Novel lower-pressure-drop distribution plate applicable to multilayered bed

A distribution plate and multi-layer bed technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult operation, high energy consumption, and high requirements for booster fans, and reduce the pressure drop of multi-layer beds , fully responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

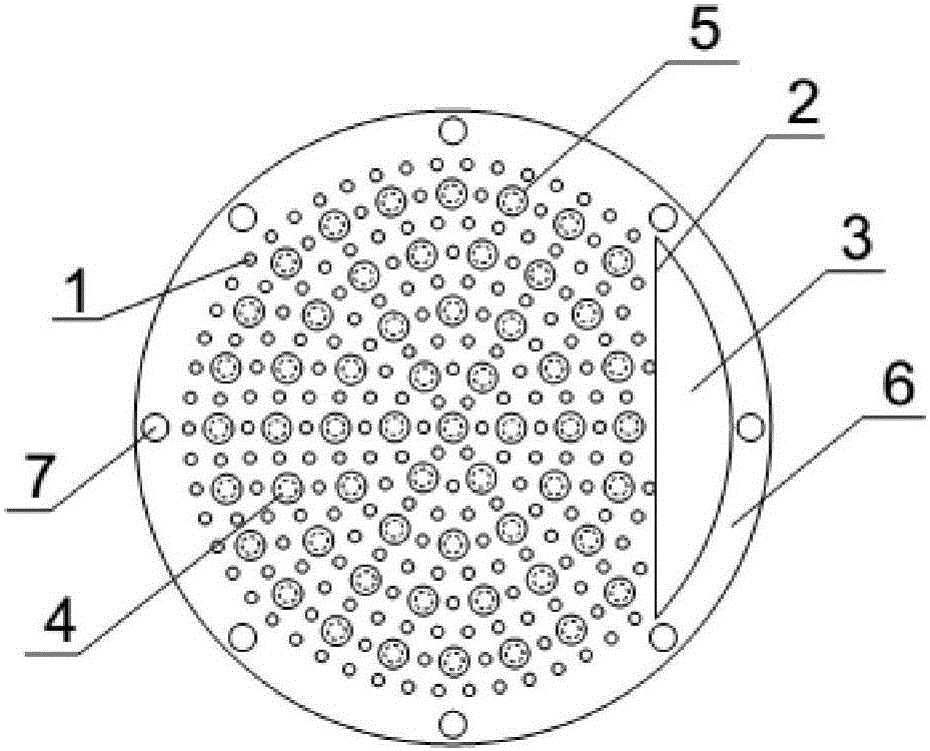

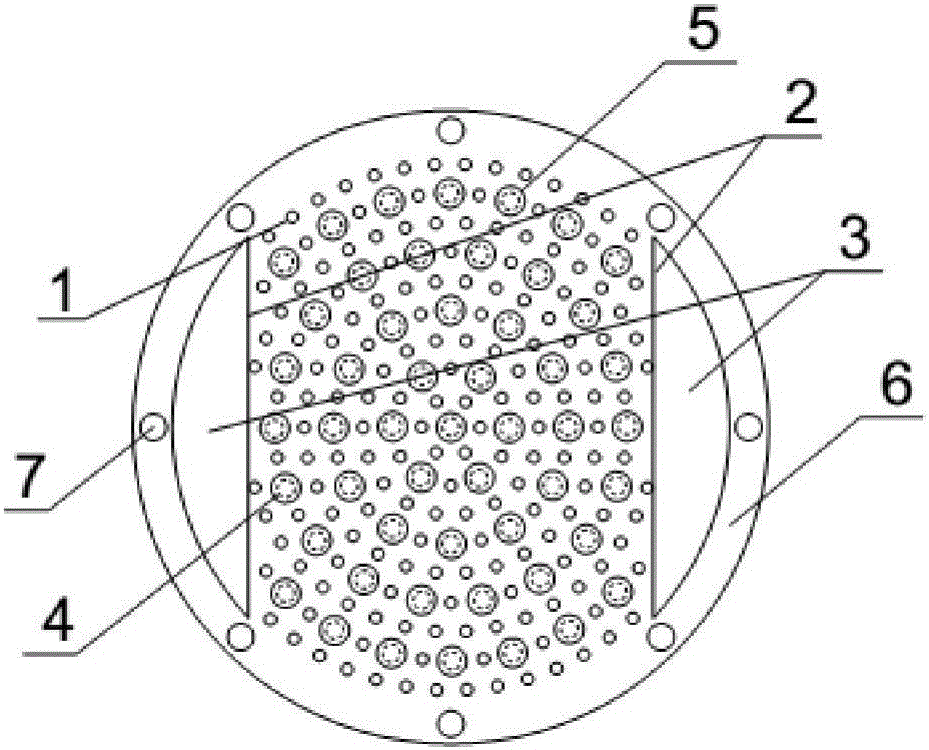

[0041] The distribution plate of the present invention is installed in the flue gas purification reaction tower, and the distribution plate is arranged in multiple layers to form multiple beds, such as Figures 1a-1d As shown, four new types of low-pressure drop distribution plates suitable for multi-layer beds, each type of distribution plate includes screen hole 1, overflow weir 2, material drop port 3, large hole nozzle 4 and its matching air cap 5, flange edge 6 and flange hole 7. The distribution plate is an incomplete circular plate, the gap is the material drop port 3, and the overflow weir 2 perpendicular to the distribution plate is arranged on the edge of the gap, and the large hole nozzles 4 are evenly distributed on the board and are equipped with a wind cap 5, and there are 5 large hole nozzles A sieve hole 1 is set in the gap, and the edge of the distribution plate is a flange edge 6 with a flange hole 7. Multiple distribution plates are installed on the wall of...

Embodiment 2

[0043] Such as figure 2 As shown, the distribution plate of the present invention is applied to a cross-flow multi-layer bed, and the cross-flow multi-layer bed includes: a flue gas inlet pipe 13, a flue gas outlet pipe 14, a spiral feed pipe 15, a feed bin 16, and a discharge pipe 17. The semicircle distribution plate 8, the single circular segment distribution plate 9 and the bottom circular distribution plate 10. The silo 16 is connected to the spiral feed pipe 15, the flue gas outlet pipe 14 and the spiral feed pipe 15 are connected to the highest layer of the tower, and the semicircle distribution plate 8 and multiple single circular segment shapes are installed in the tower from top to bottom through the flange connection. The distribution plate 9 and the circular distribution plate 10, when placing the distribution plates of each layer, make the discharge openings 3 of each distribution plate staggered left and right, and the discharge pipe 17 is connected to the botto...

Embodiment 3

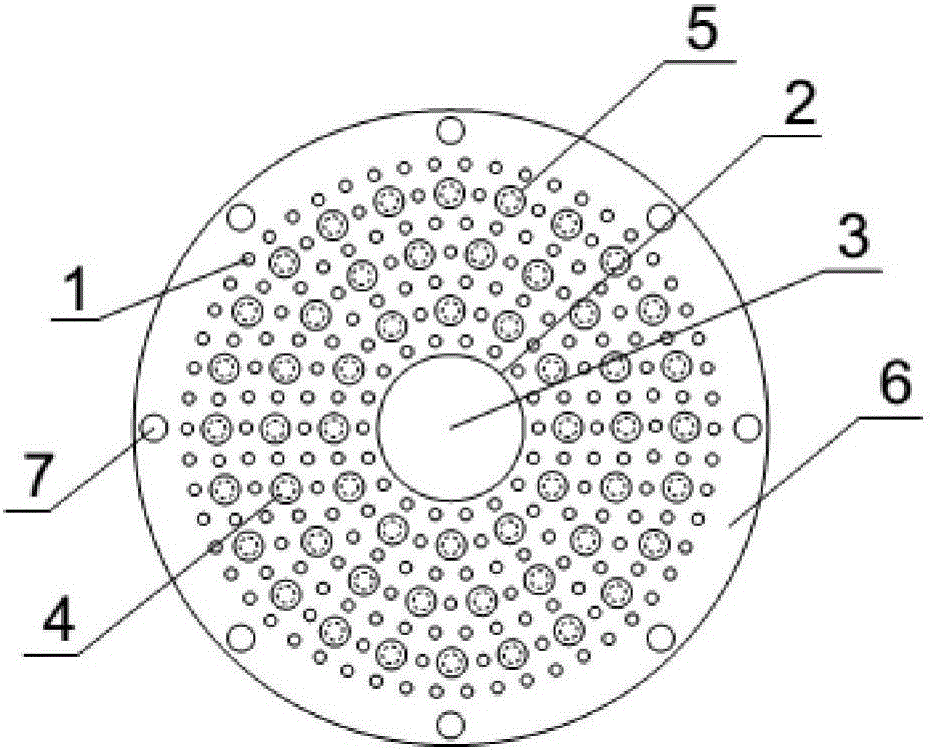

[0046] Such as image 3 As shown, the distribution plate of the present invention is applied to a concentrated-diffusion flow type multilayer bed. Concentrated diffusion flow type multi-layer bed mainly includes: flue gas inlet pipe 13, flue gas outlet pipe 14, spiral feeding pipe 15, silo 16, discharge pipe 17, circular distribution plate 10, symmetrical circular segment distribution plate 11 , The hole-shaped distribution plate 12.

[0047] The silo 16 is connected to the spiral feed pipe 15, the flue gas outlet pipe 14 and the spiral feed pipe 15 are connected to the highest layer of the tower, and the flange is used to connect the top-to-bottom symmetrical circular segmented distribution plate 11 and the notched hole-shaped distribution plate in the tower 12 are installed staggeredly, the last layer is a circular distribution plate 10, and the discharge pipe 17 is connected to the bottom layer of the bed.

[0048] The flue gas enters the reaction tower through the flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com