Low-cost high-strength high-toughness high-thermal conductivity wrought magnesium alloy and preparation method thereof

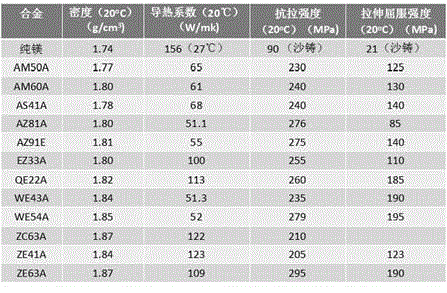

A low-cost technology for deforming magnesium alloys, applied in the field of deformation processing of metal materials and non-ferrous metal materials, can solve the problems of high cost and failure to solve the thermal conductivity of alloys, and achieve the effect of low cost, excellent comprehensive performance and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

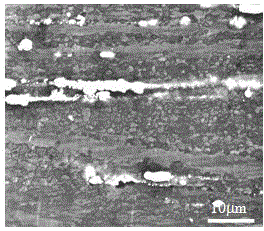

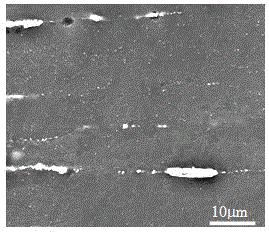

Image

Examples

Embodiment 1

[0055] (1) The design mass percentage of Mg-2.5Zn-0.3Ca-0.4La-0.3Mn is proportioned according to the above, and the materials described are pure Mg ingot, pure Zn ingot, Mg-15wt%Ca, Mg-1.5wtMn intermediate alloy, Mg-20wt%La master alloy;

[0056] (2) Melting:

[0057] Put the above-mentioned pure Mg ingot and Zn ingot into the melting furnace, at 780°C, SF 6 After complete melting under gas protection, add Mg-Ca\Mg-Mn master alloy, adjust the temperature and set the temperature at 750℃, SF 6 Melt completely under gas protection; then add Mg-La master alloy, at 750℃, SF 6 Melt completely under gas protection, and add RJ-5 flux to cover the surface of the melt at the same time; then adjust the temperature in the furnace to 780°C, and pass Ar gas preheated at 750°C into the melt, and add RJ-5 flux at the same time Carry out refining for 5-15 minutes to obtain a refined melt; then transfer the refined melt to a static furnace under a pressure of 0.01-0.02 MPa, let it stand at 7...

Embodiment 2

[0063] The difference between this embodiment 2 and the embodiment 1 is that: the ratio of the alloy components by mass percentage is Mg-1.5Zn-0.3Ca-0.4La-0.4Mn.

[0064] The performance at room temperature of the low-cost, high-strength, high-toughness, and high-thermal conductivity deformable magnesium alloy prepared in Example 2: the tensile strength is 336MPa, the yield strength is 311MPa, the elongation is 30%, and the thermal conductivity is about 135W.(m.K) -1 .

Embodiment 3

[0066] The difference between Example 3 and Example 1 is: the alloy composition ratio is Mg-1.5Zn-0.3Ca-0.4La-0.1Mn in mass percent;

[0067] It is detected that the comprehensive properties of the low-cost, high-strength, high-toughness, and high-thermal conductivity deformed magnesium alloy prepared in Example 3 at room temperature: the tensile strength is 330MPa, the yield strength is 325MPa, the elongation is 33%, and the thermal conductivity is about 140W. ( m.K) -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com