Element body of intelligent oil filtering device

An oil filter device and intelligent technology, applied in the field of machinery, can solve the problems of heating consumption of large electric energy, unfavorable emission reduction targets, pollution, etc., and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

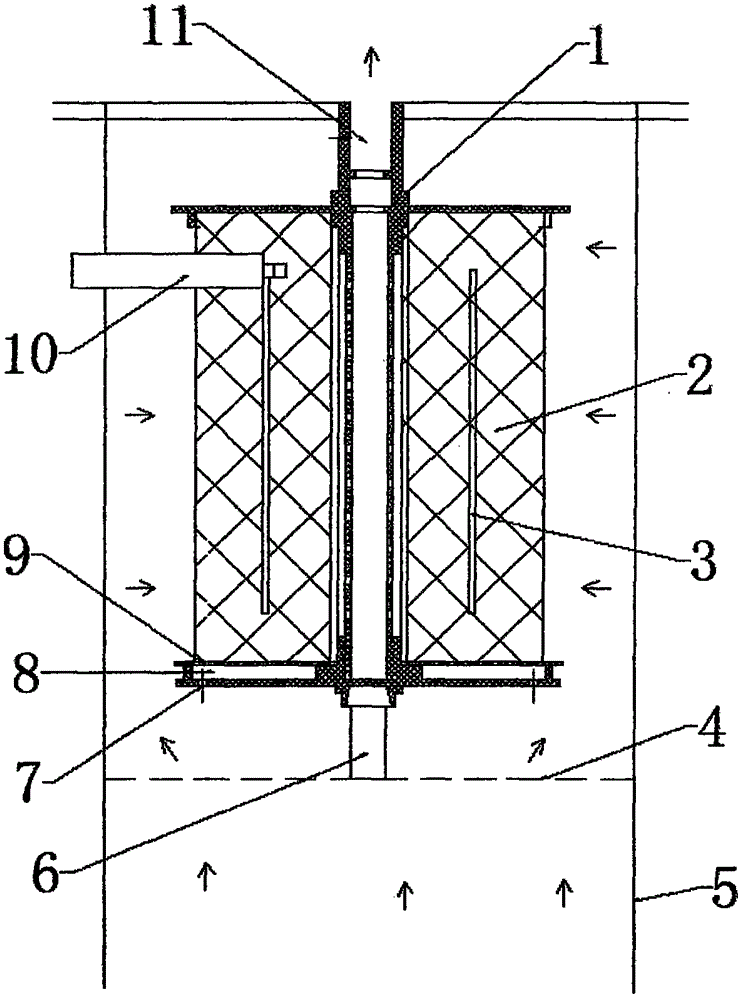

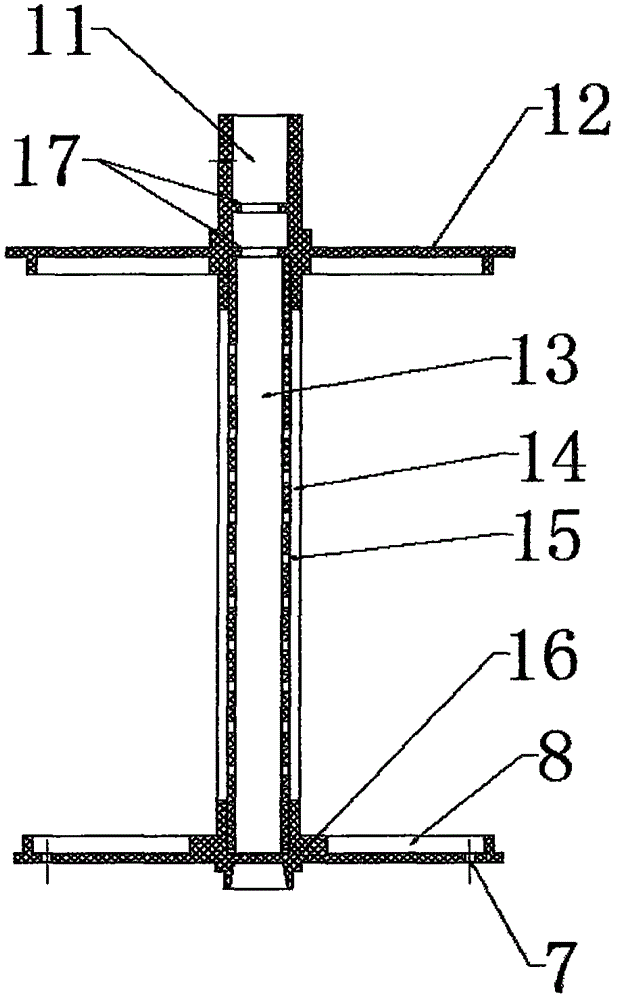

[0022] Embodiment 1 of the present invention such as Figure 1-2 As shown, the core body of the intelligent oil filter device includes: 1 skeleton, 2 filter material, 3 high-voltage electrode, 4 grounding electrode, 5 metal shell, 6 filter body support column, 7 is the regeneration through hole outside the dirt accumulation tank cavity, 8 A plurality of dirt accumulation grooves on the lower end cover, 9 net holders, 10 high pressure sockets, 11 oil outlets, 12 upper end covers of the frame, 13 intermediate core tubes on the frame, 14 multiple vertical ribs on the intermediate core tubes, 15 intermediate cores Pipe a plurality of oil through holes, 16 lower end caps, 17 oil outlet inner surface shape vertical ribs.

[0023] The skeleton 1 is compounded by the middle core tube 13, the upper end cover 12, and the lower end cover 16. There are multiple oil holes on the middle core tube 13, and one end of the middle core tube passes through the center of the upper end cover 12 as ...

specific Embodiment 2

[0030] The core body of the intelligent oil filter device, the process of oil purification and self-regeneration of the filter material are as follows:

[0031] (1) Metal particles, colloidal sludge, free water, and emulsified water in the directional flow oil under the action of an external electric field adsorb each other to form a dipole group, and at the same time, the filter material 2 polarized by the external electric field participates in the mutual adsorption;

[0032] (2) The directional oil flows to the outer circumference of the filter material 2, and the rough purification is completed while flowing. In the rough purification, the free water in the oil, the emulsified water with a particle size greater than 0.1mm, metal particles, and colloidal sludge are mutually The dipole group formed by the adsorption is adsorbed on the surface of the filter material when it reaches the outer ring surface of the filter material 2, and slides down along the surface under the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com