Swing motor and electric clipper

A swing motor and control circuit technology, applied in electrical components, electromechanical devices, metal processing, etc., can solve the problems of small torque, electric clippers cannot be designed as wireless portable, and cannot generate working torque, etc., to achieve stable driving current , Energy-saving effect is obvious, the effect of long battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 provides a swing motor that can output a reciprocating swing motion.

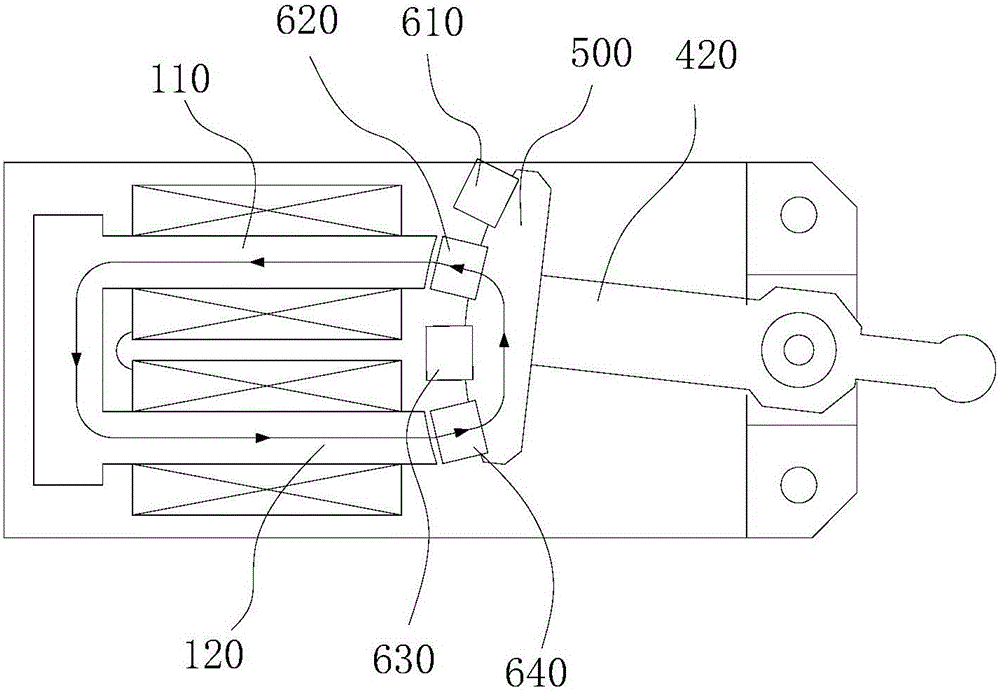

[0046] Please refer to figure 1 with 2 , the swing motor consists of:

[0047] A U-shaped yoke 100, the U-shaped yoke 100 has a first leg 110 and a second leg 120, coils 200 are respectively wound on the first leg 110 and the second leg 120;

[0048] A control circuit 300, the control circuit 300 is electrically connected to the coil 200, and generates alternating pulses, so that the end faces 111 and 121 of the two legs of the U-shaped magnetic yoke 100 generate alternating magnetic poles;

[0049] A swing arm 400 that can swing around a fulcrum. The swing arm 400 extends outward from the end faces 111 and 121 of the U-shaped magnetic yoke 100, and is bounded by the fulcrum. The end of the swing arm 400 close to the U-shaped magnetic yoke 100 is an inner arm 420. The end of the arm 400 away from the U-shaped yoke 100 is the outer arm 430;

[0050] The second yoke 500 (in order to di...

Embodiment 2

[0075] Embodiment 2 provides another swing motor.

[0076] Please refer to Figure 9 , the swing motor is improved on the structure shown in the first embodiment.

[0077] Specifically, elastic bodies 810 are provided on both sides of the swing arm 400 for absorbing the moment of inertia of the swing arm 400 when swinging in place, and the elastic characteristics of the elastic bodies 810 are curves of more than two degrees.

[0078] Wherein, the elastic body 810 is mainly used to absorb the moment of inertia of the swing arm 400 in the no-load state, and its elastic force increases with the increase of the compression stroke. The elastic characteristics of the elastic body 810 can ensure that the elastic body 810 does not have too much influence on the swing of the swing arm 400 under the load state (the swing distance of the swing arm 400 will be attenuated under the load state), only the swing arm 400 is squeezed too much under the no-load state Only the elastic body 810 ...

Embodiment 3

[0086] Embodiment 3 provides another swing motor.

[0087] Please refer to Figure 10 , the swing motor is improved on the structure shown in the first embodiment, and a resonant elastic member for generating resonance at a constant swing frequency is added.

[0088] Specifically, one end of the resonant elastic member is fixed on the fulcrum of the swing arm, and the other end is connected to the outer arm or the inner arm.

[0089] further, Figure 10 The resonant elastic member shown in is a straight spring steel wire, in addition, other shapes of elastic members can also be used instead, such as Figure 11 The middle portion of the resonant elastic member shown is curved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com