A device for testing the fatigue life of flexible bearings with dynamic loading

A flexible bearing and testing device technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems that cannot be used to detect the fatigue life of flexible bearings, and achieve the effect of simple design structure and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

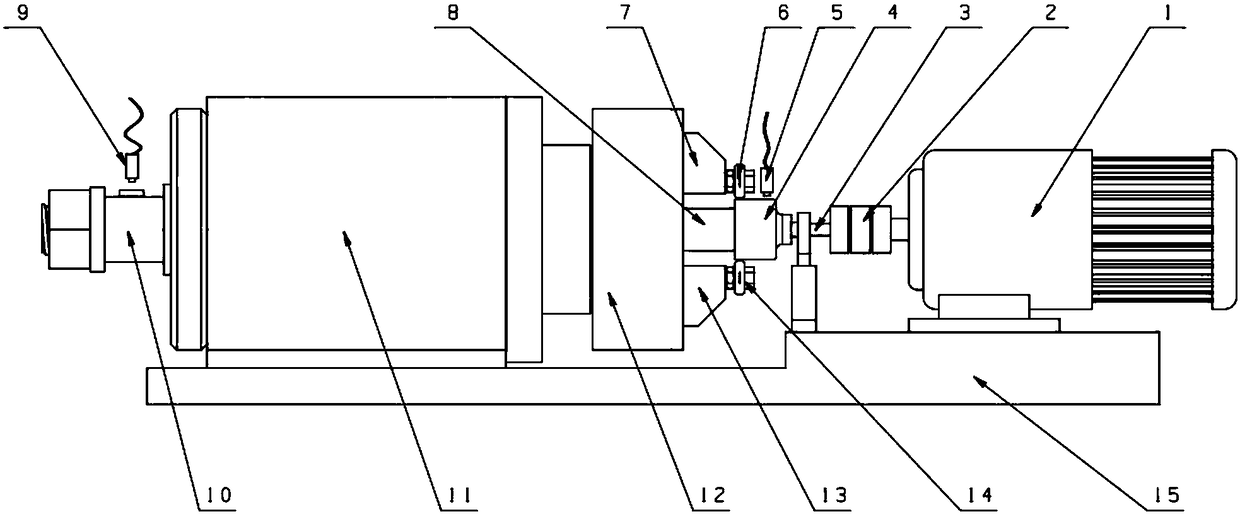

[0023] see Figure 1~Figure 3 , the device for testing the fatigue life of flexible bearings with follow-up loading includes an epicyclic follow-up mechanism and a double independent linkage mechanism. Wheel loading, during the test process, the loading wheel rolls along the surface of the flexible wheel while revolving with the epicyclic follow-up mechanism and loads the flexible bearing through the flexible wheel; the double independent linkage mechanism includes a flexible bearing outer ring rotation drive device and a flexible The inner ring of the bearing rotates the driving device, and the speed ratio of the two driving devices is set according to the test requirements and then starts and stops synchronously.

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

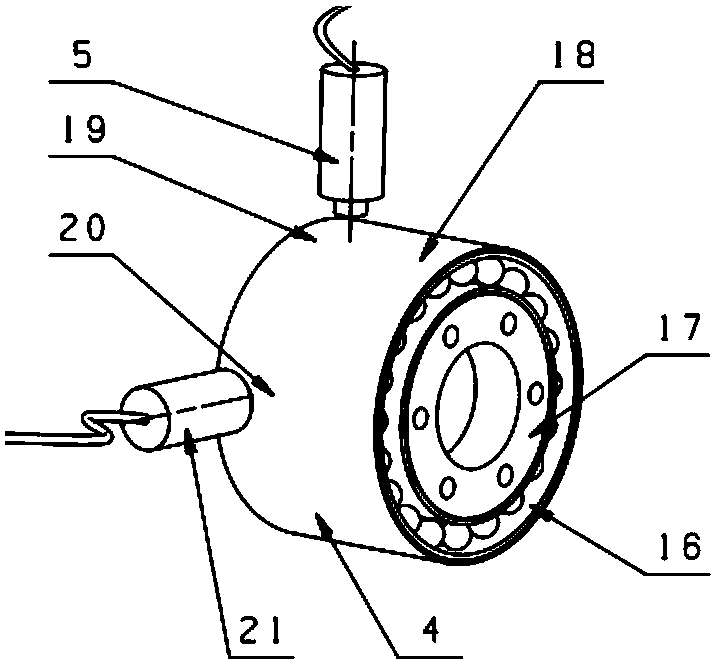

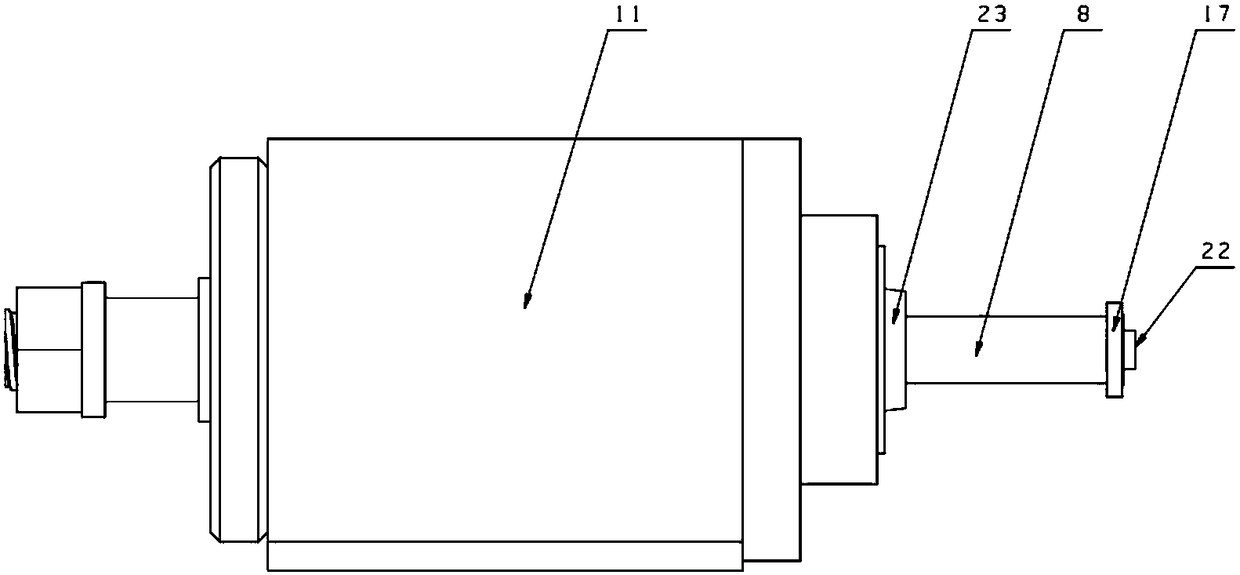

[0026] The double independent linkage mechanism includes a base support plate (15), a flexible bearing outer ring rotary drive device and a flexible bearing inner ring rotary drive device; wherein the flexible bearing inner ring rotary drive device includes a main shaft (8), a driver (11), The wave generator (17), the tested flexible bearing (16) and the counting sensor (9); wheel (4), counting sensor (9) and flaw detection sensor (5); wherein the main shaft (8) is driven to rotate by the driver (11), the wave generator (17) is installed at the front end (22) of the main shaft, and the tested flexible bearing (16) Installed on the wave generator (17), the flexspline (4) is set on the outer ring of the tested flexible bearing; the flexspline connecting rod (3) is fixedly connected with the flexspline (4), and the driver (1) passes The coupling (2) connects the flexspline co...

Embodiment 3

[0033] Such as figure 1 , figure 2 A kind of follow-up loading flexible bearing fatigue life testing device shown includes epicyclic follow-up mechanism and double independent linkage mechanism, turntable (12), moving claws (7, 13), loading wheels (6, 14) and wrapped in Elastic rubber on the outer ring of the loading wheel; the double independent linkage mechanism includes: driver (1, 11), main shaft (8), wave generator (17), flexible bearing (16), flexible wheel (4), shaft coupling (2), flexspline connecting rod (3), flaw detection sensor (5), counting sensor (9, 21) and base support plate (15), driver (1) is connected to flexspline connecting rod through coupling (2) ( 3) Drive the flexible spline (4) to rotate.

[0034] Such as figure 1 , figure 2 As shown, the flexible bearing (16) is installed on the wave generator (17), and the wave generator (17) is an elliptical outer contour coat, and the tested flexible bearing (16) is inserted into the wave generator (17) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com