Mechanics performance testing device for biological soft tissue

A technology of biological soft tissue and testing equipment, which is applied in the field of medical devices, can solve the problems of inability to obtain mechanical performance parameters of biological soft tissue, and achieve the effect of accurate force model, simple operation, and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

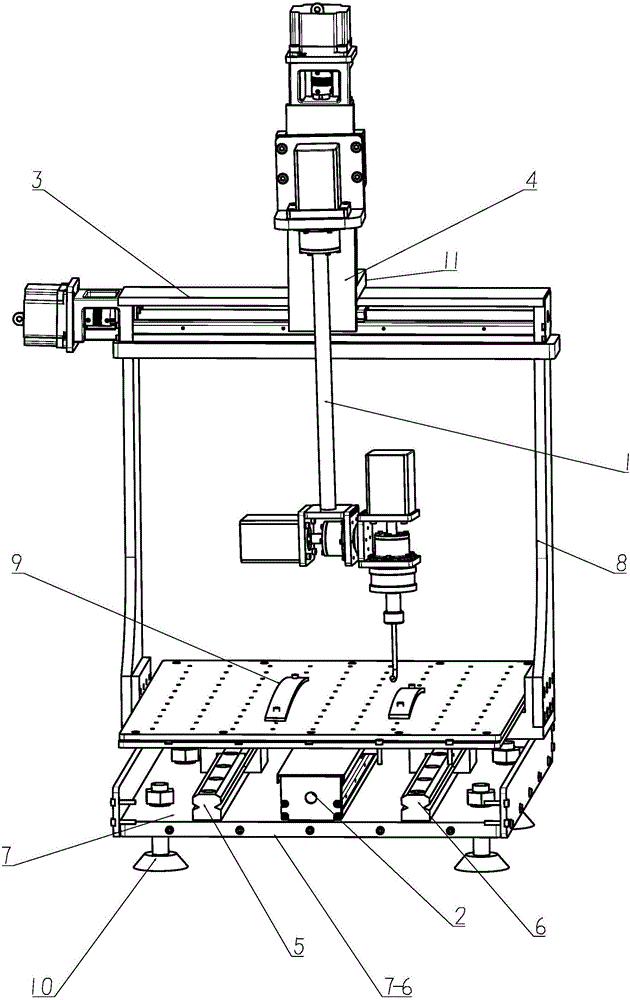

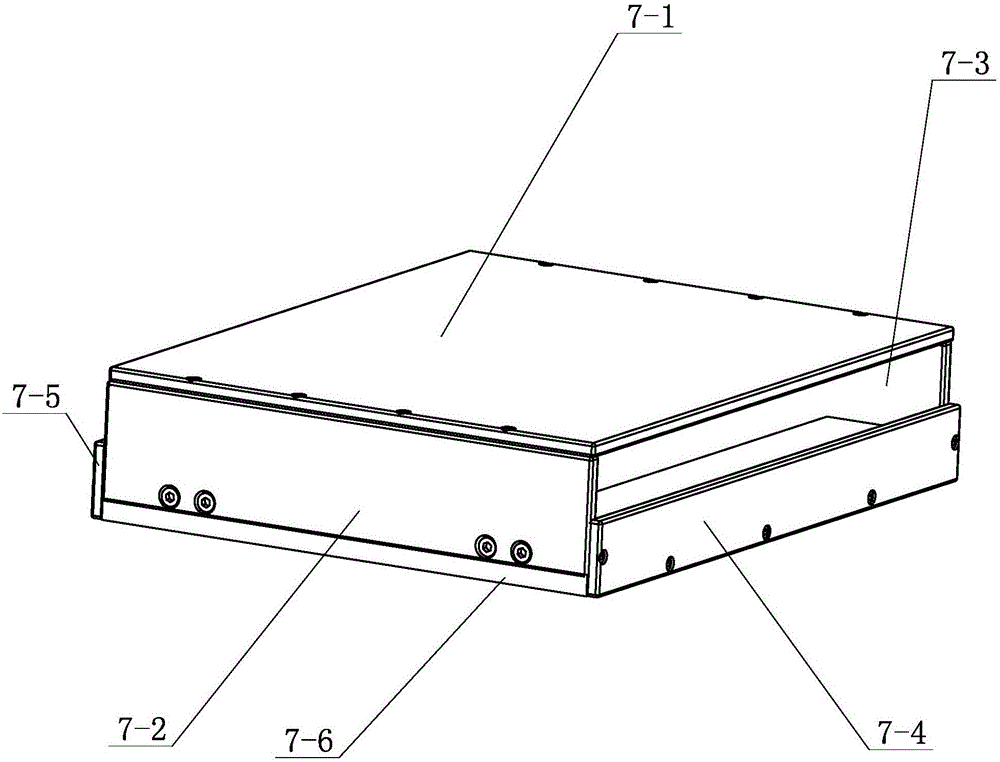

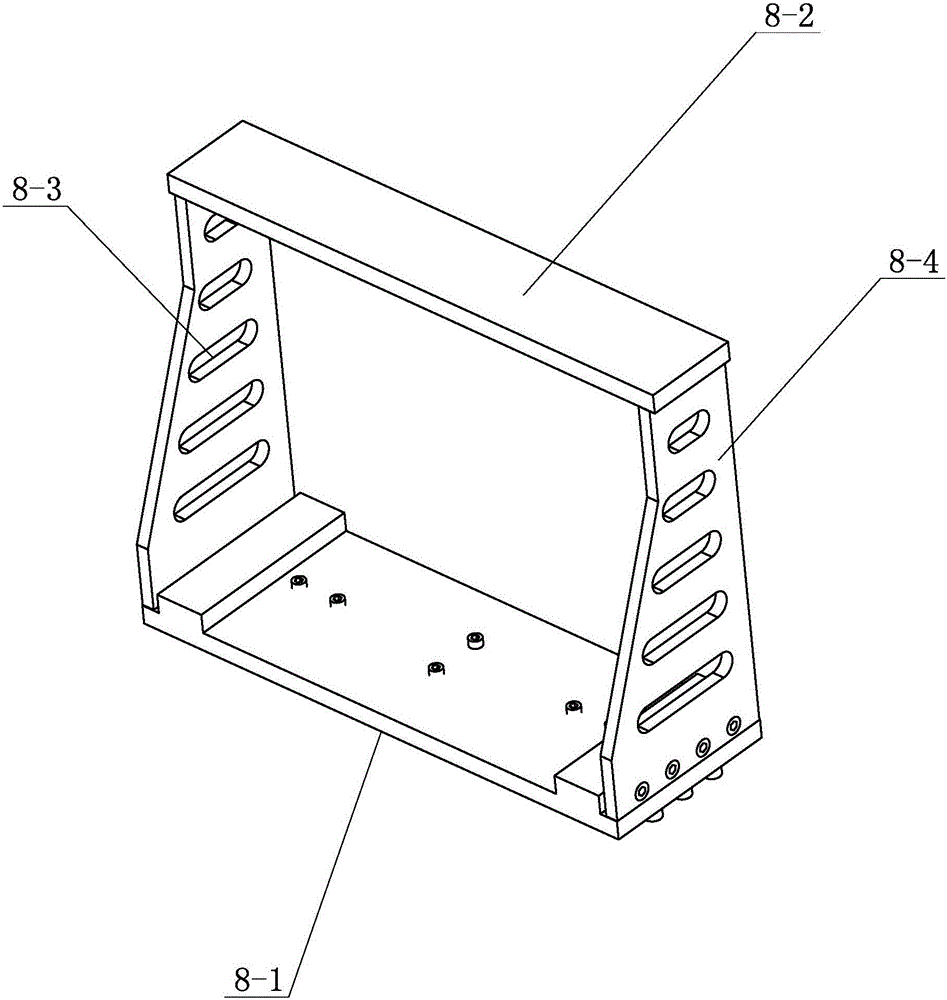

[0016] Specific implementation mode one: combine Figure 1 to Figure 3 This embodiment is described. A device for testing the mechanical properties of biological soft tissue described in this embodiment includes a mechanical arm 1, a first module 2, a second module 3, a third module 4, a first rail assembly 5, and a second rail assembly. Component 6, box body 7, big frame 8, fixture 9 and a plurality of anchor screws 10, box body 7 is made up of upper cover 7-1, front plate 7-2, rear plate 7-3, left side plate 7-4, Right side plate 7-5 and base plate 7-6 are formed, and left side plate 7-4 is vertically installed on the left side of base plate 7-6 upper surface, and right side plate 7-5 is vertically installed on the left side of base plate 7-6 upper surface. Right side, left side plate 7-4, right side plate 7-5, base plate 7-6 form base assembly, and front plate 7-2 is vertically installed on the front end of loam cake 7-1 lower surface, and rear plate 7-3 vertical Installed...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination Figure 4 with Figure 5To illustrate this embodiment, the mechanical arm 1 of a device for testing the mechanical properties of soft biological tissues described in this embodiment includes a first connecting plate 1-1, a first rotating joint 1-2, a second rotating joint 1-3 and a third rotating joint Joint joint 1-4, the third rotary joint 1-4 is installed on the third module 4 through the first connecting plate 1-1, the second rotary joint 1-3 is connected with the third rotary joint 1-4, the first rotary joint The joint 1-2 is connected with the second rotary joint 1-3; the first rotary joint 1-2 includes a first stepper motor 1-21, a first bearing end cover 1-22, a first angular contact ball bearing 1-23, The second angular contact ball bearing 1-24, the first bearing seat 1-25, the first plate 1-26, the second plate 1-27, the third plate 1-28, the first spindle 1-29 six-dimensional sensor 1- 210, sensor flange 1-211,...

specific Embodiment approach 3

[0018] Specific implementation mode three: combination Image 6 Describe this embodiment, the first module 2, the second module 3, and the third module 4 of the biological soft tissue mechanical performance testing device described in this embodiment have the same structure, and the first module 2, the second module 3. The third module 4 includes a module motor 2-1, a module protection cover 2-2, a module sliding table 2-3, a module slider 2-4, a module motor flange 2-5, a module Set screw 2-6, coupling 2-7, first limit switch 2-8, origin switch 2-9 and second limit switch 2-10, module slider 2-4 is installed on the module wire On the bar 2-6, the module sliding table 2-3 is installed on the module slider 2-4, the module protective cover 2-2 is installed on the upper surface of the module, and the module motor 2-1 passes through the module motor flange 2-5 is connected with module leading screw 2-6. Other components and connections are the same as those in the first embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com