A dynamic test method for stress relaxation of torsion springs

A technique for stress relaxation, dynamic testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

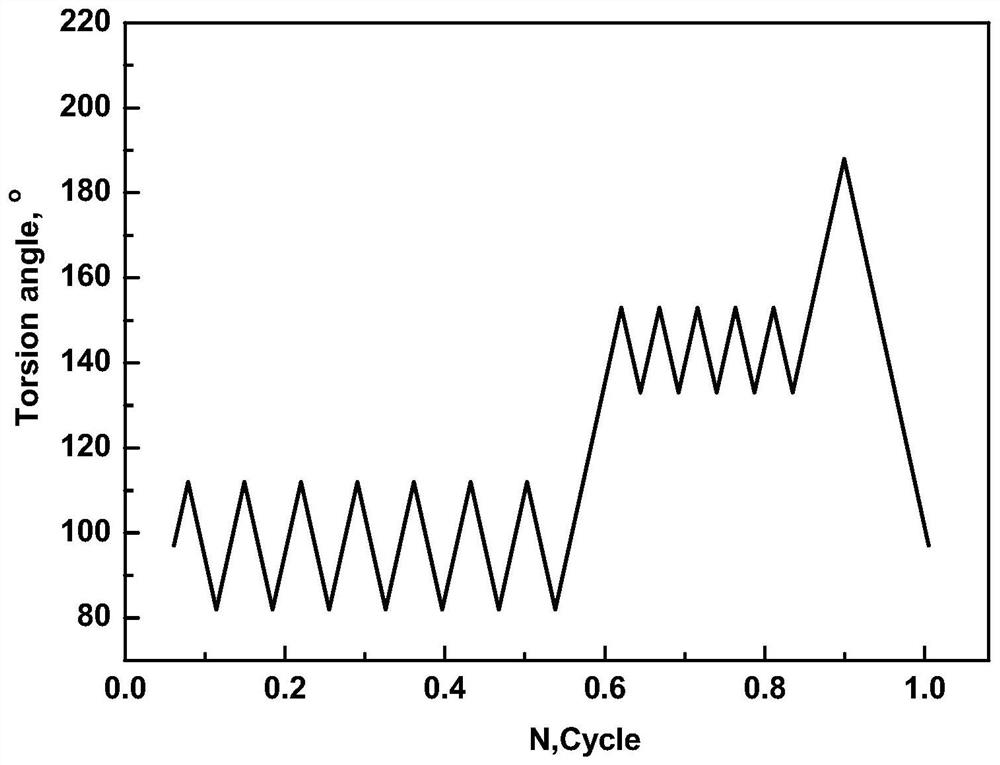

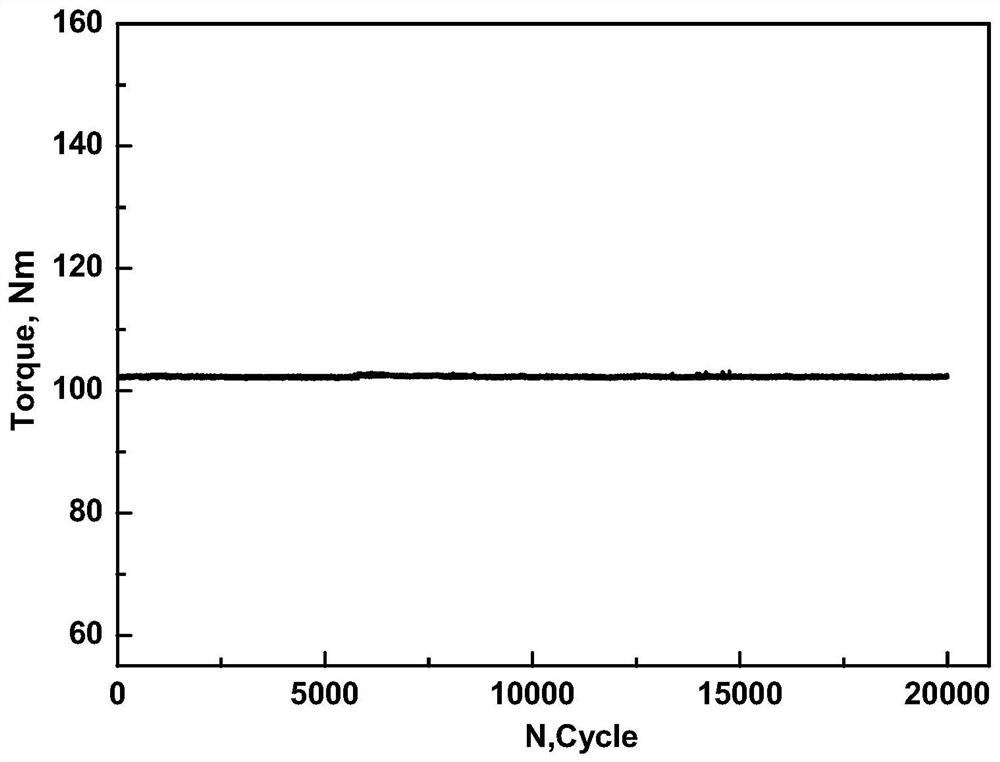

[0049] In this embodiment, the actual working condition parameters of the torsion spring are shown in Table 1 below, and the torsion spring has completed 20,000 working cycle stress relaxation tests, and the working cycle curve of each cycle is shown in figure 1 , from Table 1 and figure 1 It can be seen that the actual working condition of the torsion spring is: first load the torsion spring to the minimum torsion angle of 97°→vibrate 7 times near (97°±15°), and finally stop at 97°→continue to load the torsion spring to 143°, and there are (143±10)°vibrations for 5 times, and finally stop at the fretting angle of 143°→continue to load to the maximum torsion angle of 188°→unload to the minimum torsion angle of 97°. After each working cycle of the torsion spring, measure the torque value of its maximum torsion angle of 188°, and compare it with the initial torque value before the test. If the torque value decreases by more than 5%, the test ends; if the torque value decreases b...

Embodiment 2

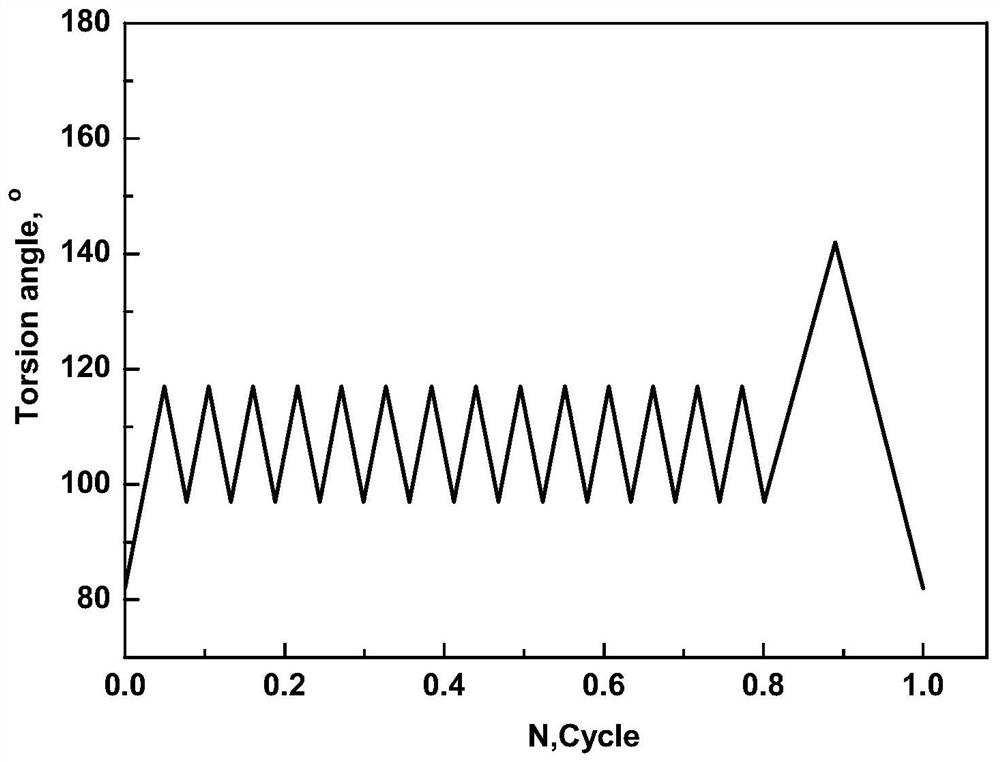

[0056] In this embodiment, the actual working condition parameters of the torsion spring are shown in Table 3 below, and the torsion spring has completed 15,000 working cycle stress relaxation tests, and the working cycle curve of each cycle is shown in image 3 , from Table 3 and image 3 It can be seen that the actual working condition of the torsion spring is: first load the torsion spring to the minimum torsion angle of 82°→continue to load to the inching angle of 107°→vibrate 14 times near (107°±10°), and finally stop At the micro-motion angle of 107°→continue to load to the maximum torsion angle of 142°→unload to the minimum torsion angle of 82°. After each working cycle of the torsion spring, measure the torque value of its maximum torsion angle of 142°, and compare it with the initial torque value before the test. If the torque value decreases by more than 10%, the test ends; if the torque value decreases by less than 10%, continue The test ends after 15,000 working c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com