Two-photon polymerization 3D (three dimensional) printer and printing method

A two-photon polymerization and 3D printer technology, applied in the field of 3D printing, can solve problems such as the inability to print submicron structures and the inability of 3D printing technology to meet processing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

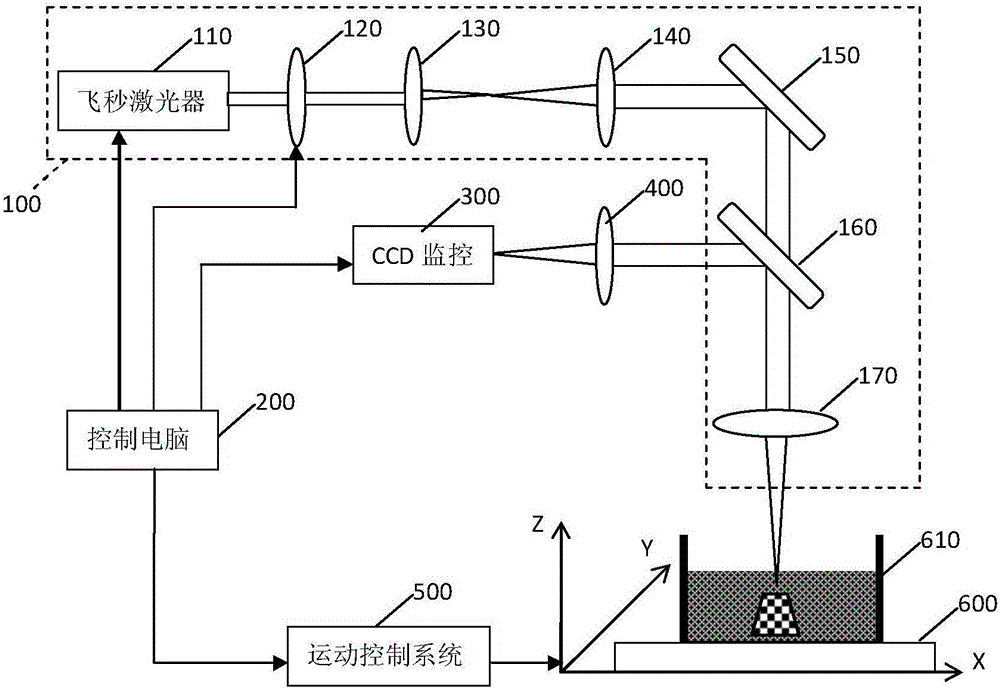

[0030] refer to figure 1 , in some embodiments, the two-photon polymerization 3D printer includes: femtosecond laser pulse system 100, control computer 200, CCD monitoring system 300, 3D precision slide table (submicron precision motion platform) 600, the motion control of 3D precision slide table System 500.

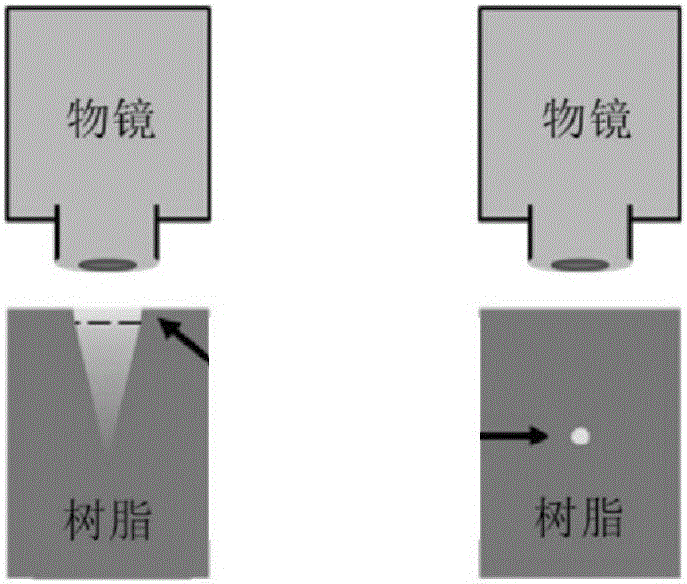

[0031] The femtosecond laser pulse system 100 has: a femtosecond laser 110 , an optical path switch 120 , an attenuator 130 , a beam expander 140 , a rotating mirror (mirror) 150 , and an objective lens 170 . The femtosecond laser 110 is used to generate 600-1000nm two-photon laser light. The laser passes through the optical path switch 120 , the attenuation sheet 130 , the beam expander 140 , the rotating mirror 150 and the objective lens 170 to focus the laser to a point to cross-link the photocurable resin. The optical path switch 120 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com