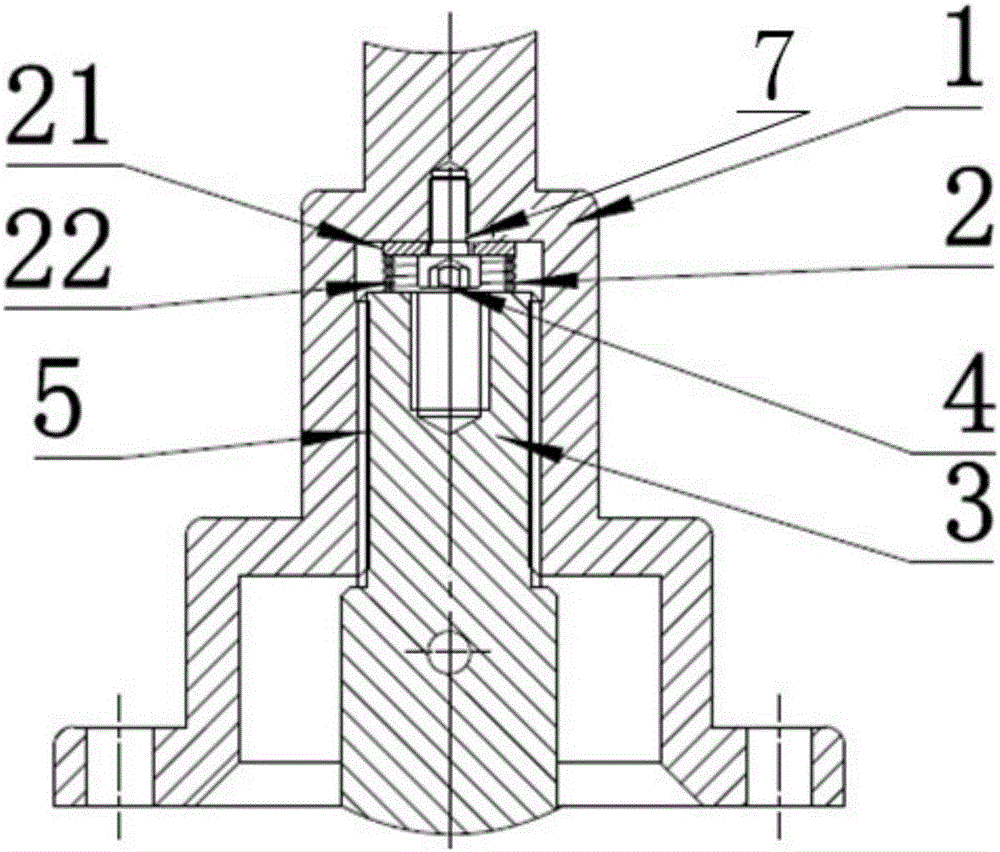

[0020] Such as figure 2 The matching structure shown to ensure reliable contact of the bushing head with current carrying includes a conductive head 1, a spring structure 2 and a lead joint 3, the lead joint 3 and the conductive head 1 are connected and carry current through a thread 5, and the spring structure 2 is set Between the conductive head 1 and the lead joint 3, it includes a spring 22 and a fixed piece 21. The spring 22 is located below the fixed piece 21 and integrally formed with the fixed piece 21. The spring structure 2 is fixed on the conductive head 1 through a fastener 4 as a whole. on the inner surface. The fixing piece 21 and the conductive head 1 are also provided with a fixing hole 7 used in conjunction with the fastener 4 , preferably, the fastener 4 and the fixing hole 7 are threaded. When the lead joint 3 is screwed into the conductive head 1 , the spring structure 2 is compressed, and the lead joint 3 and the conductive head 1 are tightly engaged by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com