Surface-mounted magnetic lead screw and processing method thereof

A technology of magnetic lead screw and processing method, which is applied in the direction of permanent magnet clutch/brake, manufacture of motor generators, electrical components, etc. Process complexity, the effect of solving poor mechanical properties, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

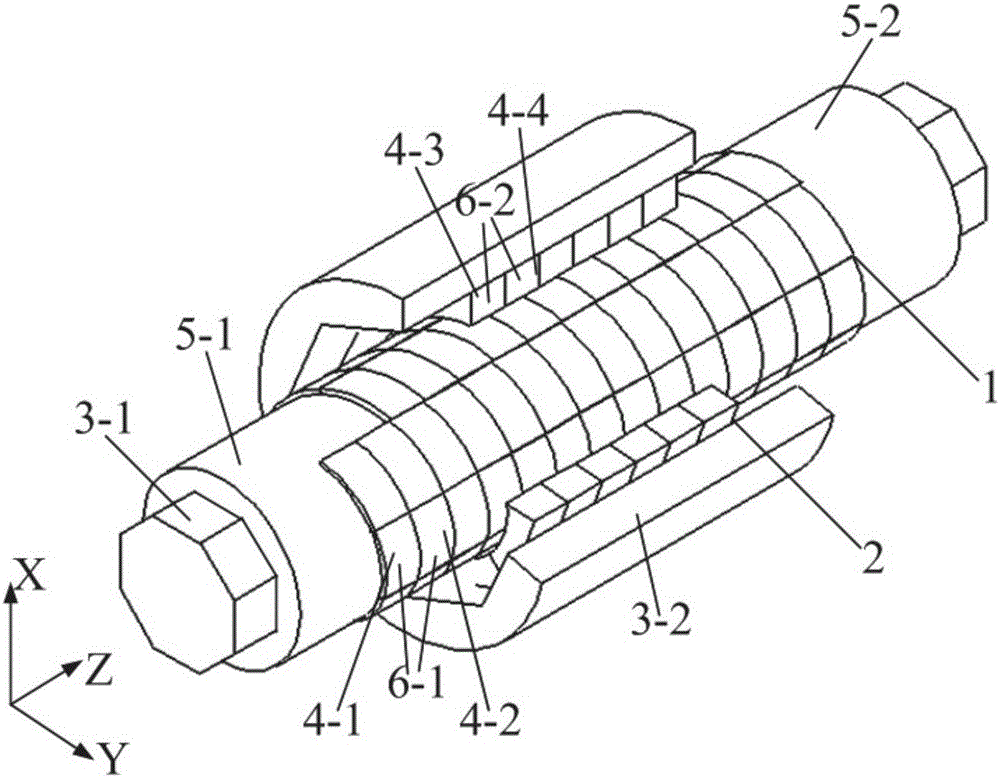

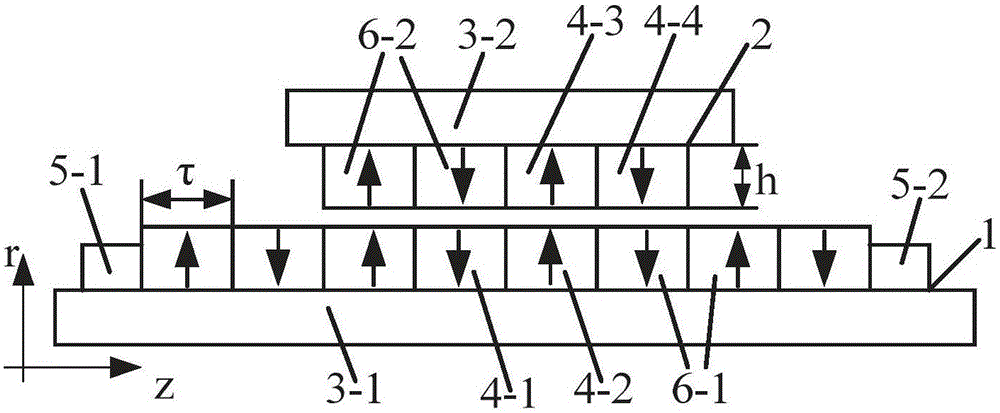

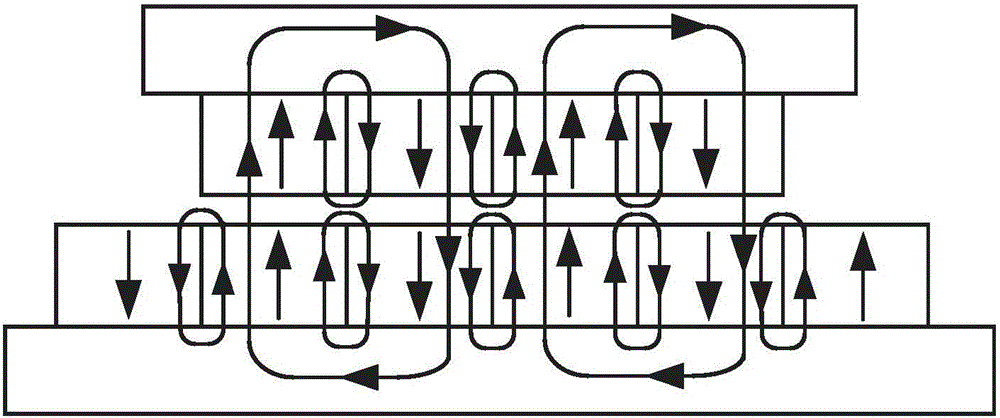

[0063] As a specific embodiment of the present invention, the present invention will be described below in conjunction with the accompanying drawings, as figure 1 with figure 2 As shown, the present invention is a surface-mounted magnetic screw and a processing method thereof, comprising a magnetic screw 1 and a magnetic nut 2 coaxial with an air gap therebetween. The magnetic nut 2 is empty sleeved outside the magnetic screw mandrel 1. The magnetic nut 2 rotates along the Z axis, and according to the working principle of the magnetic screw, the magnetic screw 1 moves linearly along the Z axis. Therefore, the axial length of the magnetic nut 2 is smaller than the axial length of the magnetic screw 1, and the specific size is determined according to the required characteristics of the magnetic screw.

[0064] The magnetic screw 1 is composed of a first permanent magnet a4-1, a first permanent magnet b4-2, an electrical iron rod 3-1, a limiter a5-1, and a limiter b5-2. Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com