A kind of bacterial cellulose dry film and its preparation method and application

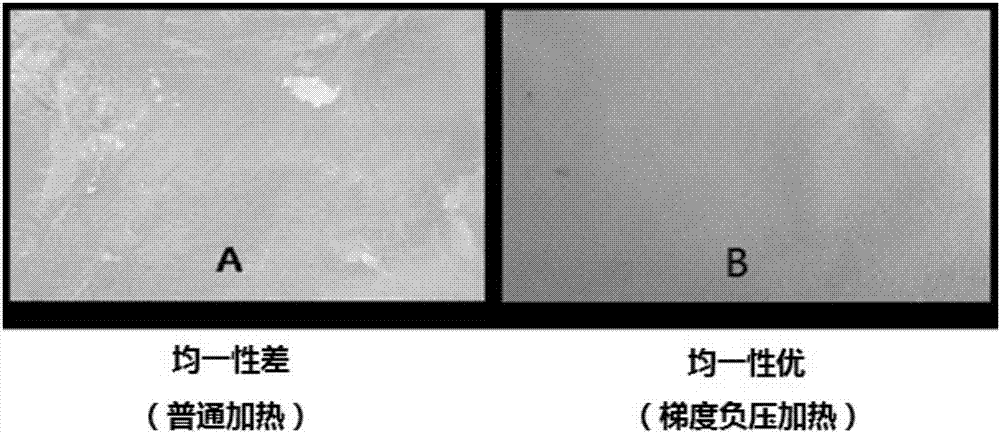

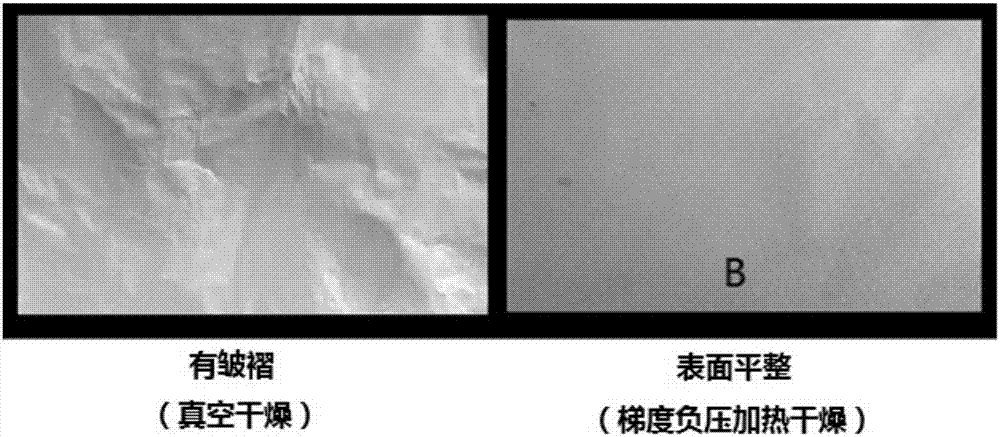

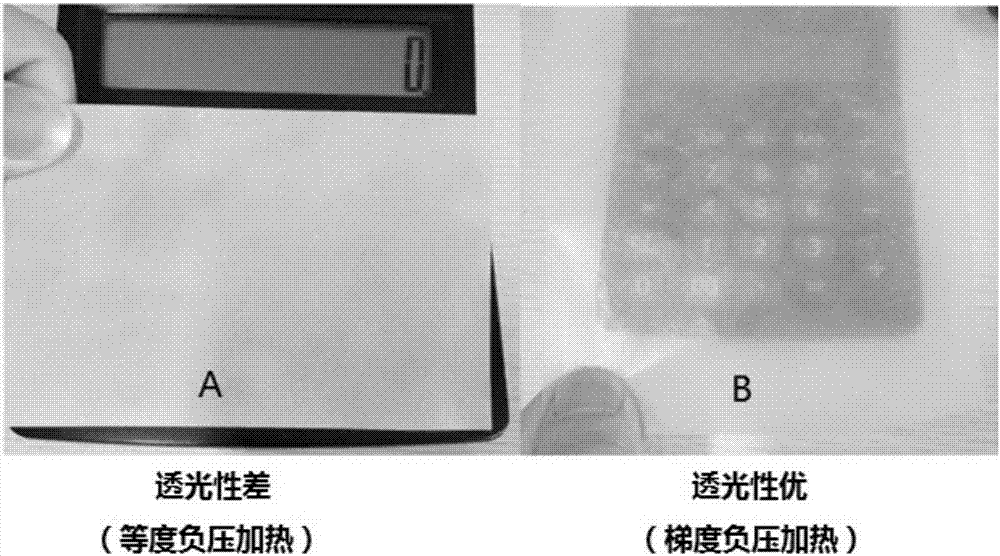

A technology of bacterial cellulose and dry film, applied in medical science, prosthesis, etc., can solve problems such as poor uniformity and permeability, uneven heating, loss of fine fibers, etc., to ensure the pressing density, ensure the flatness, and accelerate the diffusion speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation method:

[0045] (1) Wash the BC wet film with a buffer solution at normal temperature and with an osmotic pressure equal to that of the culture medium to remove bacteria and culture medium remaining on the surface.

[0046] (2) Soak BC wet film with 0.1-0.5M NaOH for 2-3 days. Need to replace new NaOH solution several times in the middle.

[0047] (3) Neutralize NaOH with dilute hydrochloric acid until the pH of the soaking solution is weakly acidic.

[0048] (4) Wash the BC wet film with deionized water at room temperature, press the surface of the BC wet film lightly with pH test paper, and the result is neutral.

[0049] (5) The BC wet film soaked in deionized water is subjected to ultrasonic treatment to fully swell, and the working conditions are 30-100kHz, 50-150W.

[0050] (6) heating and shaping the swollen wet film after treatment under gradient negative pressure heating conditions,

[0051] Described gradient negative pressure heating condi...

Embodiment 2

[0066] (1) Wash the BC wet film with a buffer solution at normal temperature and with an osmotic pressure equal to that of the culture medium to remove bacteria and culture medium remaining on the surface.

[0067] (2) Soak BC wet film with 0.1-0.5M NaOH for 2-3 days. Need to replace new NaOH solution several times in the middle.

[0068] (3) Neutralize NaOH with dilute hydrochloric acid until the pH of the soaking solution is weakly acidic.

[0069] (4) Wash the BC wet film with deionized water at room temperature, press the surface of the BC wet film lightly with pH test paper, and the result is neutral.

[0070] (5) The BC wet film soaked in deionized water is subjected to ultrasonic treatment to fully swell, and the working conditions are 30-100kHz, 50-150W.

[0071] (6) heating and shaping the swollen wet film after treatment under gradient negative pressure heating conditions,

[0072] Described gradient negative pressure heating condition is:

[0073] A: 0-60min, ne...

Embodiment 3

[0076] (1) Wash the BC wet film with a buffer solution at normal temperature and with an osmotic pressure equal to that of the culture medium to remove bacteria and culture medium remaining on the surface.

[0077] (2) Soak BC wet film with 0.1-0.5M NaOH for 2-3 days. Need to replace new NaOH solution several times in the middle.

[0078] (3) Neutralize NaOH with dilute hydrochloric acid until the pH of the soaking solution is weakly acidic.

[0079] (4) Wash the BC wet film with deionized water at room temperature, press the surface of the BC wet film lightly with pH test paper, and the result is neutral.

[0080] (5) The BC wet film soaked in deionized water is subjected to ultrasonic treatment to fully swell, and the working conditions are 30-100kHz, 50-150W.

[0081] (6) heating and shaping the swollen wet film after treatment under gradient negative pressure heating conditions,

[0082] Described gradient negative pressure heating condition is:

[0083] A: 0-30min, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com