Rotary type microwave wastewater treatment device

A wastewater treatment, rotary technology, applied in the field of rotary microwave wastewater treatment devices, can solve the problems of high cost and low efficiency, and achieve the effect of saving energy and saving use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

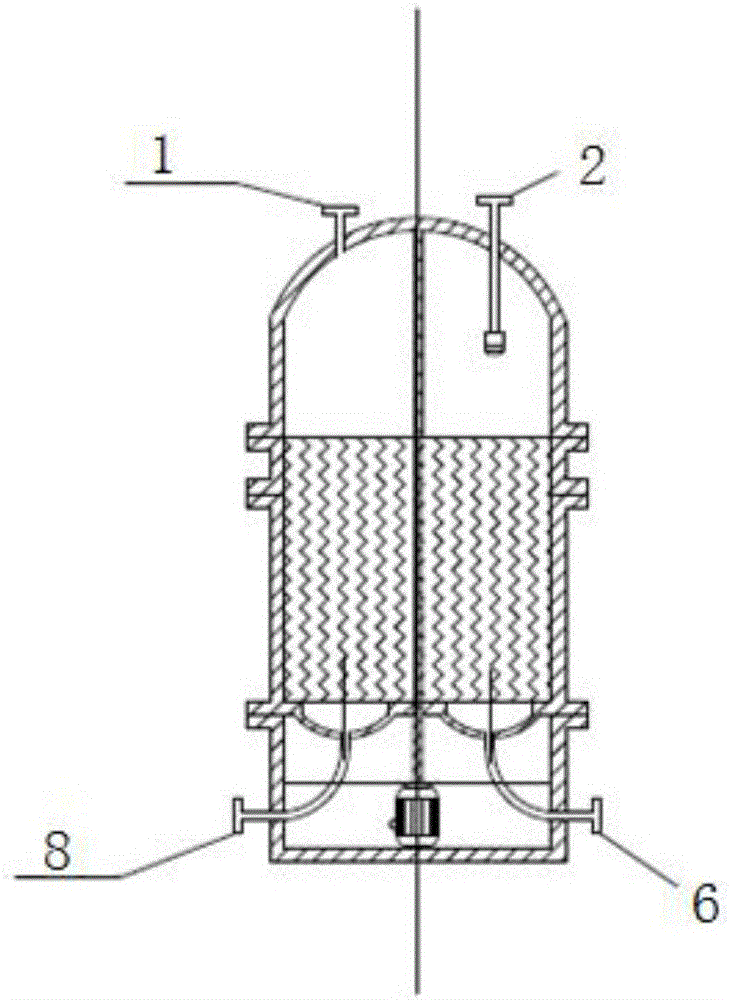

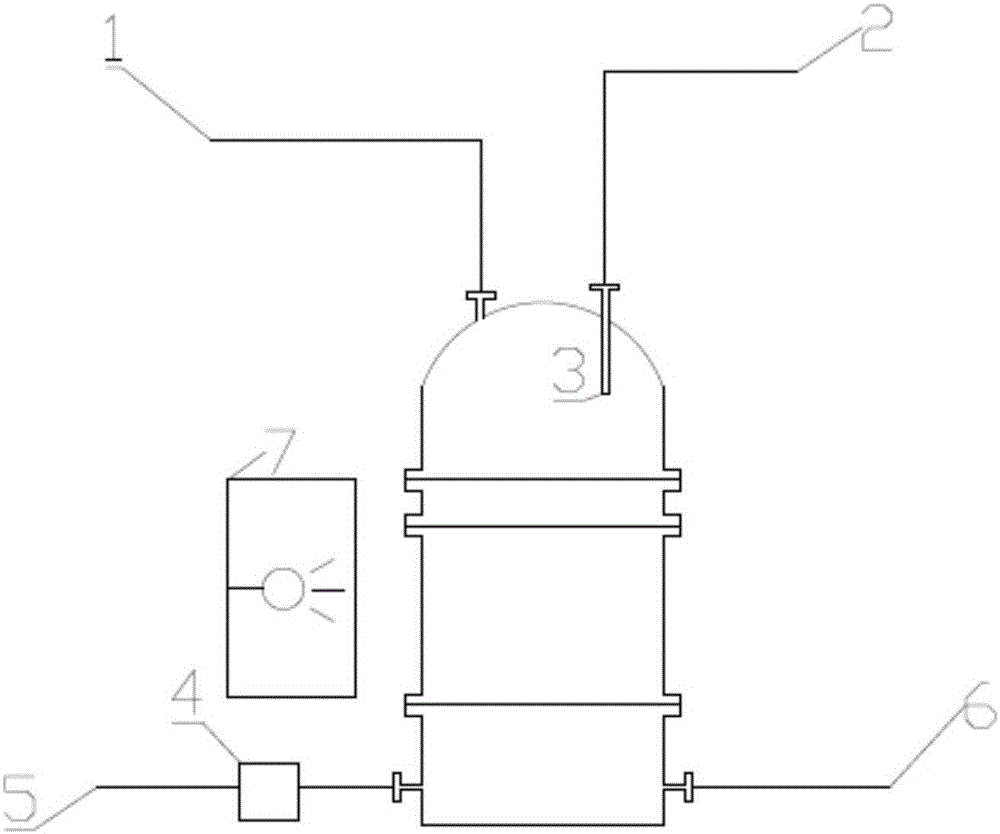

[0041] Such as figure 1As shown, a rotary microwave wastewater treatment device includes a housing, a reaction chamber, and a microwave generator 7 arranged on one side of the reaction chamber. The interior of the housing is divided into two symmetrical parts by a partition, and the adsorption chamber and the degradation and regeneration chamber, the upper and lower ends of the housing are provided with an air inlet 1, an air outlet 5, a liquid inlet 2 and a liquid outlet 6, and the air inlet 1 and the air outlet 5 are located on the same side of the partition, And be arranged at different ends of the housing, the liquid inlet 2 and the liquid outlet 6 are also located on the same side of the partition, and are arranged at different ends of the housing; the reaction chamber is located in the middle of the housing, and the reaction chamber is set There is a catalyst layer, and the catalyst layer can rotate.

[0042] The catalyst layer is a catalyst plate, the catalyst plate is...

Embodiment 2

[0055] The catalyst layer is a fine network structure, filled with catalyst, and the catalyst is activated carbon supported FeSO 4 .

[0056] The wall of the housing where the reaction chamber is located is fixed, and the catalyst plate can rotate relative to the housing driven by the motor and the rotating shaft.

[0057] Firstly, the organic liquid enters through the liquid inlet 2, passes through the liquid distributor 3, and evenly flows through the activated carbon adsorbent. After the activated carbon is saturated, the device is rotated, the microwave generator 7 is turned on, and the oxidizing gas is introduced to catalyze the oxidation of the organic matter. The gas contains a relatively large amount of water vapor. After the gas is cooled by the gas cooler 4, the gas-liquid is separated. After the oxidation process is completed, the nitrogen protective gas is introduced from the air inlet 1 to regenerate the activated carbon. In this way, you can get A nearly continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com