Single-phase magnetic-keeping operating mechanism

A technology of operating mechanism and magnetic retention, which is applied to the power device inside the switch, etc., can solve the problem of inability to feedback the operating speed information of the mechanism, and achieve the effect of low material and manufacturing cost, high reliability and intelligent monitoring, and avoiding friction and jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

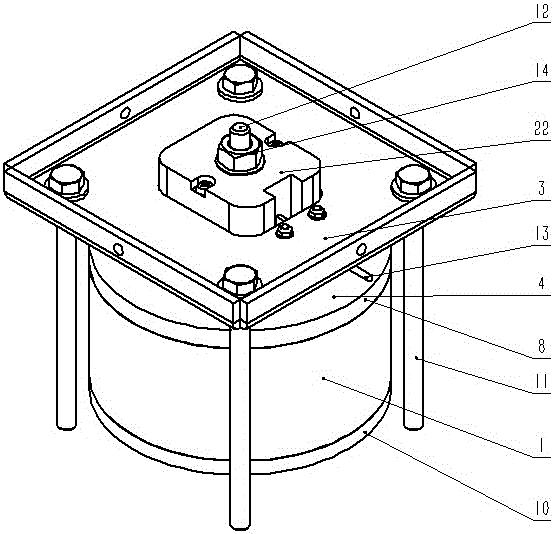

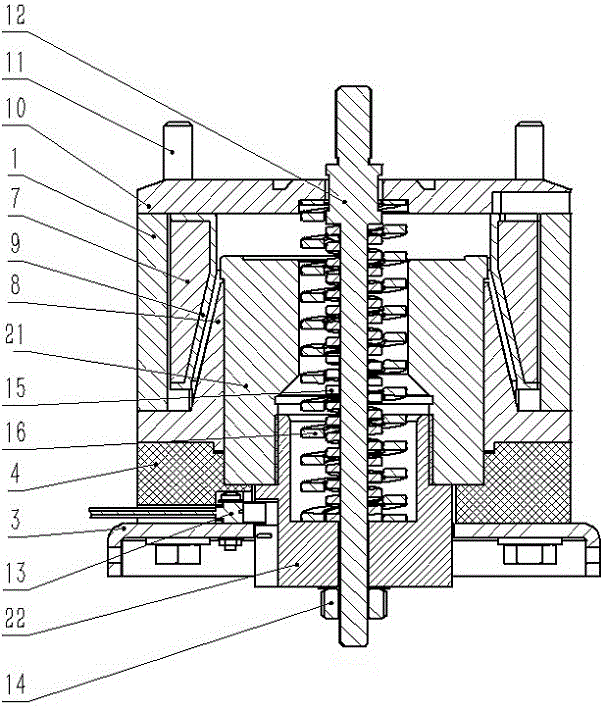

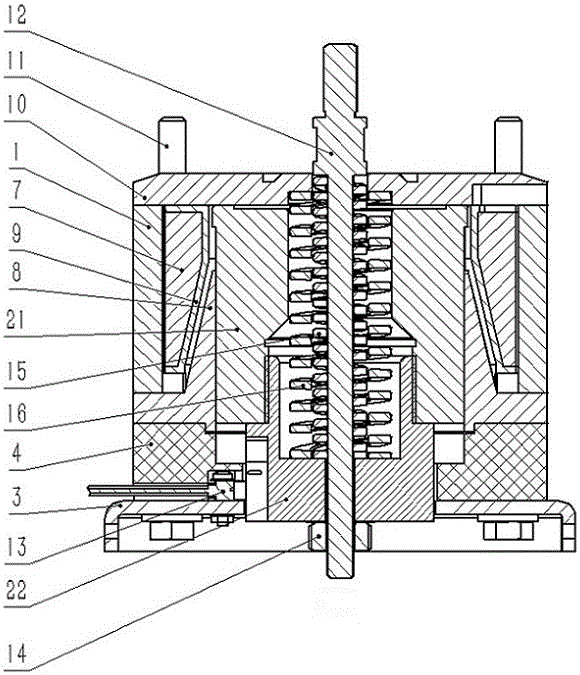

[0018] Such as Figure 1 to Figure 3 As shown, the present invention provides a single-phase magnetic holding operation mechanism, which includes an upper yoke 10, a lower yoke 8, a magnetic sleeve 1, a moving iron core assembly 2, a lower plastic end block 4 and a metal fixed pressure plate 3. A coil 7 is arranged between the upper yoke 10, the lower yoke 8, and the magnetic sleeve 1. The moving iron core assembly 2 includes a moving iron core 21 and a plastic cover 22 threaded on its lower part. The moving iron core 21 The middle passes through the operation pull rod 12, the opening spring 16 and the closing pressure spring 15. The photoelectric sensor element 13 is embedded in the lower plastic end block 4, and the signal line of the photoelectric sensor element passes through the metal fixing plate 3 and the lower plastic end block. The grooves between the end blocks 4 lead out, and the metal fixed pressure plate 3 is fixed and pressed to the installation plane by bolts 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com