Yoga mat winding device

A kind of yoga, bending technology, applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems that the winding cannot be completed effectively, the adsorption effect is not ideal, etc., to avoid equipment waiting time, not easy to skew, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

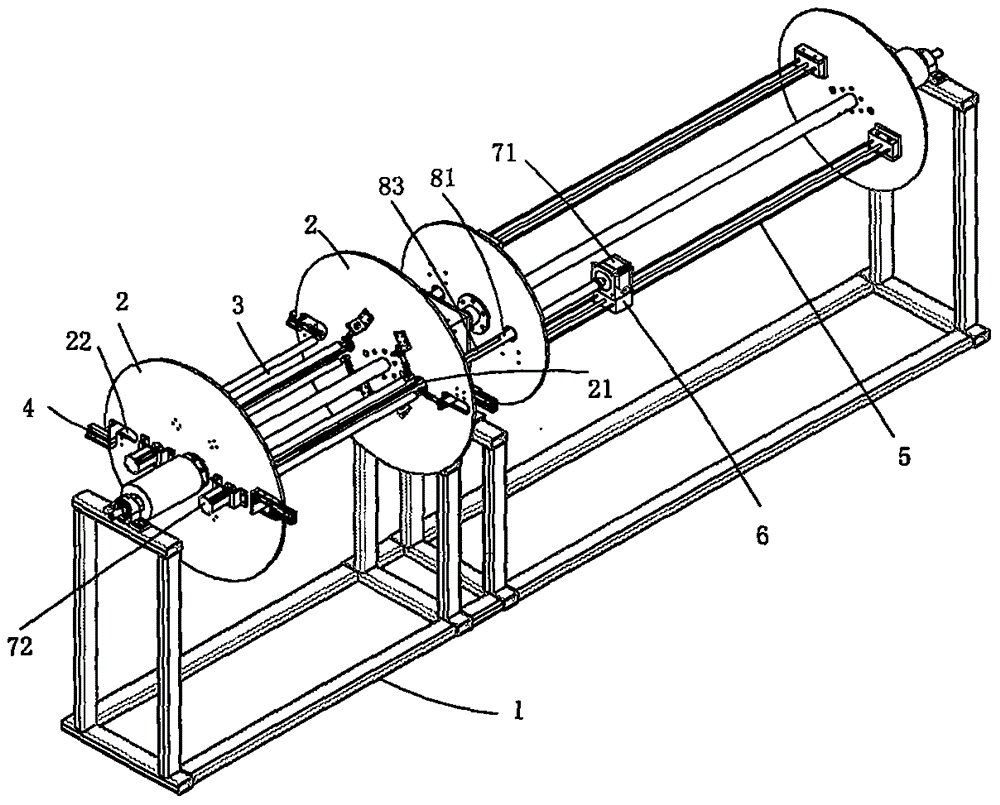

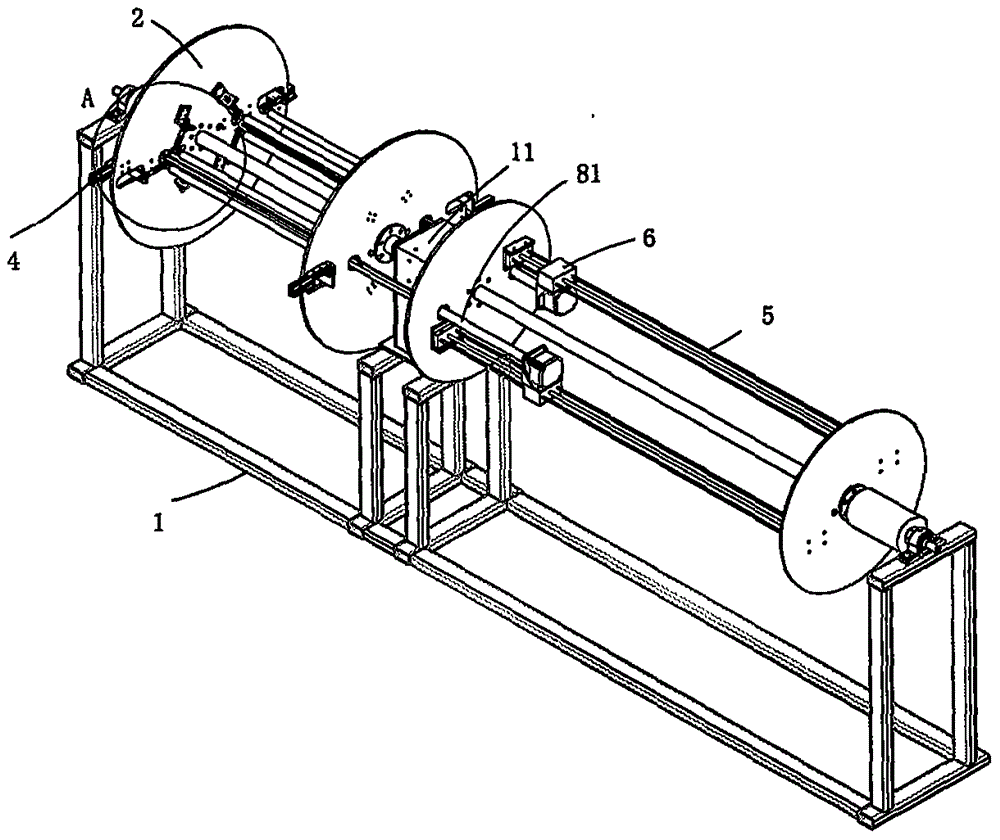

[0022] Such as Figure 1~2 As shown, a yoga mat rolling device includes a bracket 1, and the bracket 1 is provided with a bending station, a clamping part conveying mechanism, and a station switching motor 11. Two support pieces 2 are arranged vertically on the bracket 1, the support pieces 2 are disc-shaped, and two bending stations are arranged between the two support pieces 2, and each bending station is equipped with a set of clamping part conveying mechanism , The clamping part conveying mechanism is supported by another two disc-shaped supporting pieces 2. Driven by the station switching motor 11, the bending station and the clamping rod conveying mechanism equipped with it rotate synchronously.

[0023] Each bending station includes a bending constraining mechanism 3 arranged transversely between two supporting sheets 2 . Such as Figure 3-4 As shown, the bending constraining mechanism 3 includes a fixed pressure roller 31 and a moving pressure roller 32. The fixed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com