Epoxy resin composition and preparation method thereof

A technology of epoxy resin and resin mixture, which is applied in the field of organic synthetic polymer materials, can solve the problems of low-cost preparation of high-temperature-resistant epoxy composite materials, and achieve short preparation cycle, low preparation cost and low room temperature viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An epoxy resin composition, its components (mass parts) are 100 parts of 4,4'-diaminodiphenylmethylene glycidyl amine (epoxy 1), 20 parts of five-membered diaza rings Epoxy resin (epoxy 2), 150 parts methyltetrahydrophthalic anhydride (anhydride 1), 1.5 parts 2,4,6-tris-(dimethylaminomethyl)phenol (accelerator 1).

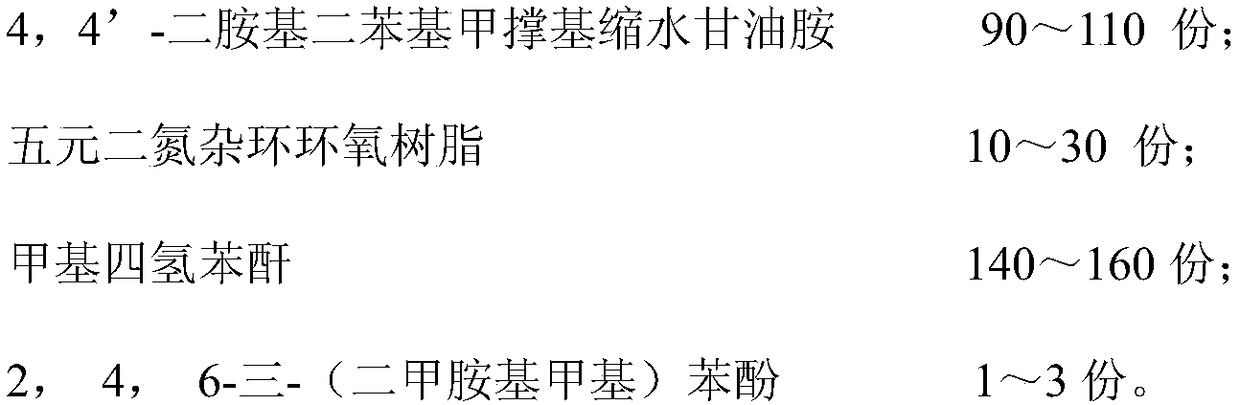

[0027] Among them, the molecular formula of 4,4'-diaminodiphenylmethylene glycidylamine is:

[0028]

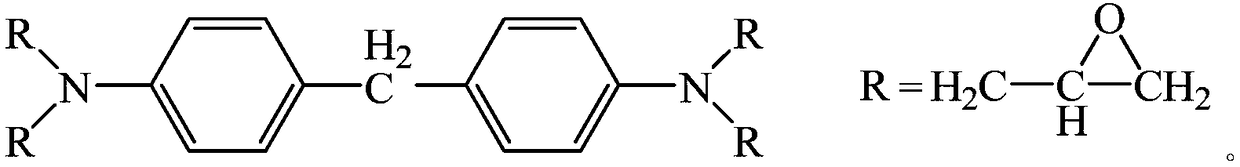

[0029] The molecular structural formula of the five-membered diazocyclic epoxy resin is:

[0030]

[0031] The molecular structural formula of methyltetrahydrophthalic anhydride is:

[0032]

[0033] The molecular structural formula of 2,4,6-tri-(dimethylaminomethyl)phenol is:

[0034]

[0035] The preparation method of above-mentioned epoxy resin composition, comprises the following steps:

[0036] S1. Add 100 parts by mass of 4,4'-diaminodiphenylmethylene glycidylamine and 20 parts by mass of five-membered diazacyclic epoxy resin into the r...

Embodiment 2

[0041] An epoxy resin composition, its components (mass parts) are 110 parts of 4,4'-diaminodiphenylmethylene glycidyl amine (epoxy 1), 10 parts of five-membered diaza rings Epoxy resin (epoxy 2), 140 parts methyltetrahydrophthalic anhydride (anhydride 1), 2 parts 2,4,6-tris-(dimethylaminomethyl)phenol (accelerator 1).

[0042] The preparation method of above-mentioned epoxy resin composition, comprises the following steps:

[0043] S1. Add 110 parts by mass of 4,4'-diaminodiphenylmethylene glycidylamine and 10 parts by mass of five-membered diazacyclic epoxy resin into the reactor and mix them, and heat up to 48°C , stir 2h with 1250rpm stirring speed, then naturally cool to room temperature, obtain the mixture of two kinds of epoxy resins;

[0044] S2, adding 2,4,6-tri-(dimethylaminomethyl)phenol in 2 parts by mass to the mixture of two epoxy resins, stirring at 1250 rpm for 2 hours at room temperature, and standing for 28 hours, obtain a resin mixture;

[0045] S3. Mix t...

Embodiment 3

[0048] An epoxy resin composition, its components (mass parts) are 90 parts of 4,4'-diaminodiphenylmethylene glycidyl amine (epoxy 1), 30 parts of five-membered diaza rings Epoxy resin (epoxy 2), 160 parts methyltetrahydrophthalic anhydride (anhydride 1), 2 parts 2,4,6-tris-(dimethylaminomethyl)phenol (accelerator 1).

[0049] A preparation method of the low-viscosity and high-temperature-resistant epoxy resin system of this embodiment, the steps are the same as in Embodiment 1.

[0050] In this example, the glass transition temperature of the obtained epoxy resin composition is 200°C, the initial viscosity at room temperature is 800mPa·s, and the low viscosity plateau time at 45°C can reach 186min, the above parameters are obviously better than those in the prior art epoxy resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com