A Method for Estimating Vibro-acoustic Fatigue Life of Metal Structures with Uncertainties

An uncertainty, metal structure technology, applied in computing, instrumentation, geometric CAD, etc., can solve problems such as heavy workload, affecting structural mechanical behavior and safety, and only considering the first-order natural frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

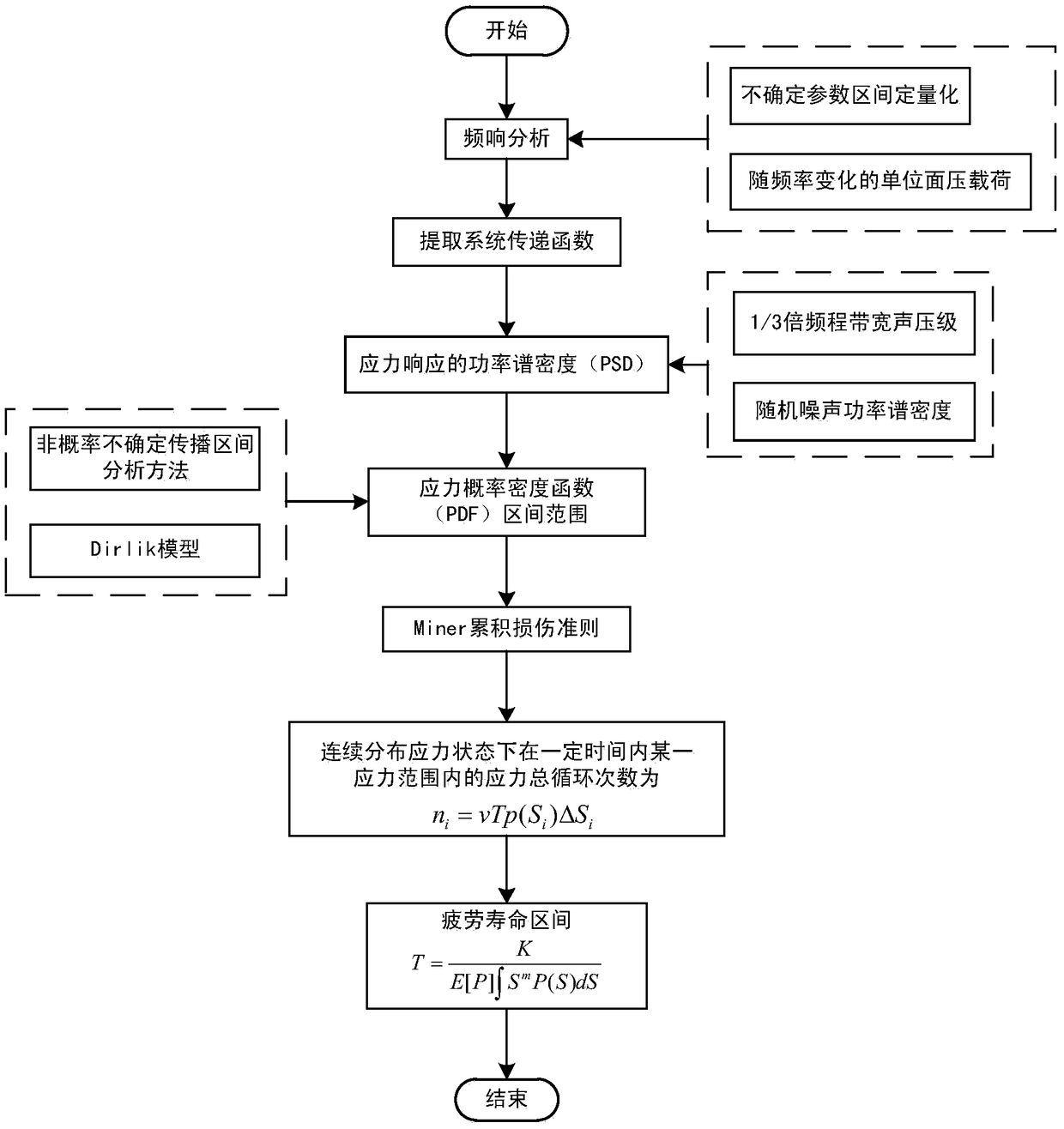

AI Technical Summary

Problems solved by technology

Method used

Image

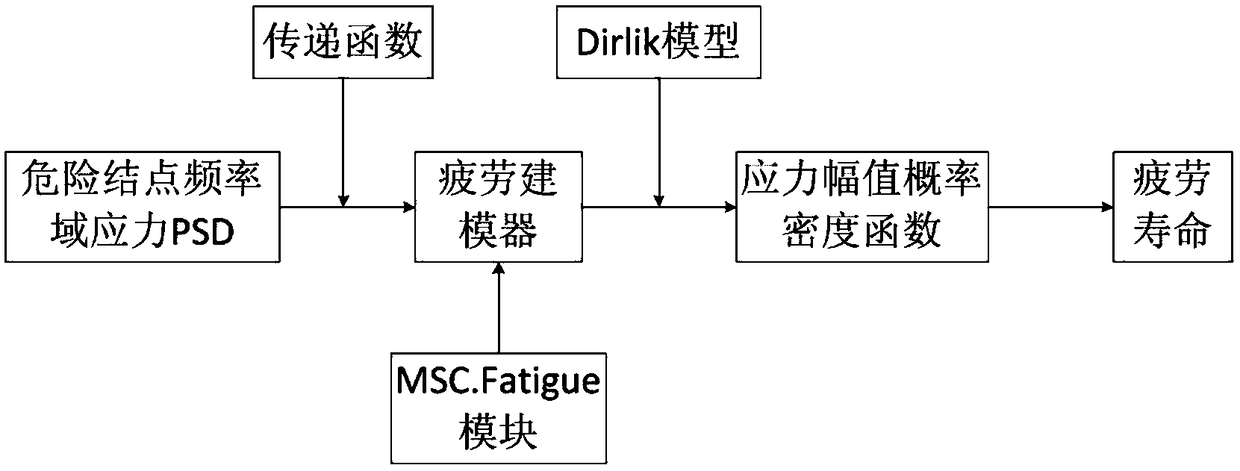

Examples

Embodiment

[0075] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention establishes as image 3 The finite element model of the aircraft cavity structure shown is simplified and boundary conditions are applied. The uncertain information of this model is E=[67.45,74.55]GPa, the system transfer function is calculated after the unit surface pressure that changes with frequency is loaded on the model first, and then the random noise load is applied, and table 2 has provided the embodiment in the model Apply the converted noise power spectral density load (unit Pa 2 / Hz), the first ten natural frequencies of the structure are obtained, and the obtained stress power spectral density function of node 373 is as follows: Figure 4 As shown, the introduced material is 7075 aluminum alloy, and its S-N curve is as follows Figure 5 As shown, the cloud map of life distribution is finally calculated as Figure 6 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com